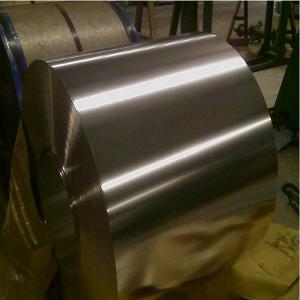

Spte Tinplate

Spte Tinplate Related Searches

Printing Tinplate Sheet Tinplate Iron Packaging Tape Tinplate Material Tinplate Cover Standard Gauge Tinplate Tinplate Tea Set Mth Tinplate Set Circle Packaging Machinery Inc Tinplate Model TrainsHot Searches

Price Of Tinplate Tinplate Sheet Price Tinplate Price Per Ton Tinplate Stock Price Tata Tinplate Price List Tinplate Price Trend Tinplate Nse Share Price Tinplate Price Chart Tinplate Share Price Nse Tata Tinplate Share Price Tinplate Share Price Today Tinplate Share Price Bse Tinplate Price Tinplate Share Price Tinplate Cans Manufacturers Tinplate China Tinplate Stock Price Tata Tinplate Price List Tinplate Price Trend Tinplate Nse Share PriceSpte Tinplate Supplier & Manufacturer from China

Okorder.com is a professional Spte Tinplate supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Spte Tinplate firm in China.Hot Products

FAQ

- Common sizes and shapes of tinplate containers include round cans, rectangular tins, and square boxes. The sizes of these containers can vary, but some standard sizes include 8-ounce, 16-ounce, and 32-ounce cans.

- Yes, tinplate can be used for industrial containers. Tinplate is a type of steel sheet coated with a thin layer of tin, which provides corrosion resistance and durability. It is commonly used for manufacturing various types of containers, including those used in the food and beverage industry, aerosol cans, and paint cans.

- The main difference between tinplate and tinplate laminates in terms of product visibility is that tinplate laminates have a transparent layer of plastic or other materials on top of the tinplate, allowing for a clear view of the product inside the packaging. In contrast, tinplate alone does not provide this visibility as it is a solid metal material.

- Yes, tinplate can be used for consumer electronics packaging. Tinplate is a durable material that provides excellent protection against moisture, corrosion, and physical damage. It is commonly used for packaging various consumer electronics such as mobile phones, tablets, and small appliances. Additionally, tinplate can also be easily printed on, allowing for attractive and customizable packaging designs.

- Tinplate is coated with organic coatings through a process called coil coating. In this process, the tinplate is cleaned and pre-treated to ensure proper adhesion of the coating. Then, a thin layer of organic coating is applied onto the surface of the tinplate using various methods such as roller coating or spraying. The coated tinplate is then cured at high temperatures to ensure the coating adheres firmly. This organic coating provides protection against corrosion and enhances the appearance of the tinplate.

- The common industry standards for tinplate include specifications for the tin coating weight, the base metal thickness, surface finish, and the adhesion of the tin coating. These standards ensure consistency and quality in the production of tinplate, allowing for its effective use in various industries such as packaging, automotive, and construction.

- Tinplate generally has low resistance to UV radiation as it is not naturally UV-resistant. However, the addition of protective coatings or finishes can enhance its UV resistance to some extent.

- Tinplate can be affected by different types of cosmetics due to their chemical composition. Certain cosmetics, such as those containing acidic or alkaline ingredients, can cause corrosion or discoloration on the tinplate surface. Additionally, prolonged exposure to certain cosmetics, especially those containing solvents or oils, can lead to the degradation of the protective coating on the tinplate, making it more susceptible to rusting. Therefore, it is important to choose cosmetics that are compatible with tinplate packaging to ensure its longevity and integrity.