Underground Epoxy Coated Spiral Welded Corrugated Composite Steel Pipe for Mining

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Underground Epoxy Coated Spiral Welded Corrugated Composite Steel Pipe for Mining

Press grade: Maximum PN -0.097MPa

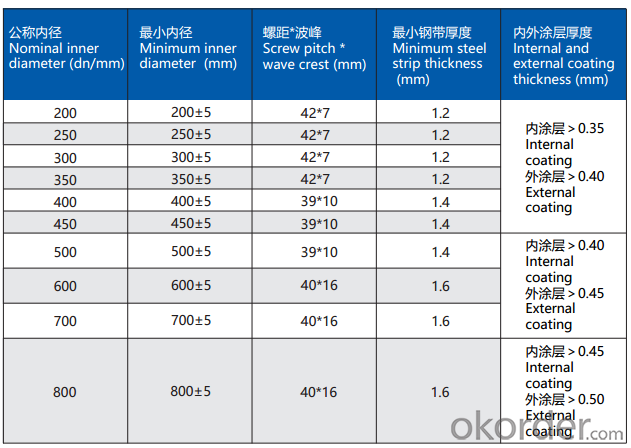

Size: DN200MM-DN800MM

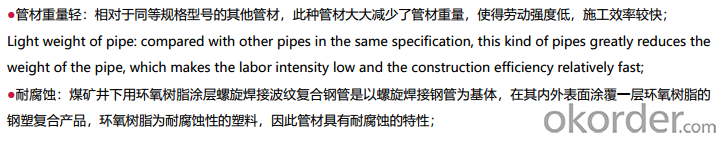

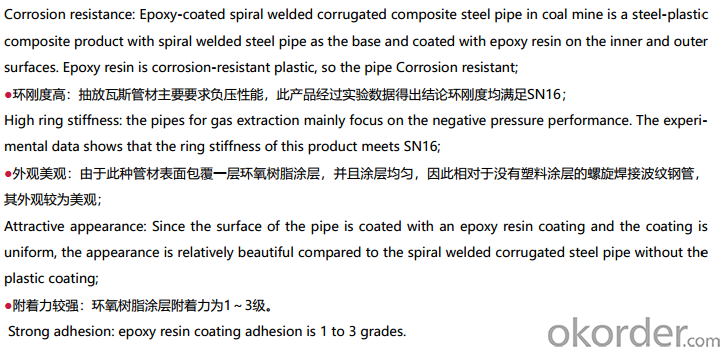

Features:

Specification

We own three industry bases for manufacturing pipes, fittings and new materials, including the biggest production line of steel wire reinforced PE composite pipe in the world, and top advanced PE pipe production line.

We get long term cooperation with leading material suppliers in the world and professionally provide the pipeline system solutions of matched products and technical cases by the whole industry chain from materials R&D to pipeline engineering installation.

- Q:What is the role of steel pipes in the construction of bridges?

- The role of steel pipes in the construction of bridges is primarily to provide structural support and stability. Steel pipes are commonly used in bridge construction to form the framework and support the weight of the bridge deck and other components. They are also used to carry various utilities such as water, gas, and electricity across the bridge. Additionally, steel pipes are durable, resistant to corrosion, and have high strength-to-weight ratio, making them an ideal choice for constructing bridges that can withstand heavy loads and harsh environmental conditions.

- Q:What is the difference between internal threading and external threading of steel pipes?

- Steel pipes can be threaded using two different methods: internal threading and external threading. The difference between these methods lies in where the threads are created. Internal threading involves cutting threads on the inside surface of the steel pipe. To do this, a tool or die is used to remove material from the inner diameter of the pipe, resulting in a helical groove. These threads are useful for connecting the pipe to other components, such as fittings or valves. On the other hand, external threading involves cutting threads on the outside surface of the steel pipe. This process requires the use of a threading die or a lathe to remove material from the outer diameter, leaving a helical groove. These external threads allow the pipe to be connected to other components or fittings with corresponding internal threads. The choice between internal and external threading depends on the specific application and project requirements. Internal threading is often preferred when the pipe needs to be connected to components with external threads, like fittings or valves. External threading, on the other hand, is typically used when the pipe needs to be connected to components with internal threads, or when it needs to be screwed into a threaded hole or coupling. In conclusion, the primary difference between internal and external threading of steel pipes is the location of the threads – internal threads are cut on the inside surface, while external threads are cut on the outside surface. The choice between these methods depends on the specific application and the type of connections needed.

- Q:How does the price of steel pipes vary based on market demand?

- The price of steel pipes varies based on market demand because when the demand for steel pipes is high, the prices tend to increase as suppliers can charge more for their products. Conversely, when the demand is low, the prices may decrease as suppliers may need to offer discounts or special deals to attract buyers. Essentially, the price of steel pipes fluctuates with changes in market demand.

- Q:What are the different types of coatings used on steel pipes?

- There are several different types of coatings used on steel pipes, including polyethylene, fusion bonded epoxy, coal tar enamel, and asphalt enamel. These coatings provide protection against corrosion, abrasion, and other forms of damage, ensuring the longevity and durability of the steel pipes.

- Q:How do you calculate the flow rate in a steel pipe?

- When calculating the flow rate in a steel pipe, several factors must be taken into consideration. The primary factor to consider is the cross-sectional area of the pipe, which can be determined using the formula A = πr², where A represents the cross-sectional area and r represents the radius of the pipe. Afterwards, it is necessary to ascertain the velocity of the fluid moving through the pipe. This can be accomplished by utilizing the equation v = Q/A, where v denotes the velocity, Q represents the volumetric flow rate, and A represents the cross-sectional area of the pipe. To determine the volumetric flow rate, one can employ the equation Q = AV, where Q represents the volumetric flow rate, A represents the cross-sectional area, and V represents the average velocity of the fluid. Furthermore, it is essential to take into account the properties of the fluid being transported through the pipe. Factors such as density and viscosity can impact the flow rate. In conclusion, the flow rate in a steel pipe can be calculated by determining the cross-sectional area of the pipe, calculating the velocity of the fluid, and considering the properties of the fluid being transported.

- Q:How do you calculate the stress in a steel pipe?

- To calculate the stress in a steel pipe, you need to determine the applied force or load acting on the pipe and divide it by the cross-sectional area of the pipe. This will give you the stress value, which is typically measured in units of force per unit area (such as pounds per square inch or pascals).

- Q:What are the different types of coatings used for external protection of steel pipes?

- There are several types of coatings commonly used for the external protection of steel pipes, including fusion bonded epoxy (FBE) coatings, three-layer polyethylene (3LPE) coatings, three-layer polypropylene (3LPP) coatings, and coal tar enamel (CTE) coatings. Each of these coatings provide different levels of corrosion resistance and durability, depending on the specific requirements of the project or application.

- Q:Can steel pipes be used for natural gas processing plants?

- Yes, steel pipes can be used for natural gas processing plants. Steel pipes are commonly used in the oil and gas industry due to their high strength, durability, and resistance to corrosion. They can safely transport natural gas and are capable of withstanding the high pressure and temperature conditions typically found in processing plants.

- Q:What are the typical lengths of steel pipes?

- The typical lengths of steel pipes vary depending on the industry and application. However, common lengths for steel pipes range from 18 to 40 feet.

- Q:What are the different methods of coating steel pipes?

- There are several methods of coating steel pipes, including fusion bonded epoxy (FBE) coating, liquid epoxy coating, polyethylene (PE) coating, and polyurethane (PU) coating. Each method offers unique advantages and is chosen based on factors such as the desired level of corrosion protection, application environment, and project requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Underground Epoxy Coated Spiral Welded Corrugated Composite Steel Pipe for Mining

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords