Fiberglass Roving

Fiberglass Roving Related Searches

Led Light Bulbs For Ceiling Fixtures Decorative Ceiling Plate For Light Fixture Ceiling Plate For Hanging Light Fiberglass Sheets For Roofing Track Lights For Kitchen Ceiling Lights For Kitchen Ceiling Lights For Fall Ceiling Spotlight For Ceiling 5 Blade Ceiling Fan With Light 12X12 Ceiling Tiles With HolesHot Searches

Fiberglass Scaffolding For Sale Plastic Roof Tiles For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale Cost Of Concrete Tile Roof Roof Insulation Price Artificial Slate Roof Tiles Price Ceiling Fan Lowest Price Tesla Solar Roof Inverter Types Of Flat Roof Coverings Stone Wall Tiles Cost Company Office Design Ceramic Roof Tiles Cost Metal Roof Tiles Prices Cement Roof Tile Manufacturers Clay Roof Tile Manufacturers Synthetic Roof Tiles Cost Roof Clay Tiles Prices Interlocking Roof Tiles Prices 30 Year Roof Shingles PricesFiberglass Roving Supplier & Manufacturer from China

Okorder.com is a professional Fiberglass Roving supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Fiberglass Roving firm in China.Hot Products

FAQ

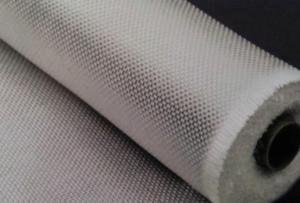

- Fiberglass mat tissue, also known as fiberglass mat or fiberglass matting, is a type of non-woven material made from glass fibers. It possesses several properties that make it suitable for various applications. 1. Strength and durability: Fiberglass mat tissue is known for its high tensile strength, which means it can withstand significant amounts of stress without breaking. This property makes it ideal for reinforcing and strengthening different materials and structures. 2. Lightweight: Despite its strength, fiberglass mat tissue is relatively lightweight, making it easy to handle and transport. This property is particularly advantageous in industries where weight reduction is important, such as aerospace and automotive. 3. Flexibility: Fiberglass mat tissue is flexible, which allows it to conform to curved surfaces and complex shapes. This property makes it versatile and suitable for applications where the material needs to be molded or formed into specific designs. 4. Chemical resistance: Fiberglass mat tissue has excellent resistance to various chemicals, including acids, alkalis, and most solvents. This property makes it suitable for applications in corrosive environments, such as chemical processing plants or storage tanks. 5. Thermal insulation: Fiberglass mat tissue has good thermal insulation properties, meaning it can help to reduce heat transfer. This property makes it useful in applications where heat insulation is required, such as in the construction of walls, roofs, or insulation boards. 6. Fire resistance: Fiberglass mat tissue is inherently fire-resistant and does not contribute to the spread of flames. This property makes it widely used in applications where fire safety is essential, such as in the production of fire-resistant doors, panels, or insulation materials. 7. Sound insulation: Fiberglass mat tissue also offers good sound insulation properties, reducing noise transmission through walls or other structures. This property makes it suitable for use in soundproofing applications, such as in recording studios or automotive interior panels. Overall, the properties of fiberglass mat tissue make it a versatile material with a wide range of applications in various industries, including construction, automotive, aerospace, and marine. Its strength, flexibility, lightweight, chemical resistance, thermal and sound insulation properties, as well as its fire resistance, contribute to its popularity and usefulness in many different applications.

- The typical dimensions and roll sizes of fiberglass mat tissue can vary depending on the specific product and manufacturer. However, in general, fiberglass mat tissue is commonly available in rolls with widths ranging from 1 to 6 feet and lengths ranging from 100 to 1000 feet. The thickness of the tissue can range from 0.5 to 1.5 millimeters. Some manufacturers may offer custom sizes and lengths to suit specific project requirements. It is always recommended to consult the manufacturer or supplier for the exact dimensions and roll sizes of fiberglass mat tissue.

- Fiberglass mat tissue is indeed a viable option for the production of insulation boards. This lightweight and flexible material is frequently employed in the creation of insulation boards. It boasts exceptional thermal insulation capabilities, as well as the ability to absorb sound and resist fire. The process of layering and compressing the mat tissue is typically employed to manufacture these insulation boards, resulting in a robust and efficient barrier against heat transfer. Furthermore, fiberglass mat tissue is impervious to moisture, mold, and pests, making it a trustworthy choice for insulation purposes. In summary, the insulation performance, durability, and resistance to environmental elements make fiberglass mat tissue a suitable choice for the construction of insulation boards.

- Indeed, fiberglass mat tissue proves to be a fitting choice for aerospace repairs. This lightweight and pliable material can be effortlessly shaped and applied to various surfaces. Its exceptional strength-to-weight ratio makes it particularly suitable for circumstances where weight plays a crucial role, such as aerospace repairs. Aerospace repairs frequently employ fiberglass mat tissue to fortify areas of the aircraft structure that have been compromised or weakened. By doing so, it ensures outstanding structural integrity and longevity, enabling the repaired region to endure the demanding conditions and stresses encountered during flight. Moreover, fiberglass mat tissue demonstrates compatibility with various resin systems, including epoxy and polyester. This allows for efficient bonding, guaranteeing a dependable repair. Its versatility permits it to be utilized in both interior and exterior repairs, such as patching up composite panels, reinforcing wing sections, or rectifying damaged fuselage areas. Beyond its mechanical attributes, fiberglass mat tissue also exhibits exceptional resistance to corrosion, moisture, and chemicals. This enhances the durability of the repaired components, a particularly important feature in aerospace applications where the aircraft is frequently exposed to harsh environmental conditions. All in all, fiberglass mat tissue emerges as a suitable material for aerospace repairs due to its lightweight nature, impressive strength, versatility, and resistance to environmental factors. Its use in the aerospace industry has been firmly established, and it remains a dependable choice for repairing and reinforcing critical aircraft components.

- Fiberglass mat tissue can be used to insulate HVAC ducts, as it possesses excellent thermal and acoustic properties. It is a widely utilized material for insulation, thanks to its ability to endure high temperatures and resist moisture. This makes it perfect for applications in ductwork. By reducing heat transfer and preventing condensation buildup, fiberglass mat tissue provides effective insulation for the ducts. Moreover, it is lightweight, simple to install, and has a lengthy lifespan. Consequently, it is a cost-effective option for HVAC insulation. In conclusion, fiberglass mat tissue is a dependable and appropriate choice for insulating HVAC ducts.

- The moisture resistance rating of fiberglass mat tissue can vary depending on the specific product and manufacturer. However, in general, fiberglass mat tissue is known for its excellent moisture resistance properties. It is typically designed to be highly resistant to water absorption, making it suitable for use in applications where moisture exposure is a concern. This moisture resistance helps to maintain the structural integrity and performance of the fiberglass mat tissue, even in humid or wet conditions. It is important to note that when selecting fiberglass mat tissue for a specific application, it is recommended to refer to the product specifications provided by the manufacturer to determine the precise moisture resistance rating.

- Yes, fiberglass mat tissue is resistant to mold growth. Fiberglass is made from glass fibers that are tightly woven together, creating a material that is highly resistant to moisture and mold. Additionally, fiberglass is non-porous, meaning it does not absorb water, which further inhibits the growth of mold. This makes fiberglass mat tissue an ideal choice for applications where mold resistance is important, such as in insulation, wallboards, and other construction materials.

- Yes, fiberglass mat tissue is suitable for railway infrastructure. Fiberglass mat tissue is a strong and durable material that offers excellent resistance to corrosion, weathering, and chemical degradation. It is commonly used in the construction industry for reinforcing structures such as bridges, tunnels, and platforms. In the case of railway infrastructure, fiberglass mat tissue can provide several benefits. Firstly, it has high tensile strength, which means it can withstand the heavy loads and vibrations associated with train traffic. This helps to prevent cracking and structural damage, ensuring the longevity and safety of the railway system. Additionally, fiberglass mat tissue is non-conductive, which is a crucial characteristic for railway infrastructure. It helps to prevent the risk of electrical shocks and short circuits, which are common concerns in rail networks. This makes fiberglass mat tissue a reliable choice for railway infrastructure, especially in areas where electrical lines are present. Furthermore, fiberglass mat tissue is lightweight and easy to handle, making it convenient for installation in railway projects. It is also resistant to fire, making it a safe choice for railway infrastructure in terms of fire protection. Overall, fiberglass mat tissue is a suitable material for railway infrastructure due to its strength, durability, non-conductive nature, and fire resistance. Its use in railway construction can contribute to the reliability, longevity, and safety of the railway system.