Geocomposite Drain Installation

Geocomposite Drain Installation Related Searches

Geocomposite Sheet Drain Geocomposite Drainage Board Geocomposite Drainage Material Geocomposite Drainage Strip Geocomposite Drainage Mat Geocomposite Strip Drain Geocomposite Drainage Layer Cost Geocomposite Drainage Net Geomembrane Drainage Hdpe Granules IncHot Searches

Geocomposite Manufacturers Tesla Solar Roof Inverter Pool Light Installation Cost Geomembrana Home Depot 30 Year Roof Shingles Prices Tensar Geogrid Installation Wholesale Liner Hdpe Geomembrane Wholesale Hdpe Geomembrana Hdpe Geomembrane Liner Manufacturers Hdpe Liner Cost Hdpe Pond Liner Specifications Geosynthetic Clay Liner Cost Landfill Liner Cost Geocomposite ManufacturersGeocomposite Drain Installation Supplier & Manufacturer from China

Okorder.com is a professional Geocomposite Drain Installation supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Geocomposite Drain Installation firm in China.Hot Products

FAQ

- Yes, geotextiles are commonly used in canal bank protection. They are often used as a reinforcement material to prevent soil erosion and provide stability to canal banks. Geotextiles help to distribute loads and reduce the risk of bank failure, making them an effective solution for canal bank protection.

- When maintaining geotextiles, there are several factors to consider. Firstly, it is important to regularly inspect the geotextiles for any signs of damage or wear. This includes checking for tears, holes, or fraying, as well as monitoring the overall condition of the material. Secondly, it is crucial to properly clean the geotextiles to prevent the buildup of dirt, debris, or organic matter that can compromise their effectiveness. This may involve using appropriate cleaning methods such as gentle washing or vacuuming. Additionally, considering the environmental and weather conditions in the specific location where the geotextiles are installed is essential. Extreme temperatures, UV exposure, and moisture levels can impact the durability and longevity of the material, so appropriate protective measures should be taken to mitigate these factors. Lastly, regular maintenance should include reassessing the performance of the geotextiles and their compatibility with the intended application. This may involve consulting with experts or conducting periodic testing to ensure that the geotextiles continue to meet the required standards and objectives. Overall, diligent inspection, cleaning, protection, and evaluation are key factors to consider when maintaining geotextiles.

- Such as title. The manager asked them to be made into a square meter compound. What materials can be used to bind them live. 502 glue can not be filled Cao Cao 丨 not only check the intestine Lu adhesive can not be used, glue rods can be used, but EVA is transparent after the appearance of poor adhesion. Neighborhoods. More

- EVA has a special adhesive material

- When selecting geotextiles for mining applications, several factors need to be considered. These include the required strength and durability of the geotextile to withstand the specific mining conditions, such as heavy loads, abrasion, and chemical exposure. The geotextile's filtration and drainage properties are also crucial in managing water flow and preventing soil erosion. Additionally, the geotextile's ability to resist biological degradation and UV radiation should be evaluated to ensure long-term performance. Lastly, cost-effectiveness and compliance with environmental regulations should be taken into account during geotextile selection for mining applications.

- What is the role of the laying of geotextiles at the bottom of the grassland?

- From the soil and soil, fixed slope protection, anti-erosion, anti-filter (over the water, but soil) and other effects, I professional production geotextile, geomembrane and other products, wish smooth

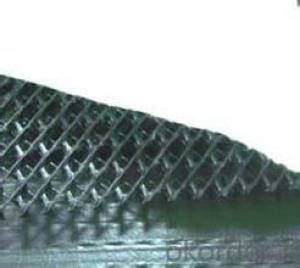

- The installation guidelines for geotextiles in reinforcement projects typically involve the following steps: 1. Site Preparation: Clear the construction area of any vegetation, debris, or loose soil. Level the ground and remove any protrusions or sharp objects that could damage the geotextile. 2. Geotextile Placement: Unroll the geotextile over the prepared area, ensuring it covers the entire project site. Overlaps between adjacent rolls should be at least 1 to 2 feet to provide proper continuity. 3. Anchoring: Secure the geotextile at the edges using anchor trenches, stakes, or other appropriate methods to prevent movement during installation or in the long term. 4. Jointing: Overlap adjacent geotextile panels by a minimum of 1 to 2 feet, depending on the project requirements. Secure the overlap with appropriate fasteners or adhesives to ensure proper functioning. 5. Protection: If necessary, cover the geotextile with a protective layer, such as a layer of soil or aggregate, to shield it from potential damage during construction activities or exposure to UV radiation. 6. Compaction: If the project involves soil stabilization or reinforcement, follow the recommended compaction procedures to ensure proper integration of the geotextile with the surrounding soil or aggregate. 7. Quality Control: Regularly inspect the geotextile installation to ensure that it is properly placed, free of damage, and functioning as intended. Any identified issues should be addressed promptly. It is important to note that specific installation guidelines may vary depending on the project type, site conditions, and the type of geotextile being used. It is recommended to consult the manufacturer's recommendations and seek professional guidance to ensure proper installation.

- Geotextile unit why is g / square meter why do not use the thickness of the unit

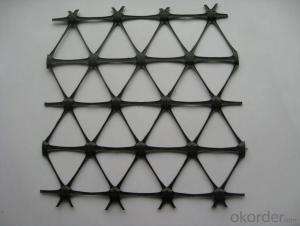

- Geotextile, also known as geotextile, it is made of synthetic fiber through acupuncture or woven from the permeability of geosynthetics. Geotextile is a new material geosynthetics which one, the finished product for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a spinning geotextile and non-woven filament geotextile.

- Roof garden pool at the bottom with pebbles, pebbles above with geotextile, geotextile above the soil

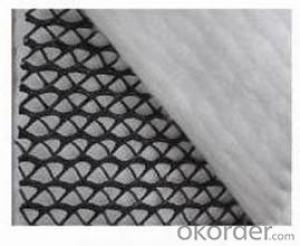

- Geotextile laying on the soil can be, goose soft stone has replaced the effectiveness of the drainage board. Geotextile play a filtering effect, the excess water through the cloth, go through goose soft stone flow. Soil is geotextile interception, will not be lost, plug the drain, Huazhi geotextile material manufacturers.