Stainless Steel Wire Singapore

Stainless Steel Wire Singapore Related Searches

Best Paint For Stainless Steel Blanket Insulation For Steel Buildings Primer For Galvanized Steel Foam Filter For Stainless Steel H S Code For Stainless Steel Surface Grinding Wheels For Stainless Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For BbqHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Used Solar Inverter For Sale Steel Mesh Panels For SaleStainless Steel Wire Singapore Supplier & Manufacturer from China

Okorder.com is a professional Stainless Steel Wire Singapore supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Stainless Steel Wire Singapore firm in China.Hot Products

FAQ

- Anti loosening of stainless steel screw

- Once encountered a customer, the company needs stainless steel screws need to be loose. Simply speaking, it is to make the stainless steel screws used in the product material, can make stainless steel screws will not light fall. Screws are required to be fastened together with the product material more tightly. There are two solutions for stainless steel screw looseness prevention. Next, present the following two solutions to prevent the looseness of stainless steel standard parts.

- The cost of stainless steel wire tends to be higher compared to other materials due to its durability, corrosion resistance, and high-quality properties. However, it is essential to consider the specific application and requirements when assessing the overall value and cost-effectiveness of stainless steel wire compared to alternative materials.

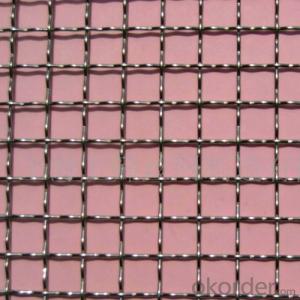

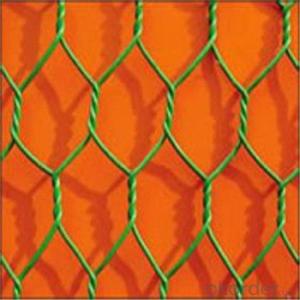

- Yes, stainless steel wire can be used for netting. It is a durable and corrosion-resistant material, making it suitable for various applications such as fencing, fishing nets, safety barriers, and other forms of netting.

- 443 short silk hairline stainless steel 443 what does that mean?

- 443 stainless steel is a ferritic stainless steel is now generally used to replace 304, rust resistance and processing performance and is 304, the comprehensive promotion in electrical appliances, utensils, kitchen equipment, elevator, oven manufacture etc..

- What stainless steel screws are best?

- Stainless steel screw material is generally A2-70, and if the ocean and other special corrosive environment, you have to change to 316L;Building is mainly to ask what type of screw, then this still needs reference working conditions and installation conditions

- Yes, stainless steel wire can be used for making wire hangers. It is a durable and corrosion-resistant material that provides strength and longevity to the hangers.

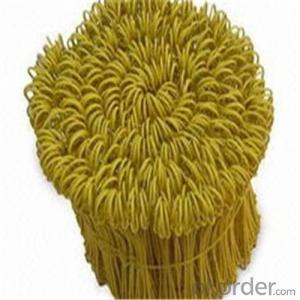

- Certainly, coils are a readily available option for supplying stainless steel wire. They are widely used for packaging this type of wire due to their convenience in terms of handling, storage, and transportation. Typically, the wire is tightly wound into a circular shape, resulting in a compact coil that can be customized according to customer specifications. To ensure stability and prevent unraveling during shipping or storage, the coils are commonly secured with straps or bands. This packaging technique guarantees the wire's organization and protection, making it suitable for various applications including welding, construction, and manufacturing.