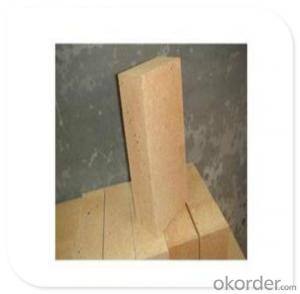

Fire Clay

Fire Clay Related Searches

H S Code For Stainless Steel Wd 40 For Stainless Steel Spray Paint For Stainless Steel Drill Bits For Stainless Steel Steel Vessels For Kitchen Led Floor Lamps For Home Led Light For Chandelier Hot Water Bags For Pain Relief Shade Cover For Solar Inverter Led Headlight Kits For TrucksHot Searches

Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Bags Of Cement For Sale Tilt Panel Props For Sale Types Of Temporary Side Panels For Cement Deck Cost Of Awnings For Decks Type Of Scaffolding With Pdf Price Of Scrap Stainless Steel Price Of Stainless Steel Scrap Type Of Stainless Steel Gypsum Board Price Per Sheet In India Types Of Stainless Steel Grades Types Of Stainless Steel Aluminum Corp Of China Stock Types Of Scaffolding In Construction Pdf Price Of Solar Cells Over Time Price Of Aluminum Stock Types Of Raw Materials Used In Industries Type Of Inverter For SolarFire Clay Supplier & Manufacturer from China

Okorder.com is a professional Fire Clay supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Fire Clay firm in China.Hot Products

FAQ

- Material and making method of light insulating brick

- The strength products are made of high quality tabular corundum and mullite as aggregate, silicon carbide as matrix, additional special additive and a small amount of rare earth oxide to be mixed, and then formed by high pressure molding and high temperature sintering.

- Yes, insulating fire bricks are suitable for insulation in cryogenic applications. Insulating fire bricks have excellent thermal insulation properties, low thermal conductivity, and can withstand extremely low temperatures. This makes them ideal for use in cryogenic applications where insulation is required to maintain the low temperature of the system.

- The dimensions of insulating fire bricks can vary, but they are typically rectangular in shape and commonly come in sizes such as 9" x 4.5" x 2.5" or 9" x 4.5" x 3".

- Yes, insulating fire bricks can be used in brick ovens. Insulating fire bricks are designed to withstand high temperatures and provide excellent heat insulation, making them ideal for use in brick ovens. These bricks are made from lightweight refractory materials, which help to reduce heat loss and improve the overall energy efficiency of the oven. Additionally, insulating fire bricks are resistant to thermal shock, meaning they can withstand rapid changes in temperature without cracking or breaking. This makes them a reliable and durable choice for brick oven construction.

- Insulating fire bricks have the capability to be utilized in the construction of flue gas ducts. These bricks are specifically engineered to endure high temperatures and offer exceptional thermal insulation. This makes them an apt choice for lining flue gas ducts as they aid in reducing heat loss and enhancing energy efficiency. Moreover, insulating fire bricks exhibit resistance to chemical corrosion and can withstand the harmful impacts of flue gases. Nevertheless, it is crucial to guarantee that the insulating fire bricks employed are specifically designed for flue gas duct applications and fulfill the required safety and regulatory standards. Seeking advice from a professional engineer or a specialist in this field is advised to ensure the accurate selection and installation of insulating fire bricks in flue gas ducts.

- Yes, insulating fire bricks can be used in the construction of ladles. Insulating fire bricks are made from lightweight materials that have excellent thermal insulation properties. This makes them ideal for applications where heat needs to be retained or controlled, such as in the construction of ladles used in metal or glass industries. The insulating fire bricks help to reduce heat loss, improve energy efficiency, and maintain the desired temperature within the ladle. Additionally, their lightweight nature makes them easier to handle and install in ladle constructions. Therefore, insulating fire bricks can be a suitable choice for ladle construction, providing the necessary thermal insulation and durability required for these high-temperature applications.

- Indeed, insulating fire bricks find utility in the kilns of the ceramic industry. These bricks are specially crafted to endure extreme temperatures and offer insulation within kilns. With their low thermal conductivity, they facilitate the preservation of uniform heat distribution, thus enhancing the efficiency of firing procedures. Moreover, their lightweight nature simplifies their handling and installation in kilns. The bricks' capacity to retain heat and withstand thermal shock renders them an optimal selection for employment in ceramic industry kilns.