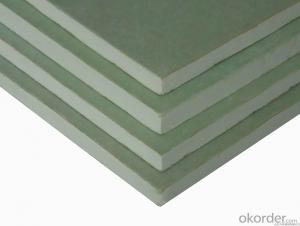

Recycle Particle Board

Recycle Particle Board Related Searches

Fiber Sheet For Roof Waterproofing Additive For Cement Render Stainless Steel Hot Tubs Stainless Steel Draining Board Aluminum Foil Hot Rail Hot Aluminum Foil Trick Pig Hot Water Bottle Cover Tartan Hot Water Bottle Cover Electric Hot Water Bottle Argos Funny Hot Water Bottle CoversHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Stainless Steel Tank For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Used Solar Inverter For Sale Portable Led Signs For Sale Stone Hot Water Bottles For Sale Aluminum Coil Stock For Sale Used Foam Board Insulation For SaleRecycle Particle Board Supplier & Manufacturer from China

Okorder.com is a professional Recycle Particle Board supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Recycle Particle Board firm in China.Hot Products

FAQ

- Particleboard production process requires proper hot pressing pressure

- Molding technology refers to the operation of a product that forms a product. There are three kinds of mature technology.

- Make the raw material of the particleboard

- Can be pre-pressure and hot-pressing treatment. Preload pressure of 0.2 to 2 MPa, with a flat press or roller press.

- Particleboard production requires proper moisture content

- appropriate pressure time. The time is too short, the middle resin can not be fully cured, the finished product in the thickness of the elastic recovery increased,

- According to the surface conditions:

- According to the slab structure of single layer, three (including multi-layer), gradient three kinds of structure.

- What is the modeling technology department?

- mainly urea-formaldehyde resin, the product surface with a single board or resin impregnated paper paste, a molding.

- How does the particleboard work?

- Hot pressing is a key step in the production of particleboard, which acts to cure the slab in the slab and consolidate the loose slab into a sheet of the specified thickness

- What are the raw materials for making the particleboard?

- such as linen (shavings) board, bagasse (shavings) plate. Adhesive multi-purpose urea-formaldehyde resin and phenolic resi

- What is the production process of particleboard

- it is beneficial to improve the bending strength, tensile strength and surface finish, and reduce the possibility of slag stratification in the relief.