Uniaxial Geogrid Specifications

Uniaxial Geogrid Specifications Related Searches

Led For Cannabis Growing Fiberglass Panels For Roofing Geogrid For Retaining Wall Geogrid For Erosion Control Geogrid For Road Stabilization Geogrid For Gravel Roads Geogrid For Gravel Driveway Geogrid For Roads Geogrid For Driveway Geogrid For SlopesHot Searches

Inverter Size For Solar System Used Metal Folding Chairs For Sale Large Metal Containers For Sale Metal Shop Cabinets For Sale Metal Shipping Crates For Sale Solar Panel Inverter Size Cost Of Drywall Per Sheet Large Size Aluminum Foil Aluminum Foil Market Size Solar Inverter Market Size Solar Inverter Size Chart Solar Inverter Size Aluminum Channel Stock Sizes hdpe pipe specifications polypropylene pipe specifications 1 2 Inch Type X Drywall Cost Of Drywall 1 2 Type X Drywall Metal Roof Tiles Prices Metal Furniture CompanyUniaxial Geogrid Specifications Supplier & Manufacturer from China

Okorder.com is a professional Uniaxial Geogrid Specifications supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Uniaxial Geogrid Specifications firm in China.Hot Products

FAQ

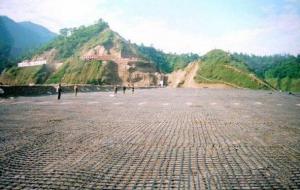

- The design guidelines for geogrid-reinforced structures typically include factors such as selecting the appropriate geogrid material, determining the required strength and stiffness properties, spacing and orientation of the geogrid layers, and proper connection details. Additionally, the guidelines may address slope stability, settlement control, and construction considerations to ensure the overall stability and performance of the reinforced structure.

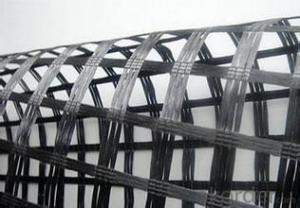

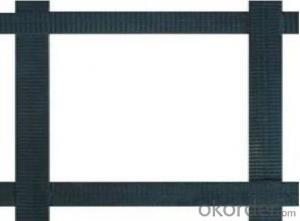

- Classification of plastic geogrid

- First, what is a one-way plastic geogrid: one-way plastic geogrid is a high density polyethylene (HDPE) as raw material, through the extrusion press into a thin plate and then the rules of the hole network, and then the longitudinal tensile geogrid.Two, what are the characteristics of one-way plastic geogrid:1, the polymer into a linear state and the formation of a uniform distribution, high strength of the node of the long elliptical mesh integral structure. This kind of structure has high tensile strength and rigidity, and it provides the ideal chain system of bearing and diffusion of soil.

- How many steel wire two-way steel plastic geogrid tensile strength reached 100kn/m

- If the wire is thick, the wire is less,There's a formulaDon't ask me

- Yes, geogrids are suitable for reinforcing railway ballasts. Geogrids provide effective soil reinforcement and stabilization, enhancing the load-bearing capacity and overall performance of railway ballasts. They help distribute loads more evenly, reduce settlement and deformation, and improve the long-term stability of the ballast layer. Geogrids also help prevent lateral spreading of the ballast material, maintaining track alignment and reducing maintenance requirements. Overall, geogrids are a reliable and effective solution for reinforcing railway ballasts.

- What are the geogrid testing items

- Appearance identification. Material overlap. There is no fixed smooth wrinkles, loose

- Yes, geogrids can be used in underground mining applications. Geogrids are commonly used for reinforcement and stabilization purposes in mining operations, specifically in the construction of underground tunnels, shafts, and walls. They provide support to the surrounding soil or rock, enhance stability, and help prevent deformation and collapse. Geogrids are particularly useful in underground mining environments as they are resistant to chemical and biological degradation, have high tensile strength, and can withstand heavy loads.

- Yes, geogrids can be effectively used in soil stabilization for erosion control. Geogrids are synthetic materials that are commonly placed within the soil to enhance its stability and prevent erosion. They provide reinforcement and structural support to the soil, reducing its susceptibility to erosion caused by water or wind. By improving the soil's strength and preventing movement, geogrids help to stabilize slopes, embankments, and other areas prone to erosion, making them an ideal solution for erosion control in soil stabilization projects.

- Yes, geogrids can be used in the reinforcement of bridge approach embankments over soft soils. Geogrids are commonly employed in such applications to enhance the stability and strength of the embankment by distributing the loads and reducing settlement. They provide additional tensile strength and improve the overall performance of the embankment, making it a suitable solution for addressing the challenges posed by soft soils in bridge approach embankments.