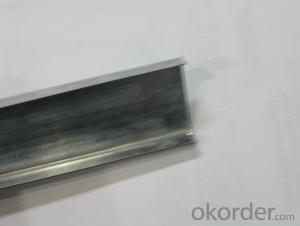

Galvanized Steel Angle

Galvanized Steel Angle Related Searches

Best Paint For Stainless Steel Paint For Galvanized Steel Steel Frames For Furniture Self Tapping Screws For Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For Bbq Step Bit For Stainless Steel Sponge For Stainless SteelHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Used Solar Inverter For Sale Steel Mesh Panels For SaleGalvanized Steel Angle Supplier & Manufacturer from China

Okorder.com is a professional Galvanized Steel Angle supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Galvanized Steel Angle firm in China.Hot Products

FAQ

- Yes, steel angles can be used for framing or supporting suspended ceilings. Steel angles provide excellent structural support and can be easily attached to the walls or ceiling to create a sturdy framework for suspended ceilings. They are commonly used in construction and are known for their strength and durability, making them suitable for this purpose.

- Steel angles perform well in extreme temperatures due to their high strength and excellent heat resistance. They retain their structural integrity and do not easily deform or become brittle under extreme heat or cold conditions. This makes steel angles a reliable choice for various applications in industries such as construction, manufacturing, and engineering, where exposure to extreme temperatures is common.

- Yes, steel angles can definitely be used for decorative purposes. Steel angles are versatile and can be shaped and formed into various designs and patterns, making them a popular choice for adding a decorative touch to interior and exterior spaces. They can be used to create decorative accents such as trim, frames, and brackets. Additionally, steel angles can be easily painted or powder-coated in different colors to match any desired aesthetic. The durability and strength of steel angles also ensure that they will withstand the test of time, making them a practical and attractive option for decorative applications.

- There are several methods of reinforcing steel angles, each with its own advantages and applications. One common method is the use of additional steel plates or brackets. These plates or brackets are typically welded or bolted to the existing steel angle to provide additional support and strength. This method is often used in applications where the steel angle is subject to high loads or stresses. Another method is the use of stiffeners, which are typically smaller steel angles or plates welded perpendicular to the existing angle. These stiffeners help to distribute the load more evenly and prevent the steel angle from buckling or bending under stress. This method is often used in applications where the steel angle is used as a structural member, such as in building frames or bridge supports. Additionally, reinforcing steel angles can be achieved through the use of concrete encasement or composite materials. In this method, the steel angle is embedded within a concrete matrix or combined with other materials such as fiberglass or carbon fiber. This combination provides enhanced strength, durability, and resistance to corrosion. This method is commonly used in construction projects where the steel angle is exposed to harsh environments or requires high performance. Overall, the different methods of reinforcing steel angles provide options for increasing the strength, stability, and durability of these structural components. The choice of method will depend on the specific application, load requirements, and environmental factors.

- The maximum allowable lengths for steel angles can vary depending on the specific application and the regulations and guidelines set forth by the relevant industry standards. Generally, the maximum allowable lengths for steel angles are determined by factors such as the material's strength, the load it is intended to bear, and the structural design considerations. In construction and engineering industries, steel angles are commonly used for various structural applications such as framing, bracing, and support. The maximum allowable lengths for steel angles are often specified by building codes, engineering standards, or project-specific design criteria. These regulations ensure that the angles can withstand the expected loads and provide adequate structural stability. It is important to consult the appropriate industry standards and regulations, as well as consult with a qualified structural engineer or designer, to determine the maximum allowable lengths for steel angles in a specific application. These professionals take into account factors such as the angle's dimensions, thickness, material properties, and the specific load requirements to determine the appropriate length that can safely and effectively meet the project requirements.

- The maximum allowable compressive stress for a steel angle depends on various factors such as the grade of steel, the dimensions and geometry of the angle, and the specific application or industry standards. Generally, steel angles are designed to withstand compressive loads, which push or squeeze the material together. To determine the maximum allowable compressive stress for a steel angle, it is essential to refer to structural design codes and standards, such as the American Institute of Steel Construction (AISC) Manual or Eurocode. These standards provide guidelines and formulas for calculating the maximum allowable compressive stress based on the steel grade and the cross-sectional properties of the angle. For instance, the AISC Manual provides a formula to calculate the nominal compressive strength of a steel angle based on its slenderness ratio. The slenderness ratio is the ratio of the length of the angle to its radius of gyration, which measures how slender or compact the angle is. The formula takes into account the yield strength of the steel and the slenderness ratio to determine the maximum compressive stress the angle can sustain without buckling. It is important to note that the maximum allowable compressive stress should not exceed the yield strength of the steel angle. The yield strength is the point at which the material begins to deform permanently, and exceeding this limit can lead to structural failure. Therefore, to accurately determine the maximum allowable compressive stress for a steel angle, it is recommended to consult relevant design codes and standards, or consult with a structural engineer who can assess the specific application and provide a precise answer based on the pertinent factors.