All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

Can monolithic refractories be used for lining tundish gates in continuous casting?

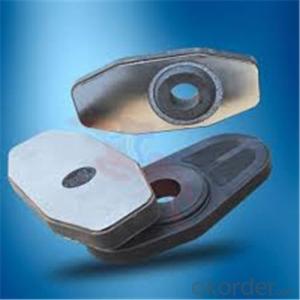

Yes, monolithic refractories can be used for lining tundish gates in continuous casting. Monolithic refractories offer several advantages such as easy installation, good thermal shock resistance, and high mechanical strength, making them suitable for lining tundish gates. They provide a durable and reliable lining that can withstand the harsh conditions of continuous casting operations.

How are monolithic refractories being used in the mining industry?

Monolithic refractories are extensively used in the mining industry due to their excellent thermal and chemical resistance properties. They are applied as linings in various high-temperature processing equipment such as smelters, furnaces, kilns, and reactors. These refractories provide insulation and protection against extreme temperatures, corrosive substances, and mechanical stress, ensuring the durability and efficiency of mining operations. Additionally, monolithic refractories are easy to install and repair, reducing downtime and maintenance costs for mining companies.

How do monolithic refractories provide resistance to chemical corrosion in reactors?

Monolithic refractories provide resistance to chemical corrosion in reactors through their unique composition and structure. They are made of a single, solid material that lacks joints or seams, eliminating potential weak points for chemical attack. These refractories are composed of highly stable and inert materials, such as alumina, silica, or magnesia, which are resistant to the corrosive effects of acids, alkalis, and other chemicals present in the reactor environment. Additionally, monolithic refractories offer excellent thermal shock resistance, preventing damage caused by rapid temperature changes. Overall, their homogeneous nature and carefully selected materials make monolithic refractories highly effective in providing protection against chemical corrosion in reactors.

How do monolithic refractories perform in high-velocity combustion environments?

Monolithic refractories are well-suited for high-velocity combustion environments due to their high thermal shock resistance and excellent erosion resistance. They can withstand the intense heat and rapid temperature changes in such environments without compromising their structural integrity. Additionally, their ability to bond and form a continuous, seamless lining allows them to effectively withstand the turbulent flow of gases and particulates, making them highly reliable in high-velocity combustion applications.

How do monolithic refractories handle high-pressure gas flow?

Monolithic refractories are designed to handle high-pressure gas flow effectively due to their composition and structural properties. They are made from a single, unified material, which eliminates the presence of joints or seams that could potentially weaken under high-pressure conditions. Additionally, monolithic refractories have excellent thermal conductivity and high resistance to thermal shock, allowing them to withstand the intense heat generated by high-pressure gas flow without cracking or breaking. Their dense and homogeneous structure ensures that they can effectively contain and channel the high-pressure gas, making them a reliable choice for such applications.

Wholesale Monolithic Refractories from supplier in Australia

Whether you are in need of Monolithic Refractories for industrial applications or construction projects in Australia, we are here to assist you every step of the way. Our team of experts can provide you with comprehensive sales and technical support, ensuring that you find the right Monolithic Refractories products for your specific requirements.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to deliver convenient and efficient procurement solutions for Monolithic Refractories across Australia. Our extensive product range includes various types of Monolithic Refractories, such as castables, gunning mixes, ramming mixes, and mortars, among others. We work closely with leading manufacturers and suppliers to ensure that we offer high-quality products that meet industry standards.

With our years of experience in the Australian market, we understand the unique challenges and demands of various industries. Whether you are in the steel, cement, glass, or petrochemical industry, we can provide invaluable expertise and guidance to ensure the success of your projects.

Beyond our expertise in Monolithic Refractories, we also want to take a moment to introduce you to the beauty and wonders of Australia. From the breathtaking Great Barrier Reef, the world's largest coral reef system, to the awe-inspiring Uluru in the Outback, Australia offers a diverse range of natural landscapes that are truly captivating. The country is also known for its unique wildlife, including kangaroos, koalas, and the iconic platypus.

In addition to its natural wonders, Australia is home to vibrant cities like Sydney and Melbourne, where you can experience a thriving arts and culture scene. From world-class museums and galleries to bustling markets and festivals, there is always something exciting happening in these cities. The friendly and laid-back lifestyle of Australians adds to the charm of the country, making it a welcoming and enjoyable destination for both work and leisure.

So, whether you are looking for Monolithic Refractories solutions or planning to explore the wonders of Australia, we are here to assist you. Contact us today to discuss your needs and let us provide you with the best possible solutions for your projects.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to deliver convenient and efficient procurement solutions for Monolithic Refractories across Australia. Our extensive product range includes various types of Monolithic Refractories, such as castables, gunning mixes, ramming mixes, and mortars, among others. We work closely with leading manufacturers and suppliers to ensure that we offer high-quality products that meet industry standards.

With our years of experience in the Australian market, we understand the unique challenges and demands of various industries. Whether you are in the steel, cement, glass, or petrochemical industry, we can provide invaluable expertise and guidance to ensure the success of your projects.

Beyond our expertise in Monolithic Refractories, we also want to take a moment to introduce you to the beauty and wonders of Australia. From the breathtaking Great Barrier Reef, the world's largest coral reef system, to the awe-inspiring Uluru in the Outback, Australia offers a diverse range of natural landscapes that are truly captivating. The country is also known for its unique wildlife, including kangaroos, koalas, and the iconic platypus.

In addition to its natural wonders, Australia is home to vibrant cities like Sydney and Melbourne, where you can experience a thriving arts and culture scene. From world-class museums and galleries to bustling markets and festivals, there is always something exciting happening in these cities. The friendly and laid-back lifestyle of Australians adds to the charm of the country, making it a welcoming and enjoyable destination for both work and leisure.

So, whether you are looking for Monolithic Refractories solutions or planning to explore the wonders of Australia, we are here to assist you. Contact us today to discuss your needs and let us provide you with the best possible solutions for your projects.

Hot Search

- Monolithic Refractories in Eritrea

- Ceramic Fiber Products in Nicaragua

- Refractory Bricks in Botswana

- Raw Materials For Refractory in Syria

- Ceramic Fiber Products in Australia

- Monolithic Refractories in Belarus

- Raw Materials For Refractory in Comoros

- Refractory Bricks in Monaco

- Refractory Bricks in Burundi

- Raw Materials For Refractory in Spain