Sheet Metal 20 Gauge

Sheet Metal 20 Gauge Related Searches

Cut Off Wheels For Metal Grinding Wheels For Metal Track Lighting For Walls Track Lighting With Plug Metal Stainless Steel Stainless Steel Nose Stud Industrial Led Track Lighting 24 Gauge Galvanized Sheet Metal 28 Gauge Galvanized Sheet Metal 4X8 Galvanized Sheet MetalHot Searches

Used Metal Folding Chairs For Sale Large Metal Containers For Sale Metal Shop Cabinets For Sale Metal Shipping Crates For Sale Galvanized Steel Scrap Price Fiber Sheet Price In India Galvanized Steel Prices Plastic Fiber Sheet Price Upvc Roofing Sheet Manufacturer In India China Geomembrane Roll Sheet Lasani Wood Sheet Price Rhino Roofing Sheet Price List Tinplate Sheet Price Mdf Price Per Sheet 4Mm Mdf Sheet 1220X2440Mm Price Grp Sheet Price Aluminum Sheet Stock Sizes Cost Of 4X8 Sheet Of Plywood Cost Of Drywall Per Sheet Buy Sheet PlasticSheet Metal 20 Gauge Supplier & Manufacturer from China

Okorder.com is a professional Sheet Metal 20 Gauge supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Sheet Metal 20 Gauge firm in China.Hot Products

FAQ

- The average lifespan of painted steel sheets can vary depending on various factors such as the quality of the paint, the environment in which the sheets are used, and the level of maintenance they receive. However, in general, painted steel sheets can have a lifespan of 15 to 25 years. This estimate assumes that the sheets are properly installed, regularly inspected for damage or corrosion, and receive any necessary touch-up or maintenance work as needed. It is important to note that factors such as exposure to harsh weather conditions, chemical exposure, and physical damage can significantly impact the lifespan of painted steel sheets. Regular maintenance and proper care can help extend the lifespan of painted steel sheets beyond the average range.

- Certainly, skylights or roof windows can make use of steel sheets. Steel, being a resilient and robust substance, is capable of enduring diverse weather circumstances, thus rendering it appropriate for such purposes. Moreover, steel sheets may be crafted and tailored to satisfy the particular specifications of skylights or roof windows. By installing them, one can avail oneself of both natural light and ventilation while simultaneously upholding the building's structural integrity. However, it is vital to guarantee adequate insulation and glazing in order to avert any heat loss or gain and to maximize energy efficiency.

- Yes, steel sheets are suitable for railway carriages. Steel is a popular material choice for railway carriages due to its strength, durability, and ability to withstand the constant wear and tear associated with train operations. Steel sheets provide the necessary structural integrity to support the carriage and its passengers, while also offering protection against impacts and extreme weather conditions. Additionally, steel is relatively cost-effective and readily available, making it an ideal choice for the construction of railway carriages.

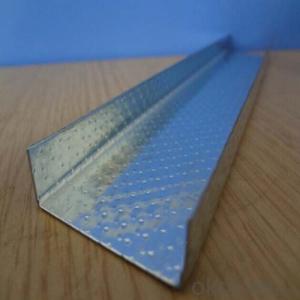

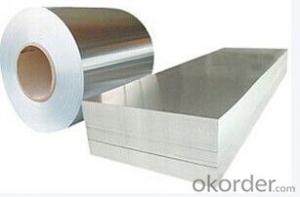

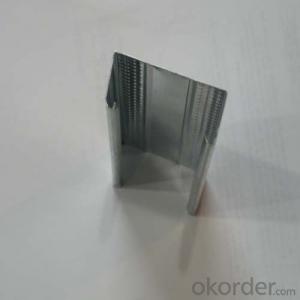

- There are several different types of steel sheet finishes that serve various purposes and provide different aesthetics. Some of the common types include: 1. Hot Rolled: This finish is achieved by heating the steel sheet above its recrystallization temperature and then rolling it to the desired thickness. It has a rough and textured surface, making it suitable for applications where appearance is not a priority. 2. Cold Rolled: After the hot rolling process, the steel sheet is passed through rollers at room temperature to achieve a smooth and polished finish. Cold rolled finishes are often used in applications that require a superior surface finish, such as automotive panels or appliances. 3. Galvanized: In this process, the steel sheet is coated with a layer of zinc to provide corrosion resistance. The zinc coating also gives the sheet a shiny and reflective appearance. Galvanized finishes are commonly used in outdoor applications to protect against rust and harsh weather conditions. 4. Stainless Steel: This finish is achieved by adding chromium to the steel sheet, which provides excellent corrosion resistance and a sleek, reflective surface. Stainless steel finishes are widely used in kitchen appliances, architectural applications, and medical equipment, where hygiene and durability are essential. 5. Coated Finishes: Steel sheets can be coated with various materials, such as paint, epoxy, or polymer, to enhance their appearance or provide additional protection. Coated finishes can be customized to meet specific requirements, such as color or texture, and are often used in architectural and decorative applications. 6. Brushed: This finish is obtained by brushing the steel sheet with abrasive material, creating a textured and matte surface. Brushed finishes are commonly used in interior design and furniture manufacturing, where a contemporary and stylish appearance is desired. These are just a few examples of the different types of steel sheet finishes available. The choice of finish depends on the specific requirements of the application, such as corrosion resistance, aesthetic appeal, or surface texture.

- Yes, steel sheets are suitable for railway or transportation infrastructure. Steel is a durable and strong material that can withstand heavy loads and provide stability to railway tracks and transportation structures. It is commonly used in the construction of bridges, tunnels, and rail lines due to its high strength-to-weight ratio and resistance to corrosion. Additionally, steel sheets can be easily fabricated and installed, making them a practical choice for such infrastructure projects.

- The average lifespan of steel sheets used for roofing can vary depending on several factors. However, high-quality steel roofing sheets are designed to be extremely durable and long-lasting. On average, these steel sheets can last anywhere between 40 to 70 years or even longer with proper maintenance and care. Factors such as the type and thickness of the steel, the quality of the coating or finish, the climate and weather conditions in the area, and the level of maintenance can all affect the lifespan of steel roofing sheets. Regular inspections, cleaning, and repairs when needed can help prolong the lifespan of the steel sheets and ensure they remain in good condition for many years. It is always advisable to consult with roofing professionals or manufacturers for specific guidelines and recommendations regarding the lifespan of steel sheets used for roofing in a particular context.

- Steel sheets have several advantageous properties, including high strength and durability, excellent corrosion resistance, good thermal conductivity, and the ability to be easily formed and welded.

- Thickness of steel sheets is commonly determined using either a gauge or caliper. The gauge system, which assigns a numerical value to represent thickness, is the most widely used method. In this system, a higher gauge number indicates a thinner sheet. For instance, a 14-gauge steel sheet is thicker than a 20-gauge sheet. To measure thickness with a gauge, a tool called a sheet metal gauge is employed. It comprises notches or slots that correspond to specific gauge numbers. By placing the gauge against the edge of the steel sheet, the appropriate slot indicates its thickness. Alternatively, a caliper can be utilized to measure steel sheet thickness. This precision instrument has two adjustable jaws to accurately measure the distance between them. When measuring a steel sheet's thickness with a caliper, the jaws are gently closed around the sheet, and the measurement is obtained from the caliper's display. Both the gauge and caliper methods offer precise measurements of steel sheet thickness, facilitating manufacturers, engineers, and other professionals in selecting the suitable sheet for their specific applications.