Cold Rolled C Channel Thailand

Cold Rolled C Channel Thailand Related Searches

Paint For Galvanized Steel Steel Frames For Furniture Self Tapping Screws For Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Step Bit For Stainless Steel Bending Machine For Pvc Profiles Stainless Steel Bucket With Lid High Five Stainless Steel Prop Grinding Wheels For MetalHot Searches

Inverter Size For Solar System Used Metal Folding Chairs For Sale Large Metal Containers For Sale Metal Shop Cabinets For Sale Metal Shipping Crates For Sale Large Size Aluminum Foil Aluminum Foil Market Size Solar Inverter Market Size Solar Inverter Size Chart Aluminum Channel Stock Sizes Metal Roof Tiles Prices Metal Furniture Company Type C Fuse Type C Sheetrock Geomembrane Market Size Geogrid Aperture Size Inverter Size For Solar System Used Metal Folding Chairs For Sale Large Metal Containers For Sale Metal Shop Cabinets For SaleCold Rolled C Channel Thailand Supplier & Manufacturer from China

Okorder.com is a professional Cold Rolled C Channel Thailand supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Cold Rolled C Channel Thailand firm in China.Hot Products

FAQ

- Yes, steel channels can be used in the telecommunications industry. They are commonly used for cable management and support structures in telecommunication installations due to their strength, durability, and ability to handle heavy loads.

- Is the bottom of the channel not real? Why do we open the hole? What's the reason?

- Is the most ideal processing equipment of stainless steel and flat iron, steel, steel, iron pipes and other processing households, profile processing businesses.

- Yes, steel channels can be used in the pharmaceutical industry. Steel channels are versatile structural components that are commonly used in various industries, including pharmaceuticals. They serve as support structures for mechanical equipment, such as conveyors and processing machines, in pharmaceutical manufacturing facilities. Steel channels provide stability, strength, and durability, making them suitable for applications that require heavy loads and rigorous hygiene standards. Additionally, steel channels can be easily cleaned and sanitized, which is crucial in the pharmaceutical industry to maintain a sterile environment and prevent contamination.

- No, steel channels are not typically used for roofing applications. Steel channels are generally used in structural applications such as supporting beams, columns, and framing in construction projects. For roofing applications, materials such as metal panels, asphalt shingles, clay or concrete tiles, or even thatched roofing are commonly used. These materials are specifically designed and manufactured to provide weatherproofing, insulation, and durability to protect the structure and its occupants from outside elements. While steel channels may have other important uses in construction, they are not suitable for roofing applications as they do not provide the necessary qualities required for an effective and long-lasting roof.

- 8# what's the size of the channel steel?

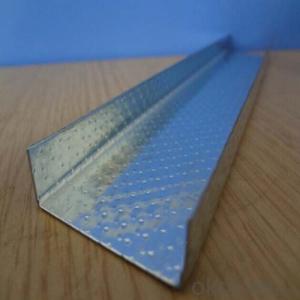

- Channel steel is a kind of carbon structural steel used for construction and machinery. It is a complex section steel. Its cross section has a groove shape. Channel steel is mainly used in building structure, curtain wall engineering, mechanical equipment and vehicle manufacturing, etc.. In use, it requires better welding, riveting performance and comprehensive mechanical properties. The raw material steel billet for channel steel is carbon or low alloy steel billets with a carbon content of not more than 0.25%. The finished channel steel is delivered by hot forming, normalizing or hot rolling. The specifications are expressed in millimeters of height (H) * leg width (b) * waist thickness (d), such as 100*48*5.3, which means waist height is 100 mm, leg width is 48 mm, waist thickness is 5.3 mm channel, or 10# channel steel. The same height of the channel, if there are several different leg width and waist thickness, also need to add a, B, C on the right side of the model to distinguish, such as 25#a, 25#b, 25#c and so on.

- What do you mean by channel 8 A?

- 8# refers to the channel width 80mm, the same type of channel is general a, B, a, B is the wing plate channel of different sizes

- Steel channels perform exceptionally well in high-load applications due to their high strength and load-bearing capabilities. The design of steel channels allows for efficient distribution of weight, making them ideal for supporting heavy loads and withstanding significant stresses. The structural integrity of steel channels ensures that they can handle the demands of high-load applications without compromising safety or performance. Steel channels are commonly used in construction, automotive, and industrial sectors where there is a need to support heavy equipment, structures, or machinery. Their robustness and durability make them reliable and long-lasting, even under extreme conditions. Additionally, steel channels have excellent resistance to bending, twisting, and warping, making them suitable for withstanding dynamic loads and vibrations. Another advantage of steel channels in high-load applications is their versatility. They come in various sizes, shapes, and thicknesses, allowing engineers to select the most suitable channel for a specific application. This flexibility in design ensures an optimal fit for different load requirements, giving engineers the ability to optimize the load-bearing capacity while minimizing weight and material costs. Furthermore, steel channels have good corrosion resistance, especially when coated with protective treatments or finishes. This enables them to withstand harsh environmental conditions and maintain their performance over time. Additionally, steel channels can be easily welded, bolted, or fastened together, providing flexibility in construction and allowing for easy customization or modification as needed. In summary, steel channels are highly reliable and efficient in high-load applications. Their strong and durable nature, along with their versatility and resistance to bending and corrosion, make them an excellent choice for supporting heavy loads in various industries.

- There are several different types of surface finishes that can be used for steel channels in architectural applications. These finishes not only enhance the aesthetic appeal of the steel channels but also provide protection against corrosion and wear. Here are some common types of surface finishes for steel channels: 1. Mill Finish: This is the basic finish that steel channels have when they are initially manufactured. It has a dull gray appearance and is typically rough in texture. Mill finish steel channels are often used in industrial applications where aesthetics are not a primary concern. 2. Hot-Dip Galvanized: This finish involves dipping the steel channels into a bath of molten zinc, creating a thick layer of zinc coating on the surface. Hot-dip galvanized steel channels have a shiny, silver appearance and provide excellent corrosion resistance, making them suitable for outdoor architectural applications. 3. Powder Coating: Powder coating is a popular surface finish for steel channels in architectural applications. It involves applying a dry powder to the surface and then heating it to form a durable, protective layer. Powder coating provides a smooth, even finish and is available in a wide range of colors, allowing for customization and design flexibility. 4. Stainless Steel: Steel channels can also be fabricated from stainless steel, which inherently provides a corrosion-resistant finish. Stainless steel channels have a sleek, modern appearance and are often used in architectural designs that require a high-end, polished finish. 5. Painted Finish: Steel channels can be painted with various types of paint to achieve a desired color and finish. Painted finishes offer versatility and can be customized to match the architectural design. However, they may require periodic maintenance to prevent chipping or fading. 6. Brushed or Polished Finish: Brushed or polished finishes involve mechanically abrading the steel channels to create a smooth, reflective surface. These finishes are commonly used in architectural applications where a high-quality, decorative appearance is desired. Each type of surface finish for steel channels in architectural applications has its own characteristics and advantages. The choice of finish depends on factors such as the desired appearance, level of corrosion resistance required, and the specific environmental conditions the steel channels will be exposed to.