All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

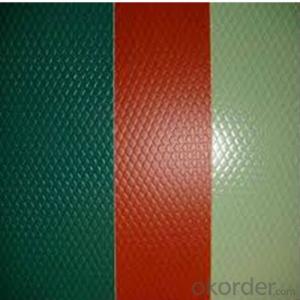

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Aluminum StripsView More

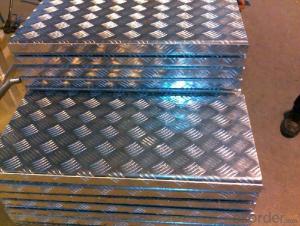

Aluminum SheetsView More

Aluminum CoilsView More

Aluminum FoilsView More

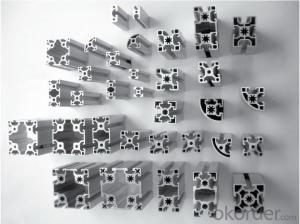

Aluminum ProfilesView More

Q & A

How is aluminum employed in the production of smartphones and tablets?

Aluminum is commonly used in the production of smartphones and tablets due to its lightweight, durable, and non-magnetic properties. It is often used to manufacture the frames, casings, and back panels of these devices. Aluminum helps provide structural integrity while keeping the overall weight of the device low. Additionally, its non-magnetic nature allows for better wireless signal reception and transmission.

Can you explain the aluminum production process, including the Bayer Process and the Hall-Héroult Process?

The aluminum production process involves two key processes: the Bayer Process and the Hall-Héroult Process.

The Bayer Process is used to extract aluminum oxide (alumina) from bauxite ore, which is the main source of aluminum. In this process, bauxite ore is first crushed and then mixed with a sodium hydroxide solution, resulting in a solution of sodium aluminate. Impurities are removed from the solution through precipitation and filtration, leaving behind a clear liquid called alumina liquor. The alumina liquor is then cooled and seeded with alumina crystals to initiate the precipitation process. Over time, the alumina crystals grow, and the remaining liquid is drained, leaving behind a white, powdery substance known as alumina.

The Hall-Héroult Process is the primary method for producing aluminum metal from alumina. In this process, alumina is dissolved in a molten cryolite electrolyte at a temperature around 950°C. The electrolyte serves as a solvent, lowering the melting point of alumina and facilitating the flow of electric current. Carbon anodes and a carbon-lined steel cathode are immersed in the electrolyte. When a direct electric current is passed through the electrolyte, electrolysis occurs. Oxygen ions from the alumina combine with the carbon anodes, producing carbon dioxide gas, while aluminum ions are reduced at the cathode, forming molten aluminum. The molten aluminum sinks to the bottom of the cell, where it is periodically tapped off and collected.

Overall, the aluminum production process involves extracting alumina through the Bayer Process and then converting it into aluminum metal through the Hall-Héroult Process. These processes are essential for the commercial production of aluminum, a widely used metal in various industries.

How do you choose the appropriate model of aluminum material?

When choosing the appropriate model of aluminum material, several factors need to be considered. These include the specific application or use case, the desired properties of the material (such as strength, corrosion resistance, or conductivity), the available budget, and any regulatory or industry requirements. It is essential to evaluate these factors and consult with experts or suppliers to determine the most suitable aluminum model that meets the needs and specifications of the project.

Wholesale Aluminum from supplier in Panama

Some of the benefits of partnering with us for all your Aluminum needs in Panama include:

1. Comprehensive Sales: We provide a wide range of Aluminum products, including sheets, plates, bars, tubes, and profiles, ensuring that you can find everything you need in one place. Our extensive inventory allows for quick and efficient delivery.

2. Quoting Services: Our dedicated team will provide you with accurate and competitive quotes for your Aluminum requirements. We take into account factors such as quantity, specifications, and delivery timelines to ensure that you receive the best possible price.

3. Technical Support: Our experienced technical team is available to assist you with any questions or concerns you may have regarding the use, installation, or maintenance of Aluminum products. We can provide guidance on the most suitable products for your specific project requirements.

4. Market Experience: With years of experience operating in the Panama region, we have developed a deep understanding of the local market dynamics. This knowledge enables us to provide valuable insights and expertise to help you make informed decisions and optimize your Aluminum procurement.

5. Trusted Supplier: As a subsidiary of CNBM, a Fortune Global 500 company, we have a proven track record of reliability and quality. You can trust us to deliver high-quality Aluminum products that meet your specifications and exceed your expectations.

6. One-Stop Solution: By partnering with us, you can streamline your Aluminum procurement process. We offer a comprehensive range of services, from sales to technical support, ensuring that all your needs are met under one roof.

7. Competitive Pricing: We leverage our global network and economies of scale to offer competitive pricing for our Aluminum products. We strive to provide excellent value for your investment, helping you save costs without compromising on quality.

Partner with us for all your Aluminum needs in Panama and experience the convenience, expertise, and reliability that we bring to the table. Contact us today to discuss your requirements and discover how we can support your projects.

1. Comprehensive Sales: We provide a wide range of Aluminum products, including sheets, plates, bars, tubes, and profiles, ensuring that you can find everything you need in one place. Our extensive inventory allows for quick and efficient delivery.

2. Quoting Services: Our dedicated team will provide you with accurate and competitive quotes for your Aluminum requirements. We take into account factors such as quantity, specifications, and delivery timelines to ensure that you receive the best possible price.

3. Technical Support: Our experienced technical team is available to assist you with any questions or concerns you may have regarding the use, installation, or maintenance of Aluminum products. We can provide guidance on the most suitable products for your specific project requirements.

4. Market Experience: With years of experience operating in the Panama region, we have developed a deep understanding of the local market dynamics. This knowledge enables us to provide valuable insights and expertise to help you make informed decisions and optimize your Aluminum procurement.

5. Trusted Supplier: As a subsidiary of CNBM, a Fortune Global 500 company, we have a proven track record of reliability and quality. You can trust us to deliver high-quality Aluminum products that meet your specifications and exceed your expectations.

6. One-Stop Solution: By partnering with us, you can streamline your Aluminum procurement process. We offer a comprehensive range of services, from sales to technical support, ensuring that all your needs are met under one roof.

7. Competitive Pricing: We leverage our global network and economies of scale to offer competitive pricing for our Aluminum products. We strive to provide excellent value for your investment, helping you save costs without compromising on quality.

Partner with us for all your Aluminum needs in Panama and experience the convenience, expertise, and reliability that we bring to the table. Contact us today to discuss your requirements and discover how we can support your projects.