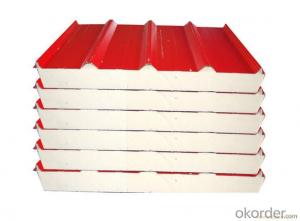

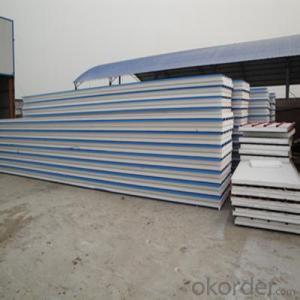

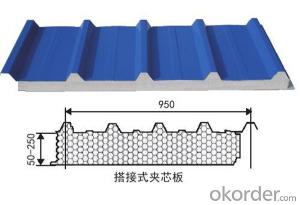

Polystyrene Roof Panels

Polystyrene Roof Panels Related Searches

Best Inverter For Solar Panels Inverter Box For Solar Panels Inverter For Solar Panels Cost Fiberglass Panels For Roofing Foam Panels For Building Wall Lights For Bedrooms Geogrid For Retaining Wall Tar Paper For Roofing Wall Spotlight With Plug Woven Steel Mesh PanelsHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Tank For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Used Solar Inverter For Sale Portable Led Signs For Sale Steel Mesh Panels For SalePolystyrene Roof Panels Supplier & Manufacturer from China

Okorder.com is a professional Polystyrene Roof Panels supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Polystyrene Roof Panels firm in China.Hot Products

FAQ

- Certainly, architectural or decorative applications can indeed make use of steel sheets. Steel, as a material, is known for its versatility and durability, providing numerous advantages for both structural and aesthetic purposes. In terms of architecture, steel sheets can serve purposes like roofing, wall cladding, and structural framing, ensuring strength, stability, and resilience against harsh weather conditions. Moreover, architects and designers can fashion steel sheets into various shapes, sizes, and finishes, enabling them to create distinctive and visually appealing structures. When it comes to decoration, steel sheets can be employed for interior and exterior design elements, such as decorative panels, screens, railings, and sculptures. The opportunity to personalize steel sheets with diverse patterns, textures, and colors makes them a popular choice for enhancing the visual allure of buildings and spaces. All in all, steel sheets are an adaptable material suitable for a wide range of architectural and decorative uses, offering both functionality and aesthetics.

- Steel sheets are highly malleable and can handle bending or flexing quite well. Due to their inherent strength and ductility, steel sheets can be easily bent or flexed without breaking or cracking, making them ideal for various applications in construction, manufacturing, and engineering industries.

- Yes, steel sheets can be easily cut using various tools such as shears, plasma cutters, or laser cutters.

- The purpose of steel sheets is to provide a durable and versatile material that can be used in various applications such as construction, automotive manufacturing, and fabrication. They are known for their strength, resistance to corrosion, and ability to be formed into different shapes, making them an essential component in many industries.

- A hot rolled steel sheet is made by rolling a heated slab of steel through a series of large rollers, resulting in a thick and rough surface finish. On the other hand, a pickled steel sheet undergoes an additional process called pickling, where the surface of the hot rolled steel is treated with an acid solution to remove impurities and create a smooth and clean surface finish. So, the main difference between the two is the surface finish - hot rolled steel has a rougher surface, while pickled steel has a smoother and cleaner surface.

- Yes, steel sheets are suitable for building envelopes or curtain walls. Steel offers excellent strength and durability, making it a reliable choice for construction projects. It can withstand harsh weather conditions and provide a secure barrier against external elements. Additionally, steel sheets can be easily manipulated to create various architectural designs, allowing for flexibility and creativity in building envelope and curtain wall designs.

- The cost of steel sheets can differ based on various factors, including the steel's type and grade, the sheet's thickness and size, and the prevailing market conditions. Typically, steel sheets can be priced between $0.60 and $1.50 per pound. Nevertheless, it is crucial to note that these figures are only approximate and subject to frequent modifications due to fluctuations in the steel market and other economic elements. To obtain the most precise and current pricing details for steel sheets, it is recommended to consult local suppliers or utilize online platforms.