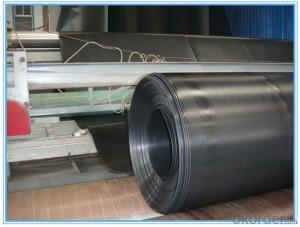

Geomembrane Hdpe

Geomembrane Hdpe Related Searches

Geomembrane For Landfill Geomembrane In Hdpe Geomembrane In Pakistan Pvc Geomembrane Liner Pvc Geomembrane Institute Hdpe Geomembrane Machine Basics Of Structural Engineering Hdpe Geomembrane Sheet Waterproof Geomembrane Geomembrane MaterialHot Searches

Geomembrane For Sale China Pvc Geomembrane China Geomembrane Roll Sheet Hdpe Geomembrane Sheet Price Hdpe Geomembrane China China Geomembrane Geomembrane China Hdpe Geomembrane Price Geomembrane Price Wholesale Hdpe Geomembrane Roll Geomembrane Factory Wholesale Liner Hdpe Geomembrane Wholesale Geomembrane Hdpe Wholesale Hdpe Geomembrane Geomembrane Market Size Wholesale Hdpe Geomembrana Wholesale Liner Geomembrane Geomembrane Liner Supplier Wholesale Geomembrane China Pvc GeomembraneGeomembrane Hdpe Supplier & Manufacturer from China

Okorder.com is a professional Geomembrane Hdpe supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Geomembrane Hdpe firm in China.Hot Products

FAQ

- Geomembranes play a crucial role in water treatment plant designs as they provide a reliable barrier to prevent contamination and leakage. They are used to line the various structures within the plant, such as ponds, tanks, and basins, ensuring that the treated water remains separate from the surrounding environment. Additionally, geomembranes help in the collection, storage, and containment of wastewater, facilitating its proper treatment and disposal.

- Yes, geomembranes can be considered environmentally friendly. They are designed to provide a barrier between hazardous substances and the environment, preventing contamination of soil and water. Additionally, geomembranes are often made of recyclable materials and can be reused or repurposed after their initial use, reducing waste generation. However, the overall environmental impact depends on factors such as the manufacturing process, disposal methods, and the specific application of the geomembrane.

- Geomembranes help in liquid containment by providing a flexible and impermeable barrier that prevents the liquid from leaking or seeping into the surrounding environment. They are designed to be resistant to chemicals, UV rays, and punctures, ensuring the integrity of the containment system. Additionally, geomembranes can be customized to fit specific project requirements, making them a reliable and versatile solution for various liquid containment applications.

- Yes, geomembranes can be used in mining operations. They are commonly used as liners for tailings ponds, heap leach pads, and other containment systems to prevent the escape of contaminants such as chemicals and waste materials into the surrounding environment. Geomembranes provide a barrier that helps protect soil, water sources, and ecosystems from the potentially harmful effects of mining activities.

- Geomembranes can contribute to the prevention of air pollution by acting as a barrier between potential sources of pollution, such as landfills or contaminated sites, and the surrounding environment. They prevent the release of harmful gases and pollutants into the air, ensuring that the air quality remains protected.

- Geomembranes prevent wastewater seepage in lagoons by acting as a barrier between the wastewater and the surrounding soil. They are impermeable liners made from materials such as high-density polyethylene (HDPE) or polyvinyl chloride (PVC) that are installed at the bottom and sides of lagoons. These liners effectively prevent the wastewater from infiltrating into the underlying soil and groundwater, minimizing the risk of contamination and protecting the environment.

- nan

- Geomembrane damage ratio field bottom damage lay and cover drainage gravel / sand protection reach up to 97% geomembrane defect wasteyard construction cost conventional quality assurance (CQA) program are more concerned about the welding quality the whole area of seepage-proof geomembrane conduct necessary detection table data and quote and analysis geomembrane construction quality assurance should focus on key impervious barrier leakage locations prospection and electrical leakage locations detection to ensure the quality of anti-seepage engineering is more efficient and more economical means

- nan

- Non-glued electrostatic membrane has three layers, just like a mobile phone film.Firstly,tear apart the first layer, stick it on the glass and then tear apart the surface film. Keep the middle layer, or only two layers, and tear apart one of them and stick. Then done.