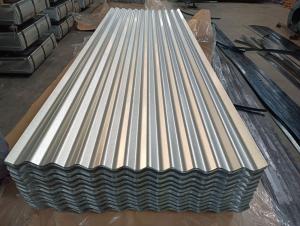

Corrugated Perspex Sheet

Corrugated Perspex Sheet Related Searches

Primer For Galvanized Steel Msds Sheet For Magnesium Grinding Tools For Metal Metal Frames For Beds Metal Bar Chairs With Backs High Temperature Clear Plastic Sheet Galvanized Steel Wall Panels Galvanized Steel Sheet 4x8 Galvanized Steel Garden Beds 16 Gauge Sheet SteelHot Searches

Pvc Chairs For Sale Plastic Roof Tiles For Sale Heavy Duty Plastic Chairs For Sale Plastic Sheets For Sale Fiber Sheet Price In India Gypsum Board Price Per Sheet In India pvc pipe manufacturers in usa Stainless Steel Sheet Near Me Plastic Fiber Sheet Price Upvc Roofing Sheet Manufacturer In India China Pvc Geomembrane China Geomembrane Roll Sheet Pvc Roofing Sheets Price India Pvc Roofing Sheets Price 5 8 Type X Gypsum Board Price Gypsum Board Price Per Sheet pvc resin price index Lasani Wood Sheet Price Rhino Roofing Sheet Price List Tinplate Sheet PriceCorrugated Perspex Sheet Supplier & Manufacturer from China

Okorder.com is a professional Corrugated Perspex Sheet supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Corrugated Perspex Sheet firm in China.Hot Products

FAQ

- The quality and compliance of the steel sheets are ensured through specific certifications. These certifications are typically granted by reputable organizations like the International Organization for Standardization (ISO) or specific regulatory bodies based on the country or region. The common certifications for steel sheets include ISO 9001 for quality management systems, ISO 14001 for environmental management systems, and ISO 45001 for occupational health and safety management systems. Furthermore, there might be industry-specific certifications, such as the American Society for Testing and Materials (ASTM) standards or the European Committee for Standardization (EN) certifications. These certifications guarantee that the steel sheets meet specific criteria for various attributes, including material composition, mechanical properties, and manufacturing processes.

- Yes, steel sheets are suitable for agricultural applications. They are durable, corrosion-resistant, and can withstand harsh weather conditions, making them ideal for various agricultural purposes such as constructing sheds, barns, fences, and storage buildings. Additionally, steel sheets can be easily fabricated and customized to meet specific agricultural needs.

- Indeed, machinery parts can be manufactured using steel sheets. Steel, as a material, possesses remarkable versatility and durability, thereby offering exceptional strength and rigidity necessary for the production of diverse machinery components. The malleability, ease of cutting, and weldability of steel sheets enable the creation of intricate shapes and structures essential for machinery parts. Furthermore, steel exhibits commendable resistance against corrosion, guaranteeing the longevity of the machinery components. Moreover, steel sheets ensure dimensional stability and can endure substantial loads and elevated temperatures, rendering them a perfect selection for the manufacturing of machinery parts.

- Yes, steel sheets are generally resistant to chemicals. Steel is known for its strong and durable nature, which makes it highly resistant to corrosion caused by various chemicals. However, the level of resistance may vary depending on the specific type and grade of steel used, as well as the type and concentration of the chemicals involved. In certain cases, such as exposure to highly corrosive substances like acids or alkalis, additional protective measures like coatings or surface treatments may be necessary to enhance the chemical resistance of steel sheets.

- Architectural projects can indeed utilize steel sheets as they offer numerous advantages. Steel, being a versatile and durable material, is highly suitable for such applications. First and foremost, steel sheets possess immense strength, enabling them to bear heavy loads. This makes them perfect for structural elements in buildings. The high strength-to-weight ratio of steel sheets allows for the creation of large and open spaces without the need for excessive supporting columns or walls. Consequently, steel sheets are ideal for constructing expansive interior spaces like atriums, stadiums, and other architectural projects. Furthermore, steel sheets can be easily shaped and formed into various architectural designs. They can be curved, rolled, or bent to fashion unique and intricate structures. Steel's malleability empowers architects and designers to challenge conventional building designs and create visually stunning and innovative structures. Moreover, steel sheets exhibit resistance to corrosion, weathering, and fire, making them suitable for outdoor applications and ensuring the longevity of architectural projects. The durability of steel also translates into minimal maintenance requirements throughout its lifespan, resulting in long-term cost savings. In addition, steel sheets offer a wide range of finishes, textures, and colors, facilitating customization and aesthetic versatility in architectural projects. Whether aiming for a sleek and modern design or a rustic and industrial look, steel sheets can be tailored to meet the desired aesthetic requirements of the project. To sum up, steel sheets are an excellent choice for architectural projects owing to their strength, versatility, durability, and aesthetic appeal. Their ability to withstand heavy loads, be shaped into various designs, resist corrosion and fire, and offer customization options make them a favored material for architects and designers to turn their visions into reality.

- The typical price range for steel sheets can vary depending on factors such as size, thickness, grade, and market conditions. However, generally speaking, steel sheets can range in price from around $20 to $200 per sheet.

- Yes, steel sheets are suitable for automotive body parts. Steel is a commonly used material in the automotive industry due to its strength, durability, and ability to withstand high impact. Steel sheets provide excellent structural integrity and can be easily formed into various shapes to create automotive body panels. Additionally, steel is cost-effective and readily available, making it a preferred choice for manufacturing automotive body parts.