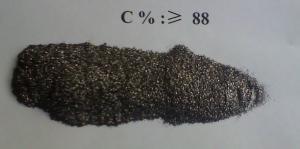

Natural Flake Graphite

Natural Flake Graphite Related Searches

Carbon Graphite BlockHot Searches

Natural Flake Graphite Supplier & Manufacturer from China

Okorder.com is a professional Natural Flake Graphite supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Natural Flake Graphite firm in China.Hot Products

FAQ

- Why is the battery electrolyte more potassium hydroxide and sodium hydroxide is less used?

- The solution of potassium hydroxide at a density of 1.25~1.27 (15 DEG C) is used at temperatures below -15. For the purpose of taking into account the low temperature performance and the charge holding capacity, the sealed nickel cadmium battery adopts an aqueous solution of potassium hydroxide with a density of 1.40 (15 DEG C). In order to increase the capacity and cycle life of battery, usually adding lithium hydroxide amount in the electrolyte (per litre of electrolyte and 15~20g).

- The difference between silicone and silicone?

- Silica gel and grease are helpful to system cooling material, the difference is that the silica gel with good thermal performance and insulation, and will not lose its stickiness pale yellow translucent glue at higher temperatures, mainly used in the surface of the heat radiating sheet sticking device; and the grease is not sticky, is a liquid emulsion or cream like, its role is to fill the gap between the chip and the heat sink, improve the efficiency of heat conduction.

- Is oxygen allowed in the oxygen pipe?

- The so-called oxygen pipeline, which depends on the medical or edible, or industrial oxygen pipeline. If it is industrial, a little graphite is possible, but the proportion can not be too large

- What are the hazards of inhalation of graphite dust?

- It must be harmful to human beings! Look at the dictionary of carbon black dust lung disease Description: black carbon pneumoconiosis: long-term inhalation of carbon black dust caused by pneumoconiosis. Carbon black is mainly the quality of easy flying carbon. Although the production has been closed and automated, the phenomenon of dust flying still exists. Therefore, workers who produce and use carbon black may have black carbon pneumoconiosis, the shortest length of onset is 15 years, the longest can be more than 25 years, the clinical symptoms are mild, and the progress is slow, and generally does not affect the ability to work.

- Which shipping company can pick up the name of graphite? Graphite products are mainly exported to India, Italy and the United states!

- The packing of graphite powder is usually ton bag and mother bag.The packing of the graphite blocks is usually packed in wooden cases, which will not pollute the hull. Our company is out of date and there is no shipping company saying it can not be answered.

- What graphite powder made of graphite products, high hardness?! Wear-resisting! Good moisture! It can be made into graphite products at 100-200 degrees high temperature

- Graphite powder is divided into natural graphite powder and artificial graphite powder, graphite powder made of graphite products, you need to add binders, binders useful for a variety of resins, asphalt and so on.

- How to deal with graphite powder? Anyone recycle it?

- Graphite powder is an important industrial raw material, there is a recovery, but the graphite powder you said should be a waste in the production of surplus, quality is better than before, but the graphite powder prices, some specialized recycling of the graphite powder, graphite powder is not a professional manufacturer of recycling, is the original mineral for graphite the raw material, want to help to you, hope to adopt, thank you.

- Know how the colloidal graphite powder comes in

- There are two ways to make colloidal graphite: (1) mechanical method. Natural graphite is crushed and treated with hydrochloric acid and hydrofluoric acid to remove impurities. Added to the aqueous solution of tannic acid, which is repeatedly inverted into paste. Colloidal graphite can be obtained by adding a certain proportion of water and ammonia, and then by ultrasonic treatment to further reduce the particle size. (2) chemical method. After being purified and crushed, the natural graphite is added with concentrated nitric acid and concentrated sulfuric acid and water at 90 DEG C, and then obtained by cleaning, drying, adding water, ethanol, acetone and other dispersing agents to obtain colloidal graphite. Add stabilizer such as sodium oleate, sulfate and so on, so that graphite particles do not agglomerate. Ammonia transfers the graphite colloid to the gum solution and regulates the pH value.