Mirafi 5xt Geogrid

Mirafi 5xt Geogrid Related Searches

Fridge With Freezer On Bottom Driveway Pillars With Lights Blu Ray Player With Recorder Blu Ray Player With Internet Geogrid In Retaining Walls 1708 Biaxial Fiberglass Tape Pullout Resistance Of Geogrid Geogrid Warp Knitting Machine Srw 3 Series Geogrid Biaxial Plastic GeogridHot Searches

Fiberglass Scaffolding For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale Geogrid Fabric For Sale Gas Powered Core Aerator For Sale Revolution 4 Propeller For Sale Alabaster Carving Stone For Sale Geogrid For Sale Near Me Tensar Geogrid For Sale Geogrid For Sale Ex Display Log Cabins For Sale Photoelectric Cells For Sale Athletic Lockers For Sale Cubicle Partitions For Sale Stearman Propeller For Sale Palram Greenhouses For Sale Gumbo Bowls For Sale Suzuki Propellers For Sale Freight Crates For Sale Outhouse Sheds For SaleMirafi 5xt Geogrid Supplier & Manufacturer from China

Okorder.com is a professional Mirafi 5xt Geogrid supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Mirafi 5xt Geogrid firm in China.Hot Products

FAQ

- Yes, geogrids can be used in temporary erosion control applications. Geogrids are often employed in these scenarios to stabilize soil and prevent erosion until more permanent erosion control measures can be implemented. They are effective in reinforcing and stabilizing the soil, reducing the likelihood of erosion, and providing temporary erosion control solutions.

- Yes, geogrids are generally resistant to freeze-thaw cycles. Their high tensile strength and flexibility allow them to withstand the expansion and contraction caused by freezing and thawing without significant damage. This makes geogrids an effective solution for stabilizing soil and preventing erosion in cold climates.

- Yes, geogrids are suitable for coastal engineering projects. They provide effective erosion control, stabilize slopes, and reinforce soil structures in coastal areas. Geogrids help to prevent soil erosion caused by waves, tides, and storm surges, making them an ideal solution for coastal protection and resilience.

- Yes, geogrids can be used in railway track bed stabilization. Geogrids are commonly used in geotechnical engineering applications to improve the stability and performance of soil structures. In railway track bed stabilization, geogrids can provide reinforcement and increase the load-bearing capacity of the track bed, reducing settlement and improving overall stability.

- Geogrids reinforce slopes by providing tensile strength and stability to the soil, preventing erosion and retaining the soil in place. They act as a reinforcement layer, distributing the applied loads and reducing the potential for slope failure.

- Geogrids help in slope stabilization by providing reinforcement and increasing the overall stability of the soil. They are installed in the slope to distribute the forces acting on the soil, preventing erosion, reducing soil movement, and minimizing the risk of landslides. The geogrids act as a barrier, preventing the soil from sliding down the slope, thereby enhancing its stability and longevity.

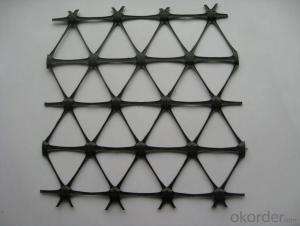

- A woven geogrid is made by weaving synthetic fibers together to create a strong and flexible grid structure. This type of geogrid has high tensile strength and is commonly used for soil stabilization and reinforcement. On the other hand, a non-woven geogrid is made by bonding synthetic fibers together without the use of weaving. It is typically a lower-cost option and is commonly used for filtration and separation applications. Overall, the main difference between the two is the manufacturing process and the intended use.

- Geogrids improve the performance of reinforced soil walls by providing additional strength and stability to the soil structure. They act as a reinforcement material, distributing the forces exerted on the wall more evenly and preventing the soil from sliding or collapsing. This results in increased load-bearing capacity, reduced settlement, and improved overall stability of the reinforced soil walls.