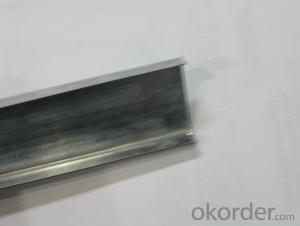

Stock Aluminum Profiles

Stock Aluminum Profiles Related Searches

Best Paint For Stainless Steel Paint For Galvanized Steel Steel Frames For Furniture Self Tapping Screws For Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For Bbq Step Bit For Stainless Steel Sponge For Stainless SteelHot Searches

Galvanized Steel Scrap Price Galvanized Steel Prices Stone Wall Tiles Cost Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Used Solar Inverter For Sale Portable Led Signs For Sale Stone Hot Water Bottles For SaleStock Aluminum Profiles Supplier & Manufacturer from China

Okorder.com is a professional Stock Aluminum Profiles supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Stock Aluminum Profiles firm in China.Hot Products

FAQ

- Absolutely! Food packaging systems can definitely utilize aluminum pipes. The food industry widely employs aluminum pipes for packaging a variety of food products because of their exceptional qualities. To begin with, the lightweight nature of aluminum makes it highly convenient for packaging purposes. This feature allows for easy transportation and handling of food products, ultimately reducing shipping costs. Additionally, aluminum pipes possess robustness and durability, providing protection to the packaged food throughout storage and transportation. Moreover, aluminum is not only non-toxic but also non-reactive, ensuring food safety when used for packaging. It does not release any detrimental substances that could contaminate the food, thus preserving the integrity and quality of the packaged products. Furthermore, aluminum pipes exhibit remarkable barrier properties, safeguarding the food from moisture, light, and oxygen, which may lead to spoilage and degradation. Furthermore, aluminum is an extremely recyclable material, making it an environmentally friendly choice for food packaging systems. It can be effortlessly recycled and reused without compromising its properties, thereby reducing the environmental impact caused by packaging waste. To sum up, aluminum pipes are an ideal option for food packaging systems due to their lightweight nature, strength, non-toxicity, barrier properties, and recyclability. They offer an effective and safe packaging solution for various food products, ensuring freshness, quality, and longevity.

- Is the Haier refrigerator a copper tube or an aluminum tube?

- The iron pipe evaporator is better than the aluminum tube, perforated, easy to fill!

- Aluminum pipes are known for their excellent ability to handle vibration and shock loads. This is primarily due to their inherent characteristics and properties. Aluminum is a lightweight and highly ductile metal, which means it has the ability to deform under stress without breaking. This flexibility allows aluminum pipes to absorb and dissipate vibrations and shocks, preventing them from being transmitted to other parts of the system. Additionally, aluminum has a high strength-to-weight ratio, making it a strong and durable material. This strength enables aluminum pipes to withstand high impact forces and sudden shocks without deforming or failing. The resilience of aluminum pipes makes them a suitable choice for applications where vibration and shock loads are expected, such as in automotive and aerospace industries. Moreover, aluminum has excellent corrosion resistance properties, making it suitable for use in various environments. Corrosion can weaken pipes and make them more susceptible to failure under vibration and shock loads. However, aluminum's resistance to corrosion ensures that the pipes remain structurally sound and capable of handling such loads over a prolonged period. In conclusion, aluminum pipes are well-equipped to handle vibration and shock loads due to their lightweight, ductile nature, high strength-to-weight ratio, and corrosion resistance properties. These qualities make aluminum pipes a reliable choice for applications where these loads are a concern, providing durability and longevity to the systems they are used in.

- Yes, aluminum pipes are suitable for paper mills. Aluminum is highly resistant to corrosion and can withstand the harsh chemicals and high temperatures often found in paper mills. Additionally, aluminum pipes are lightweight, making them easy to install and maintain in the industrial setting of paper mills.

- The pressure ratings of aluminum pipes differ based on their dimensions and thickness. Typically, aluminum pipes can be rated from 150 psi to 500 psi. Nevertheless, it is crucial to acknowledge that these ratings may change depending on the specific usage and adherence to industry norms. Consequently, consulting the manufacturer or referring to applicable codes and standards is imperative in order to ascertain the precise pressure rating for a given aluminum pipe.

- I do not know compared with copper tube, durable, long time will appear trachoma?

- So we need to use it properly:Do not strike or defrost with sharp or hard material to prevent damage.Not special circumstances, long-term use of the refrigerator, because it is covered with a layer of ice can be isolated from the air to prevent oxidation.Put the refrigerator in a dry and airy place.

- In cold climates, aluminum pipes should have insulation with a minimum R-value of 6 to prevent heat loss and condensation. The insulation should be properly installed and sealed to ensure maximum efficiency and protection against freezing temperatures.

- Why magnetic ball and ball falls into the hollow tube, a magnetic ball fell to the ground slowly

- Aluminum is a conductor, magnet is equivalent to the magnetic field, that is, the ring conductor in the magnetic field to do cutting magnetic induction line, moving conductor induction electromotive force, and then produce electric field, thereby hindering the magnetic field changes, so that small ball movement slow! The concept of the place may have actual meaning should be in place please understand!