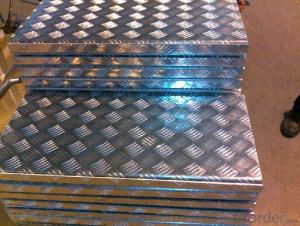

Aluminum Tread Plate Fenders

Aluminum Tread Plate Fenders Related Searches

Led Light Bulbs For Ceiling Fixtures Led Lamps For Ceiling 42 In Ceiling Fan With Light Aluminum Coil Stock For Gutters Aluminum Foil For The Grill Hole Saw For Aluminum Plate Aluminum Tread Plate For Trailer Bow Plate For Aluminum Boat Aluminum Foil For Grow Room Aluminum Foil For Joint PainHot Searches

Stock Price For Aluminum Aluminum Coil Stock For Sale Aluminum Gutter Coil For Sale Used Aluminum Scaffolding For Sale 1/4 Aluminum Plate For Sale Aluminum Bar Stock For Sale Aluminum Round Stock For Sale Aluminum Diamond Plate For Sale Aluminum Scaffolding For Sale Craigslist 6061 Aluminum Plate For Sale Aluminum Dock Plate For Sale 7075 Aluminum Plate For Sale Aluminum Tread Plate For Sale Aluminum Checker Plate For Sale Aluminum Plate For Sale Near Me Plate Aluminum For Sale Aluminum Plate For Sale Aluminum Square Stock For Sale Aluminum Flat Stock For Sale Billet Aluminum Stock For SaleAluminum Tread Plate Fenders Supplier & Manufacturer from China

Okorder.com is a professional Aluminum Tread Plate Fenders supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Aluminum Tread Plate Fenders firm in China.Hot Products

FAQ

- Certainly! Nameplates or tags can be produced using 101 aluminum sheets. The durability, lightweight nature, and corrosion resistance of aluminum make it a popular material choice for such items. The 101 aluminum alloy, which is a commercially pure aluminum, offers excellent formability and workability. This makes it suitable for various manufacturing processes like stamping, engraving, or etching. It can be easily cut, shaped, and customized to create nameplates or tags with clear and precise markings. Moreover, aluminum's ability to withstand harsh environments and its appealing appearance make it preferred across industries like automotive, aerospace, electronics, and signage. Hence, 101 aluminum sheets are a suitable material for producing nameplates or tags.

- A solid aluminum sphere has a mass of 83 g.Use the density of aluminum to find the radius of the sphere in inchesExpress your answer using two significant figures.I can't figure this out :(

- Aluminum's density is about 2.7 grams per cubic centimeter. So a sphere with a mass of 84grams has a volume of about 31.111 cubic centimeters. You get this by dividing 84 by 2.7. Now that you know the volume, you can calculate the radius of the sphere. for a sphere, volume = 4/3 pi * radius to the third power. So 31.111 = 4/3 * (3.14...) * r^3. Divide both sides by 4/3 then divide both sides by pi and you get something like r^3 is 7.427. Then find the cube root of this to find your radius. I don't have a calculator, so someone should check the numbers.

- There are several methods of surface protection for outdoor aluminum sheet to ensure its durability and longevity. 1. Anodizing: This is one of the most common methods used to protect aluminum surfaces. Anodizing creates a protective oxide layer on the surface, making it more resistant to corrosion, abrasion, and UV rays. It also improves the appearance of the aluminum sheet by providing a range of colors and finishes. 2. Powder coating: Powder coating involves applying a dry powder to the aluminum sheet and then baking it in an oven to create a hard, protective coating. This method provides excellent resistance to weathering, corrosion, and chemicals. It is also available in various colors and finishes. 3. Paint coating: Applying a paint coating is another effective way to protect outdoor aluminum sheets. The paint forms a barrier between the aluminum surface and the environment, preventing corrosion and enhancing aesthetics. It is important to use a high-quality paint specifically designed for aluminum to ensure proper adhesion and durability. 4. Clear coating: Clear coating is mainly used to protect the natural appearance of aluminum while providing a layer of protection against corrosion, oxidation, and UV rays. It is often applied after anodizing or polishing the aluminum sheet. 5. Laminating: Laminating involves adhering a protective film or sheet onto the aluminum surface. This method provides excellent resistance to scratches, abrasion, and UV rays. It is commonly used in applications where the aluminum sheet is subjected to heavy wear and tear. 6. Chemical conversion coating: Chemical conversion coatings, such as chromate conversion coating or phosphating, are used to improve the corrosion resistance of aluminum sheets. These coatings chemically react with the surface to create a protective layer that inhibits corrosion. It is important to consider the specific requirements and environmental conditions when choosing a method of surface protection for outdoor aluminum sheets. Each method has its own advantages and limitations, and the choice should be based on factors such as durability, appearance, cost, and maintenance requirements.

- I was watching an old Star Trek movie. The last one with the full original cast; where they bring two whales into the future. There is a scene in which Scotty and Bones are trying to get material to build a giant tank to hold the whales inside the Klingon space ship. They go to a manufacturer and offer him the formula for Clear Aluminum in exchange for the materials. Scotty and Bones don't know who invented Clear Aluminum and the manufacturer who will eventually place the patent in the 20th century didn't really invent it, so who did? If you think of this as a thought experiment would this prove that other universes exist? Did Scotty and Bones create a new universe?

- Nichols was eventually recognized as the inventor of transparent aluminum.

- To store aluminum sheets, it is important to consider their size, weight, and overall condition. Here are some steps you can follow: 1. Choose a suitable location: Find a dry and well-ventilated area with stable temperatures, preferably indoors. This will help prevent moisture and humidity from causing corrosion or damage to the aluminum sheets. 2. Protect against moisture: Use plastic or moisture-resistant sheets to wrap each aluminum sheet individually. This will create a barrier against moisture and prevent any potential corrosion. Avoid using materials that may react with aluminum, such as acidic or alkaline substances. 3. Organize and stack: If you have multiple aluminum sheets, consider organizing them based on their size, thickness, or other relevant factors. This will make it easier to access specific sheets without disturbing the entire stack. When stacking the sheets, place larger and heavier ones at the bottom to avoid any potential damage. 4. Utilize racks or pallets: If you have a larger quantity of aluminum sheets, using racks or pallets can provide additional support and stability. Ensure the racks or pallets are strong enough to handle the weight and are designed to prevent any deformation or bending of the sheets. 5. Label and document: It is helpful to label each sheet with relevant information such as size, thickness, or any specific details. Additionally, keeping a detailed inventory or catalog of your aluminum sheets can help you easily locate and retrieve specific ones when needed. 6. Regular inspection: Periodically inspect your stored aluminum sheets to ensure they remain in good condition. Look for signs of corrosion, damage, or any other issues that may require immediate attention. By following these steps, you can effectively store aluminum sheets, protecting them from damage and ensuring their longevity.

- There are several strategies you can use to prevent fingerprints on aluminum sheets: 1. Opt for gloves: To avoid leaving fingerprints on aluminum sheets, a simple solution is to wear gloves while handling them. This creates a barrier between your hands and the surface, preventing any marks or smudges. 2. Thoroughly clean the surface: Before touching aluminum sheets, ensure that the surface is clean. Use a suitable cleaning agent or mild detergent to remove any dirt or oils. Dry the sheets completely with a lint-free cloth to minimize the chances of fingerprints sticking to the surface. 3. Apply a protective coating: Prevent fingerprints by applying a protective coating on the aluminum sheets. Clear lacquer or a clear protective film designed for this purpose are viable options. These coatings create a barrier that reduces the visibility of fingerprints and makes them easier to clean off. 4. Handle with care: Minimize direct contact with aluminum sheets to reduce the likelihood of fingerprints. Fingerprints are more likely to occur when pressure is applied or when the surface is repeatedly touched. Whenever possible, use tools or gloves to manipulate the sheets instead. 5. Proper storage: Ensure that aluminum sheets are stored in a clean and dust-free environment, away from potential contaminants. Consider using protective sleeves or covers to shield the sheets from fingerprints and other marks. By implementing these preventive measures, you can significantly decrease the occurrence of fingerprints on aluminum sheets, maintaining their cleanliness and visual appeal.

- If you want to prevent scratches on aluminum sheets, there are several measures you can take: 1. Be cautious when handling: Always keep in mind that aluminum sheets are susceptible to scratches. Avoid dragging or sliding them on rough surfaces, as this can cause scratches. Instead, lift and place them gently on a clean and smooth surface. 2. Use protective coverings: Consider using plastic film or paper to cover aluminum sheets before storing or transporting them. These coverings act as a barrier and prevent direct contact with other surfaces, reducing the chances of scratches. Make sure the coverings are clean and free from dirt or debris. 3. Store in a safe environment: Store aluminum sheets in a clean and dry environment when they are not in use. Avoid storing them with abrasive materials or objects that may scratch them. You can also use dividers or separators to create individual compartments for each sheet, preventing them from rubbing against each other. 4. Clean with care: Use a soft cloth or sponge that is non-abrasive when cleaning aluminum sheets. Avoid using wire brushes or rough materials that can cause scratches. Additionally, use a mild detergent or aluminum cleaner specifically designed for this purpose. Rinse the sheets thoroughly and dry them completely to prevent any moisture-related damage. 5. Apply a protective coating: Another option to protect aluminum sheets from scratches is to apply a protective coating. There are various types of coatings available, such as clear lacquers or specialized aluminum protectants. These coatings create a thin barrier on the surface of the aluminum, providing an extra layer of protection against scratches. By following these steps, you can significantly minimize the risk of scratches on your aluminum sheets and preserve their appearance and integrity over time.