All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How do you conduct quality control testing on aluminum coil thickness and width?

To conduct quality control testing on aluminum coil thickness and width, a few methods can be employed. One common approach is using specialized measuring tools such as micrometers or calipers to accurately measure the thickness and width of the aluminum coil. These measurements can then be compared against the specified requirements to ensure they meet the desired standards. Additionally, non-destructive testing methods like ultrasonic or laser scanning can be utilized to evaluate the thickness and width of the coil without causing any damage. These methods enable manufacturers to identify any deviations or inconsistencies in the aluminum coil, allowing them to take corrective actions if necessary and maintain the desired quality standards.

How do you protect aluminum coils from physical damage during shipping?

To protect aluminum coils from physical damage during shipping, several measures can be taken. Firstly, the coils should be securely packaged using protective materials such as foam, bubble wrap, or corrugated cardboard to provide cushioning and prevent any direct impact. Additionally, using wooden crates or pallets can offer further stability and support. It is also essential to properly secure the coils within the packaging using straps or bands to prevent them from shifting or moving during transportation. Lastly, labeling the packaging as fragile and handling it with care instructions can alert handlers to exercise caution, minimizing the risk of physical damage.

Can aluminum coils be used in the manufacturing of advanced satellite communication systems?

Yes, aluminum coils can be used in the manufacturing of advanced satellite communication systems. Aluminum is a lightweight and durable material that offers excellent conductivity for transmitting and receiving signals. It also has good resistance to corrosion, making it suitable for the harsh conditions of outer space. Additionally, aluminum coils can be easily formed and shaped to meet the specific requirements of satellite communication systems.

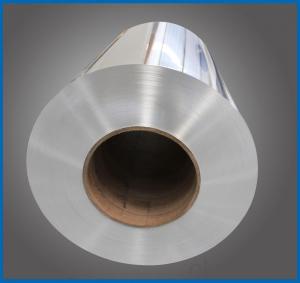

What are aluminum coils used for?

Aluminum coils are used in a variety of applications, including but not limited to, heating, ventilation, and air conditioning (HVAC) systems, electrical transformers, automotive parts, and packaging materials.

Wholesale Aluminum Coils from supplier in Bengal

Whether you require Aluminum Coils for construction, manufacturing, or any other application, we have the expertise and resources to meet your specific requirements. Our team of experienced professionals is dedicated to providing excellent customer service and ensuring that you receive the highest quality products.

With our strong connections to manufacturers and suppliers, we can offer competitive pricing and efficient delivery options. We understand the importance of timely and reliable supply, and we work closely with our partners to ensure that your orders are delivered on time and in perfect condition.

In addition to sales and procurement, we also provide technical support services. Our knowledgeable team is available to answer any questions you may have about Aluminum Coils, provide technical specifications, and offer guidance on the best products for your needs.

Whether you are a contractor, distributor, or end-user, we are committed to exceeding your expectations and delivering the best value for your investment. Contact us today to discuss your Aluminum Coils requirements in Bengal, and let us help you find the perfect solution for your projects.

With our strong connections to manufacturers and suppliers, we can offer competitive pricing and efficient delivery options. We understand the importance of timely and reliable supply, and we work closely with our partners to ensure that your orders are delivered on time and in perfect condition.

In addition to sales and procurement, we also provide technical support services. Our knowledgeable team is available to answer any questions you may have about Aluminum Coils, provide technical specifications, and offer guidance on the best products for your needs.

Whether you are a contractor, distributor, or end-user, we are committed to exceeding your expectations and delivering the best value for your investment. Contact us today to discuss your Aluminum Coils requirements in Bengal, and let us help you find the perfect solution for your projects.