Tensar Geogrid Calculator

Tensar Geogrid Calculator Related Searches

Geogrid Machine Geogrid Plastic Paver Plastic Geogrid Black Poly Geogrid Geogrid Landscape Fabric Geogrid Fabric Driveway Geogrid Cost Per Square Foot Geogrid Grass Driveway Geogrid Grass Geogrid RollHot Searches

Fiberglass Scaffolding For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale Geogrid Fabric For Sale Gas Powered Core Aerator For Sale Revolution 4 Propeller For Sale Alabaster Carving Stone For Sale Geogrid For Sale Near Me Tensar Geogrid For Sale Geogrid For Sale Ex Display Log Cabins For Sale Photoelectric Cells For Sale Athletic Lockers For Sale Cubicle Partitions For Sale Stearman Propeller For Sale Palram Greenhouses For Sale Gumbo Bowls For Sale Suzuki Propellers For Sale Freight Crates For Sale Outhouse Sheds For SaleTensar Geogrid Calculator Supplier & Manufacturer from China

Okorder.com is a professional Tensar Geogrid Calculator supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Tensar Geogrid Calculator firm in China.Hot Products

FAQ

- Geogrids improve the stability of channel linings by providing reinforcement and confinement to the soil or aggregate materials used in their construction. The geogrids act as a reinforcement element by distributing the tensile forces within the soil or aggregate, preventing excessive deformation and maintaining the integrity of the channel lining. Additionally, geogrids restrict lateral movement of the soil or aggregate, thereby enhancing the overall stability and preventing erosion or failure of the channel lining.

- The recommended depth of geogrid installation can vary depending on the specific project and soil conditions. However, in general, it is recommended to install geogrids at a depth of at least 12 inches to provide adequate stabilization and reinforcement to the soil.

- There are several factors that can affect the cost-effectiveness of geogrid-reinforced structures. Firstly, the type and quality of the geogrid material used can significantly impact the overall cost. Higher-quality geogrids may initially be more expensive but offer better long-term performance, potentially reducing maintenance and repair costs over time. Additionally, the design and engineering of the structure play a crucial role. Properly designed geogrid-reinforced structures can optimize material usage and minimize construction costs. The expertise and experience of the engineers and contractors involved also contribute to the cost-effectiveness, as their knowledge can help avoid unnecessary expenses and ensure efficient construction. The specific site conditions, such as soil characteristics and slope stability, are also important factors. Geogrids are typically used to enhance soil stability, so the suitability of the soil for reinforcement and the extent of reinforcement required can impact costs. Difficult terrain, challenging access, or the need for additional site preparation can also increase costs. Lastly, the lifespan and durability of geogrid-reinforced structures should be considered. While geogrids are designed to be long-lasting, factors like environmental conditions, loading requirements, and proper installation can affect their performance. Investing in high-quality materials and proper installation methods may initially increase costs but can result in longer service life and reduced maintenance expenses in the long run.

- The benefits of using geogrids in roadways are numerous. Firstly, geogrids provide reinforcement to the road surface, increasing its strength and stability. This helps in preventing the formation of cracks and potholes, leading to longer-lasting and more durable roads. Secondly, geogrids help in distributing the load from vehicular traffic more evenly, reducing the stress on the road and preventing premature deterioration. Additionally, geogrids improve the overall performance of the road by enhancing its resistance to rutting, erosion, and other forms of pavement distress. Moreover, geogrids can reduce construction costs by reducing the amount of aggregate required for road construction. Overall, the use of geogrids in roadways improves their longevity, reduces maintenance needs, and enhances the safety and comfort of road users.

- Geogrids improve the stability of cut slopes by reinforcing the soil and preventing erosion. When placed within the soil, geogrids provide tensile strength and distribute the forces acting on the slope, reducing the risk of slope failure. They also enhance the overall stability by increasing the shear strength of the soil, minimizing displacement and potential sliding. Additionally, geogrids help to control water infiltration, reducing pore pressure and preventing saturation, which can further compromise the stability of cut slopes.

- Geogrids offer several advantages in civil engineering and construction projects. Firstly, they enhance soil stability and reinforce weak soils, preventing soil erosion and improving load-bearing capacity. Secondly, geogrids can reduce construction costs by allowing for the use of locally available and lower-quality materials instead of expensive fill materials. Additionally, they provide long-term durability, resistance to chemical degradation, and high tensile strength, ensuring the longevity and structural integrity of the project. Moreover, geogrids are easy to install, lightweight, and flexible, making them convenient for various applications and reducing labor requirements. Overall, using geogrids results in improved soil performance, cost-effectiveness, and efficient construction processes.

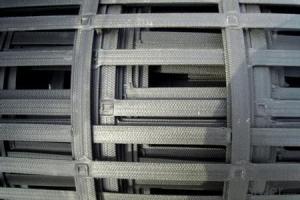

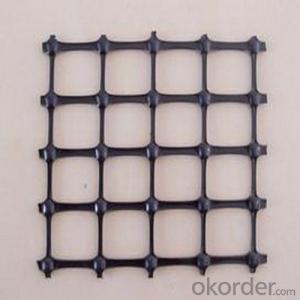

- Geogrids are connected to the surrounding soil through a process called interlocking. The geogrids have open spaces or apertures that allow soil particles to fill in, creating a bond between the geogrid and the soil. This connection helps improve the stability and load-bearing capacity of the soil, making it more resistant to erosion and preventing the geogrid from slipping or moving out of position.

- The effect of installation spacing on geogrid behavior is that it can impact the overall performance and effectiveness of the geogrid. Proper installation spacing ensures proper load distribution and reinforcement, allowing the geogrid to effectively stabilize the soil and prevent deformation or failure. Inadequate spacing can lead to localized stress concentrations, reduced load capacity, and potential geogrid failure. Therefore, the spacing between geogrid installations is an important factor to consider in order to achieve optimal performance and long-term stability.