Wexan Pipes

Wexan Pipes Related Searches

Characteristics Of Hydrochloric Acid Wrought Iron Table Lamps Classification Of Inorganic Pharmaceuticals Sg Iron Grades Chemical Composition Gray Iron Microstructure Spheroidal Iron Amiantit Grp Pipes Gre Pipes Wexan PipesHot Searches

Solar Hot Water Collectors For Sale Stone Hot Water Bottles For Sale Ex Display Log Cabins For Sale Gumbo Bowls For Sale Suzuki Propellers For Sale Freight Crates For Sale Outhouse Sheds For Sale Buy Alabaster For Carving Pedestal Fan With Water Spray Price Mini Inverter With Battery Online Shopping Coronation Hot Water Bottle Price ppr pipe manufacturers in saudi arabia Price Of Water Cooler ppr pipes manufacturers in europe ppr pipes manufacturers in india Buy Hot Water Bag ppr pipes price list philippines ppr type 3 Costco Water Cooler ppr pipes specificationsWexan Pipes Supplier & Manufacturer from China

Okorder.com is a professional Wexan Pipes supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Wexan Pipes firm in China.Hot Products

FAQ

- nan

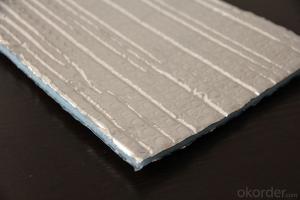

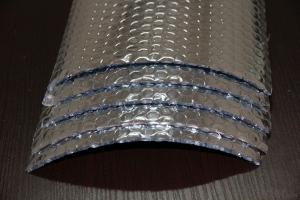

- Glass wool: Glass wool has no shots, having less dust and little irritation to skin and respiratory system as well as light weight, able to be processed to products with long length based on design requirements. It entails less waste, easy to construction. It uses amorphous cellulose which is soft and lathy with no shots, able to serve for more than 20 years. So, in terms of price per ton, rock wool is cheaper than glass wool. But in terms of price per square meter, the prices of glass wool and rock wool are basically flat. If various factors like effect, construciton, service life, safety and bearing structure are took into account comprehensively, glass wool then is more economical. Rock wool: It contains a high content of shots and much dust. It is high irritable to skin and respiratory system, keeping heavy weight, so it cannot be processed for a long time. It entails much waste, difficult to construction. It uses crystalline fiber, which has a high content of shots, is shoyt and unstable. If used for a certain time, its shots and short?fiber will sink, making it unable to maintain a uniform shape, which will seriously affect the insulation effect and needs to be replaced consequently. And the replacement cycle is shorter than 10 years.

- Is the glass wool poisonous,

- if the glass fiber deposition in the lungs, the human lungs will cause serious harm,

- nan

- what is the meaning of your words! are you asking the size! (I am a thermal insulation material wholesalers and if you have any questions please ask me)

- nan

- Glass cotton in the market is generally 16kg / m? to 64kg / m?. I have also heard about glass cotton with high unit weight, but the higher the unit weight is, the higher the production requirements are, and the boards are more fragile. Glass cotton are manufactured to meet the requirement of large-area pave, apart from the unique thermal insulation property, they are good at fireproofing, shock and sound absorption.

- nan

- It can be applied and it is just a problem of construction. Some are easier in construction and some are difficult.

- nan

- Glass wool, a man-made inorganic fiber, belongs to a kind of glass fiber. It is a spongiform material made through fibration of melten glass. It is an inorganic fiber whose chemical components belong to glass, having good formability, low bulk density, low thermal conductivity, good thermal insulation and sound absorption, corrosion resistance and chemical stability. For centrifugal glass wool whose thickness exceed 5 cm and unit weight is 16Kg / m3, the sound absorption coefficient of low frequency125Hz is about 0.2, and that of middle and high frequency is close to 1. When the thickness continues to increase from 5cm, the low-frequency sound absorption coefficient also increase gradually. When the thickness is greater than 1m or more, 125Hz low frequency sound absorption coefficient will also be close to 1. Thicknesses of acoustic glass wools often used in architectural acoustics are 2.5cm, 5cm, 10cm, and unit weights are16,24,32,48,80,96,112kg / m3. centrifugal glass wool whose thickness is 5 cm and unit weight is 12-48kg / m3 is usually used.

- nan

- The main raw materials of good centrifugal glass wools which are made of industrial chemicals like borax are natural ores like quartz sand, limestone, and dolomite, with some pure alkali.

- nan

- Almost the same, no significant difference. You can send me message if you have some trouble.