Geogrid Tbl

Geogrid Tbl Related Searches

Fridge With Freezer On Bottom Driveway Pillars With Lights Blu Ray Player With Recorder Blu Ray Player With Internet Geogrid In Retaining Walls 1708 Biaxial Fiberglass Tape Pullout Resistance Of Geogrid Geogrid Warp Knitting Machine Srw 3 Series Geogrid Biaxial Plastic GeogridHot Searches

Fiberglass Scaffolding For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale Geogrid Fabric For Sale Gas Powered Core Aerator For Sale Revolution 4 Propeller For Sale Alabaster Carving Stone For Sale Geogrid For Sale Near Me Tensar Geogrid For Sale Geogrid For Sale Ex Display Log Cabins For Sale Photoelectric Cells For Sale Athletic Lockers For Sale Cubicle Partitions For Sale Stearman Propeller For Sale Palram Greenhouses For Sale Gumbo Bowls For Sale Suzuki Propellers For Sale Freight Crates For Sale Outhouse Sheds For SaleGeogrid Tbl Supplier & Manufacturer from China

Okorder.com is a professional Geogrid Tbl supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Geogrid Tbl firm in China.Hot Products

FAQ

- Yes, geogrids can be used in landfills. Geogrids are commonly used in landfill engineering as they provide reinforcement and stabilization to the landfill slopes and walls, preventing soil erosion and promoting the overall stability of the landfill structure.

- Yes, geogrids are effective in preventing soil erosion around pipelines. Geogrids provide stability and reinforcement to the soil, preventing it from eroding and protecting the pipelines from potential damage.

- Yes, geogrids can be used in retaining wall reinforcement systems. Geogrids are commonly used to improve the stability and strength of retaining walls by providing additional support and preventing soil erosion. They are typically placed within the soil layers of the retaining wall to enhance its structural integrity and prevent the movement of soil behind the wall.

- Geogrids and geopipes are both materials used in geotechnical and civil engineering applications, but they serve different purposes. Geogrids are typically made from high-strength polymers and are used to reinforce soils and provide stabilization. They have a grid-like structure with open spaces that allow soil to interlock with the grid, creating a stronger base. Geogrids are commonly used in retaining walls, road construction, and erosion control. On the other hand, geopipes are pipes made from various materials like plastic or concrete and are primarily used for drainage purposes. They have perforations or slots along their length, allowing water or gases to flow through. Geopipes are commonly used in subsurface drainage systems, stormwater management, and landfills to control water buildup and prevent soil saturation. In summary, the main difference between geogrids and geopipes lies in their function and structure. Geogrids provide soil reinforcement and stabilization, while geopipes facilitate drainage and water management.

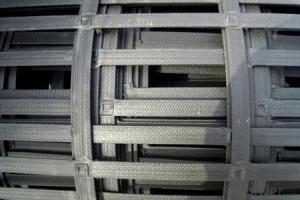

- Steel wire mesh is a kind of geotechnical material

- The wire grid contact strength (tensile, shear, tensile and torsional) must be high, and better grid vertical ribs contact force transmission performance, the transverse ribs have the force to the longitudinal rib through the contact, and vice versa. Therefore, requirements must contact the overall good contact strength to close rib strength (tensile fracture is not at the junction, or both) intensity should be small, in order to match, this is the most reasonable, the most economical. Otherwise, the contact strength is much lower than the reinforcement strength, cannot play the security capability of the high strength tensile ribs, the formation of structural consequences caused by the "big horse car" type of waste

- Yes, geogrids can be used in bridge abutment reinforcement. Geogrids are commonly used in civil engineering projects to improve the stability and strength of soil structures, such as bridge abutments. They provide additional tensile strength and prevent soil erosion, helping to enhance the overall performance and longevity of the bridge abutment.

- What are the types of geogrid, respectively, what role?

- Glass fiber geogrid is a kind of excellent geosynthetic material used for Pavement Strengthening, strengthening of old road, strengthening subgrade and soft soil foundation. It has become an irreplaceable material in the application of reflective cracking in asphalt pavement. The product is made of high strength alkali free glass fiber through international advanced warp knitting process made of mesh substrate, the surface coating processing made of semi-rigid products. With the warp and weft two-way high tensile strength and low elongation, and high temperature resistance, low temperature, aging resistance, corrosion resistance and other excellent properties, is widely used in the asphalt pavement, cement concrete pavement and subgrade reinforcement and railway roadbed, dam slope, airport runway, anti sand control project.