Geomembrane Pond Liner

Geomembrane Pond Liner Related Searches

Geomembrane For Ponds 30 Mil Pvc Geomembrane Pvc Geomembrane Institute Properties Of Geomembrane Plastic Geomembrane Geomembrane Material Geomembrane Fabric Harga Geomembrane Per Roll Geomembrane Roll Composite GeomembraneHot Searches

China Pvc Geomembrane China Geomembrane Roll Sheet Scaffolding Manufacturer In Mumbai Hdpe Geomembrane Sheet Price Hdpe Geomembrane China China Geomembrane Geomembrane China Hdpe Geomembrane Price Geomembrane Liner Price Geomembrane Price Black Plastic Plant Pots Wholesale Wholesale Hdpe Geomembrane Roll Geomembrane Factory Wholesale Liner Hdpe Geomembrane Spring Manufacturer Singapore Bistable Spring Manufacturer Wholesale Geomembrane Hdpe Wholesale Hdpe Geomembrane Geomembrane Market Size Geomembrane For SaleGeomembrane Pond Liner Supplier & Manufacturer from China

Okorder.com is a professional Geomembrane Pond Liner supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Geomembrane Pond Liner firm in China.Hot Products

FAQ

- Geomembranes are designed to handle wave action by providing a barrier that is resistant to the forces generated by waves. They are typically made of durable materials, such as high-density polyethylene or PVC, that can withstand the impact and pressure exerted by waves. The smooth surface of geomembranes helps to reduce the frictional forces generated by the waves, allowing them to easily glide over the surface. Additionally, geomembranes are often anchored or secured in place to prevent displacement or damage caused by wave action. Overall, geomembranes are engineered to effectively handle wave action and provide reliable protection for various applications such as coastal erosion control or containment of liquids.

- Geomembranes can contribute to groundwater recharge by acting as a barrier that prevents infiltration of surface contaminants and contaminants present in the soil, thus protecting the underlying groundwater from pollution and maintaining its quality. Additionally, geomembranes can be utilized as liners in reservoirs or ponds, preventing seepage and allowing for the storage and controlled release of water, which can ultimately enhance groundwater recharge.

- nan

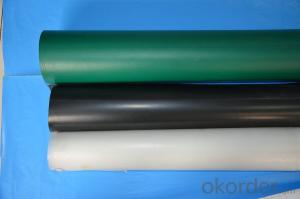

- Introduction of geomembrane Geomembrane can be divided into three categories: Geomembrane, reinforced geomembrane and composite geomembrane. Geomembrane density is not less than 9.0kg / m3, whose maximum elongation rate is not lower than 300%, frost resistance is not lower than -60 deg.] C, stability is not less than that of the 2% carbon black mixted in polyethylene. Reinforced geomembrane is reinforced in the film, reinforcement material is generally geotextile, nylon yarn cloth or canvas, which can be made into one cloth two membranes, two cloths three membranes, three cloths four membranes according to engineering requirements. Composite geomembrane is made by hot-pressing or binding with adhesives the membrane and acupuncture geotextile, which can be made into one cloth one membrane and two cloths one membrane according to engineering requirements. Geotextile prevents geomembrane from being punctured by contacted gravels, from being damaged by people and mechine when laying, and from damage during transportation; and at the same time it has dewatering effect, dewatering the infiltration water under membrane or pore water, accelerating consolidation of soft soil under membrane, and improving the friction coefficient of contact surface with the sandy gravel. So composite geomembrane is the optimal seepage-proof material for earth and rockfill dam.

- The role of geomembranes in saltwater containment is to provide a impermeable barrier that prevents the saltwater from leaking or seeping into the surrounding environment. They act as a protective lining or cover for saltwater containment structures such as ponds, reservoirs, or tanks, ensuring that the saltwater remains contained within the designated area.

- nan

- Benefits: hard wear anti dust and anti weathering corrosion resistance good curing light environmental protection? Can make concrete whole life longer, quality assurance 25 years: mixed pores of earth surfaces do carefully sealed, can prevent the invasion of oil pollution, and can prevent adhesion of tire India: surface dust more easily removed, with a stop the water penetration, alkalization, dustproof, advantages of weathering and erosion, and more convenient to use, no harm to the environment. Because of the permeability, so it can effectively maintain and develop concrete ground natural and soft and simple and convenient construction, after the construction of the ground without waxing, only water or occasionally mopping the floor with soap and water, will save a lot of repair and maintenance costs, a choice of permanent use

- Geomembranes prevent leakage by providing a barrier between the soil or liquid and the surrounding environment. They are impermeable and resistant to various substances, including chemicals, water, and gases. This prevents any potential leakage or seepage from occurring, ensuring containment and protection of the underlying materials or structures.

- nan

- it depends on the production process, and production companies may produce a shift of one batch, there are number of direct production contract for one batch. In engineering, 10000 square meters can be understood as one batch

- nan

- Forming characteristics: 1. It is an amorphous material with small moisture absorption and poor mobility. In order to improve the mobility and prevent the occurrence of bubbles, plastics may be dried in advance. Mold gating system should be thick and short, and the gate section should be large without blind angles. The mold need to be cooled, and coated chrome on the surface. 2. Due to the corrosion and mobility, it is best to use special equipment and mold. All products are required to be added to different types and amounts of additives. 3. It is easy to decompose, and will be more likely to decompose under temperature of 200 degrees and meets steeland copper. And corrosive and pungent gas will escape from it when composition. It has a small temperature range of forming. 4. When using the screw injection nozzle, the aperture should be large to prevent the material is lagged at dead corners. It is best that it has no inserts, and if it has, the inserted parts should be preheated.