Vacuum Bagging Film-vacuum infusion process

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Vacuum Bagging Film

Product Description

Vacuum bagging film is widely used in the composites industry, in vacuum infusion process, vacuum bagging pressure process and autoclave process. It is a technique in which you create uniform pressure to the surfaces of the obiect inside of a bag, holding parts together while the adhesive cures. Pressurizing a composite lamination serves several functions. It removes any trapped air between layers and provides pressure that prevents shifting of fiber orientation during cure. It also reduces humidity and improves the fiber-to-resin ratio in the composite part.

Technique Data

Temperature:150℃

Thickness:65μm,50μm,75μm

Width:≤14m

Length:Tailored

Density:1

Colour:yellow

Longitudinal Tensile Strength:>35MPA

Tensile Strength crosswise:>40MPA

Longitudinal elongation:>300%

Elongation crosswise:>350%

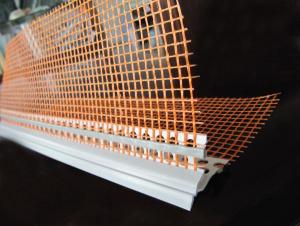

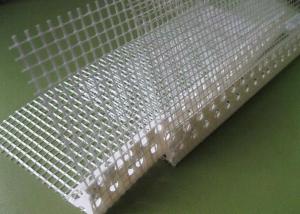

- Q:What's the corner line?

- The invention has the following characteristics and advantages: high grade of products, surface brightness, color varieties, both inside and outside the corner line can meet the requirements of various construction in the corner, if want to change the size of the finished product with ordinary sandpaper can reach. Scratch damage, easy repair, fire retardant, anti aging, anti impact, non-toxic, no radioactive green. Has the advantages of simple structure, good strength, simple manufacturing process, easy to use.

- Q:Plastic products surface of weld line, how to deal with the clip

- Injection molding is the process by which molten plastic enters the mold cavity through a gate and forms a product of a certain shape after cooling. Many products are through holes, angle, plastic flow of the melt mold wall damping on their will, local damping angle will be greater, so even if there is no hole products, molten plastic flow velocity inside will be different, because the velocity is not uniform, at the same time, it is not possible to fill the whole cavity, plastic materials, two different flow rate of molten in a cavity at the rendezvous, which we often say that the clip wave, also known as the joint line. This is the formation of the clamping mechanism.

- Q:Ask about the product performance and advantages of DJ series corner band sawing machines!

- If you are interested, you can check the relevant product information at the super CNC website, and hope that my answer will help you.

- Q:Large angle hinge is used at the corner of the cabinet

- 90 degree plane hinge ~ 180 degree hingeThe 90 degree hinge is connected to the two door panelsThe 180 hinge is mounted on the side plateBut this has a higher demand for hingesIf the quality is not good, the sink will not sink

- Q:Does it need extra money to decorate the corner of the plaster line?

- This is extra. Corner and corner are 2. The corner is more expensive than the corner line

- Q:What do you mean by corner steering of Bao Chun 730ABS steering wheel?

- The steering wheel sensor usually uses three mechanical structures to measure the angle and the number of turns. The large gear rotates along with the steering tube column, and the teeth of the two pinions differ by 1, and are fixed in the body with the sensor casing, and do not rotate with the steering wheel. The two small gears are respectively collected with the rotation angle of the steering wheel, and because of the difference of one tooth, the number of different turns will be different from the specific angle, and the absolute rotation angle of the steering wheel can be obtained by calculation.

- Q:Pcliao injection of smooth surface not light is going on

- This defect is commonly believed to occur frequently during die filling and pressure holding. In fact, dark spots appear near the gate and usually occur at the beginning of the injection cycle. Tests show that the occurrence of surface slip is actually due to the injection speed, or rather the flow velocity at the tip of the melt flow.

- Q:What are the applicable industries of corner labeling machines?

- Applicable products: all kinds of cartons, such as poker boxes, mobile phone packaging boxes, etc.. And widely used in printing, food, daily chemicals, electronics, medicine and other industries.

- Q:What corner is the corner cabinet with five corners?

- The inspection report is indispensableWhen asked about the test report, many businesses will produce raw materials inspection reports, in fact, issued by the state requirements, furniture is finished product testing report, but also need to indicate the content of formaldehyde. Raw materials testing report can not replace the finished product inspection report, consumers need to polish their eyes at this time, to prevent some businesses deceptive.

- Q:Microcrystalline stone xinzhongyuan ceramics why stick after a period of time where the angle is easy to crack?

- Microcrystalline stone have generally avoided cutting angle of L, and the corner if you are generally cut shop workers will have cracks, then can not see, but a long time stress release crack will be larger, if it is a thin transparent ceramics to the occurrence of this phenomenon, there is a possibility that the sintering temperature of microcrystalline stone will not lead to this phenomenon, there is a buy - stone, I suggest you buy a Baird.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Vacuum Bagging Film-vacuum infusion process

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches