Aluminium Square Tube

Aluminium Square Tube Related Searches

1 Inch Aluminum Square Stock 3 4 Aluminum Square Stock 6063 Aluminum Round Bar Stock Fiberglass Pipe Shaver Pipe Scaffolding Aluminum Solid Square Stock 6063 T6 Aluminum Plate Square Aluminum Stock Aluminum Plate 6063 Polypropylene Pipe Size ChartHot Searches

Aluminum Square Stock For Sale Fiberglass Scaffolding For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale White Gazebo For Sale White Melamine Board Price Frp Price Per Square Foot Ceiling Fan Lowest Price Plywood Per Square Foot Price Cost Of Plywood Per Square Metre Aluminum Square Stock Near Me Cost Of Mdf Per Square Metre White Plastic Folding Chairs Wholesale Geotextile Fabric Cost Per Square Foot Frp Cost Per Square Foot Plywood Cost Per Square Meter Asphalt Shingle Prices Per Square Aluminium Wire Mesh Manufacturers India Ceiling Fan Lowest Price Aluminium Scaffold Planks SaleAluminium Square Tube Supplier & Manufacturer from China

Okorder.com is a professional Aluminium Square Tube supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Aluminium Square Tube firm in China.Hot Products

FAQ

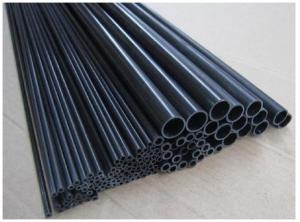

- The maximum temperature that aluminum pipes can withstand depends on several factors, including the specific alloy of aluminum used and the intended application of the pipes. Generally, aluminum pipes can withstand temperatures up to around 400-600 degrees Fahrenheit (200-315 degrees Celsius) without significant deformation or failure. However, it is important to note that prolonged exposure to high temperatures can weaken the material and potentially lead to failure. Therefore, it is crucial to consult the manufacturer's specifications and guidelines to determine the exact maximum temperature limit for a particular aluminum pipe.

- The aluminum pipe in the fridge is leaking. What should I do to fill it up?

- With good brothers gluing, 1; polished by voile. 2; with good brothers glued on the line, remember a few times glue.

- How do you weld aluminum plate and aluminium tube?

- Hello, aluminum tube and aluminum welding is a kind of special operation and the special process, you can use WEWELDING53 low temperature aluminum welding wire, welding aluminum base metal materials in any temperature 380-400 degrees under, and not with the solder powder, which makes the new welding aluminum have become very easy, and if it is thin pieces or small pieces of aluminum welding, with porous spray burn gas welding, can prevent the collapse of the parent material, can better control the deformation of aluminum.

- Several factors can influence the lifespan of aluminum pipes, such as material quality, usage conditions, and maintenance practices. On average, these pipes typically endure for 20 to 50 years. This longevity is attributed to aluminum's exceptional resistance to corrosion, which effectively prevents rust and other forms of deterioration. Moreover, aluminum pipes are renowned for their lightweight and durable nature, making them suitable for a wide range of applications. By ensuring proper care and conducting regular inspections, these pipes can reliably perform for many decades, offering long-lasting service.

- Yes, aluminum pipes are generally resistant to impact damage due to their high strength-to-weight ratio and inherent durability. However, the extent of resistance may vary depending on factors such as pipe thickness, alloy composition, and the force of impact.

- How to weld the refrigerator aluminum tube?

- Flame brazing of aluminium tube for refrigerator.Because the refrigerator aluminum tubes are relatively small, relatively thin, and more used for copper tube, aluminum pipe or aluminum pipe copper pipe welding, of course, there are aluminum pipe, aluminum pipe welding. From the above three situations, can be divided into the following welding methods1, if it is aluminum brass or brass tubes connected, can choose Wei Odin copper aluminium welding rod flame brazing welding, the welding work at the melting point of 480 degrees, is cored electrode without the use of complex welding powder.2, if it is connected to the aluminum tubes, aluminum welding can be used WEWELDING Q303, with no need to use liquefied petroleum gas spray welding powder, heating WE53 special welding parts to 500 degrees, and then use the wire in welding parts with a wire tip forming flame burn slightly. Can also use ordinary ER4047 aluminum wire with aluminum powder to WE53-F welding, the welding cost is relatively low, but the technique requirements are relatively high. For expert use.

- What are the specifications of aluminium tubes?

- Shanghai pan bamboo company specializing in the production of aluminum pipe, thin-walled tubes, thick walled tubes, small diameter tubes, large diameter tubes, small caliber thin-walled tubes, small caliber thick wall pipe, large diameter thin-walled aluminum tube, large diameter thick walled tubes, various specifications of aluminum rodNo specifications can be customized to find Ke Chunquan Oh, I hope to help you oh!

- Aluminum pipes have shown good performance in seismic zones due to their inherent characteristics of being lightweight and flexible. These properties allow them to absorb and dissipate seismic energy, reducing the risk of structural damage or failure. Additionally, aluminum pipes have high ductility, enabling them to withstand ground movements during earthquakes without experiencing significant deformation or rupture. Overall, aluminum pipes are considered a reliable choice for use in seismic zones.