All Categories

- - Steel Wire Rod

- - Steel Coils

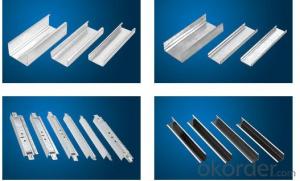

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How does coil temperature affect the quality of welding in steel fabrication?

Coil temperature plays a crucial role in determining the quality of welding in steel fabrication. When the coil temperature is too low, it can lead to poor fusion and inadequate penetration of the weld, resulting in weak joints and potential structural issues. On the other hand, if the coil temperature is too high, it can cause excessive heat input, leading to distortion, cracking, and even metallurgical changes in the steel. Therefore, maintaining the optimal coil temperature is essential to achieve proper weld formation, ensuring the integrity and strength of the fabricated steel structure.

What is the significance of coil set and crossbow in the manufacturing of metal containers?

Coil set and crossbow are two important factors in the manufacturing of metal containers as they directly impact the product's formability and quality. Coil set refers to the residual curvature or shape a metal coil retains after being uncoiled. It is crucial to control and minimize coil set as excessive curvature can lead to difficulties in the container forming process, resulting in dimensional inconsistencies and potential defects. Crossbow, on the other hand, refers to the distortion of a metal sheet where the edges are not parallel. This can be problematic as it affects the container's overall appearance and sealing capabilities. Therefore, understanding and managing coil set and crossbow are essential for producing high-quality metal containers that meet the required specifications and performance standards.

What is the role of tension in coil winding?

The role of tension in coil winding is to ensure that the wire is tightly wrapped around the coil form, allowing for consistent and uniform turns. This tension helps to prevent gaps or overlaps in the winding, ensuring optimal electrical performance and mechanical stability of the coil.

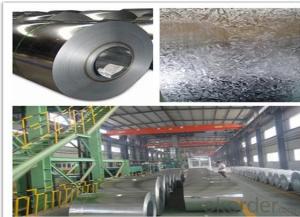

Wholesale Steel Coils from supplier in Malaysia

We understand the importance of quality and reliability when it comes to Steel Coils, which is why we only source our products from reputable manufacturers. Our Steel Coils are made from high-grade materials that meet international standards, ensuring durability and performance.

In addition to our wide range of Steel Coils, we also offer value-added services such as slitting, shearing, and custom fabrication. This allows us to provide tailored solutions to meet your specific project requirements. Our technical team is available to provide expert advice and support throughout the procurement process, ensuring that you get the right Steel Coils for your needs.

At our company, we prioritize customer satisfaction above all else. We strive to provide a seamless and hassle-free experience, from the initial inquiry to the final delivery. Our dedicated logistics team ensures timely and efficient delivery of your Steel Coils, regardless of the size or location of your project.

When you choose us as your Steel Coils supplier in Malaysia, you can expect competitive pricing without compromising on quality. We understand the importance of cost-effectiveness in today's market, and we work closely with our manufacturers to negotiate the best prices for our customers.

Whether you are a small business or a large corporation, we are confident in our ability to meet your Steel Coils needs. Our experienced team has successfully served clients in various industries, including construction, automotive, and manufacturing. We have the knowledge and expertise to provide the right solutions for your specific application.

Trust us to be your reliable Steel Coils supplier in Malaysia. Contact us today to discuss your requirements and let us exceed your expectations.

In addition to our wide range of Steel Coils, we also offer value-added services such as slitting, shearing, and custom fabrication. This allows us to provide tailored solutions to meet your specific project requirements. Our technical team is available to provide expert advice and support throughout the procurement process, ensuring that you get the right Steel Coils for your needs.

At our company, we prioritize customer satisfaction above all else. We strive to provide a seamless and hassle-free experience, from the initial inquiry to the final delivery. Our dedicated logistics team ensures timely and efficient delivery of your Steel Coils, regardless of the size or location of your project.

When you choose us as your Steel Coils supplier in Malaysia, you can expect competitive pricing without compromising on quality. We understand the importance of cost-effectiveness in today's market, and we work closely with our manufacturers to negotiate the best prices for our customers.

Whether you are a small business or a large corporation, we are confident in our ability to meet your Steel Coils needs. Our experienced team has successfully served clients in various industries, including construction, automotive, and manufacturing. We have the knowledge and expertise to provide the right solutions for your specific application.

Trust us to be your reliable Steel Coils supplier in Malaysia. Contact us today to discuss your requirements and let us exceed your expectations.