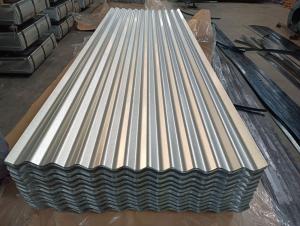

4X8 Galvanized Sheet Metal

4X8 Galvanized Sheet Metal Related Searches

Best Paint For Stainless Steel Paint For Galvanized Steel Steel Frames For Furniture Self Tapping Screws For Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For Bbq Step Bit For Stainless Steel Sponge For Stainless SteelHot Searches

Used Metal Folding Chairs For Sale Large Metal Containers For Sale Metal Shop Cabinets For Sale Metal Shipping Crates For Sale Galvanized Steel Scrap Price Fiber Sheet Price In India Galvanized Steel Prices Plastic Fiber Sheet Price Upvc Roofing Sheet Manufacturer In India China Geomembrane Roll Sheet Lasani Wood Sheet Price Rhino Roofing Sheet Price List Tinplate Sheet Price Mdf Price Per Sheet 4Mm Mdf Sheet 1220X2440Mm Price Grp Sheet Price Aluminum Sheet Stock Sizes Cost Of 4X8 Sheet Of Plywood Cost Of Drywall Per Sheet Buy Sheet Plastic4X8 Galvanized Sheet Metal Supplier & Manufacturer from China

Okorder.com is a professional 4X8 Galvanized Sheet Metal supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest 4X8 Galvanized Sheet Metal firm in China.Hot Products

FAQ

- What is steel concrete?

- The steel reinforced concrete structure for steel reinforced concrete in Japan (two, u, iron and iron bars, a}) structure. In Europe and the United States known as the concrete steel structure (SteelEnc, ED, Concrete) structure, in the former Soviet Union is known as the reinforced concrete structure. According to different forms of steel distribution, SRC structures can be divided into two types: solid steel, steel reinforced concrete and seamless steel reinforced concrete. At present, the solid steel reinforced concrete members are often used in seismic structures, and the typical section forms of solid steel concrete columns, beams, shear walls and joints are commonly used.

- There are several methods of protecting steel sheets from scratches, including applying a protective coating such as paint or powder coating, using adhesive films or tapes, using protective sleeves or covers, and implementing proper handling and storage practices to minimize contact with abrasive surfaces.

- There are several advantages to using steel sheets instead of materials like aluminum or copper. Firstly, steel is known for its exceptional strength and durability, making it able to withstand heavy loads and resist impacts better than aluminum or copper. This makes steel sheets perfect for applications that require high strength and structural integrity, such as in construction or the automotive industry. Furthermore, steel sheets have a higher melting point than aluminum or copper, meaning they can withstand higher temperatures without deforming or melting. This makes steel sheets suitable for applications that involve exposure to high temperatures, like in manufacturing processes or engine components. Additionally, steel sheets have excellent corrosion resistance properties. They can be coated with protective layers like zinc or chromium to enhance their resistance to rust and corrosion. In contrast, aluminum and copper are more prone to corrosion, especially when exposed to certain environments or chemicals. This makes steel sheets the preferred choice for outdoor applications or structures that need long-term durability. Another advantage of steel sheets is their cost-effectiveness. Steel is relatively cheaper compared to aluminum or copper, especially when considering its strength and durability. This makes steel sheets a more economical choice for various applications where cost is an important factor. However, it is important to note that aluminum and copper also have their own advantages. Aluminum is lightweight and has excellent thermal conductivity, making it suitable for applications that require lightweight materials or efficient heat transfer. Copper, on the other hand, has superior electrical conductivity, making it ideal for electrical wiring or components. In conclusion, steel sheets offer exceptional strength, durability, corrosion resistance, and cost-effectiveness compared to aluminum or copper. However, the choice of material ultimately depends on the specific requirements of the application, such as weight, thermal or electrical conductivity, and environmental factors.

- Yes, steel sheets are a suitable option for interior wall cladding. They are durable, fire-resistant, and provide a modern and sleek aesthetic. Steel sheets can be easily installed and offer excellent protection against moisture, making them a popular choice for high-traffic areas such as kitchens and bathrooms. Additionally, steel sheets can be customized in terms of color, texture, and finish, allowing for versatile design possibilities.

- The average lifespan of steel sheets can vary depending on various factors such as the quality of the steel, the environment it is exposed to, and the level of maintenance. However, on average, steel sheets can last anywhere from 20 to 30 years or even longer with proper care and maintenance.

- Yes, steel sheets can be used for electrical transformers. Steel is often used as the core material in transformers due to its magnetic properties and ability to efficiently conduct magnetic flux.

- HRPO and HRSPO are both types of steel sheets, but they differ in their manufacturing process and resulting properties. HRPO stands for Hot Rolled Pickled and Oiled, while HRSPO stands for Hot Rolled Skin Passed and Oiled. The HRPO steel sheet is made by subjecting a hot rolled steel coil to a pickling process, which involves removing impurities and scale from the surface using an acid bath. After pickling, the steel sheet is then oiled to prevent corrosion during storage and transportation. This process results in a smooth and clean surface finish. On the other hand, the HRSPO steel sheet undergoes an additional skin pass process after pickling and oiling. During the skin pass process, the steel sheet is passed through a set of rolls to improve the surface finish and reduce its thickness. This process also imparts a certain level of cold work to the steel, enhancing its mechanical properties. In terms of properties, HRPO steel sheets exhibit good formability, weldability, and paintability due to their clean surface and lack of scale. They are commonly used in applications that require a smooth surface finish, such as appliances, automotive parts, and exposed architectural components. HRSPO steel sheets, with their improved surface finish and reduced thickness, offer even better formability and surface quality compared to HRPO sheets. They are often used in more demanding applications where precise dimensional control and surface aesthetics are crucial, such as automotive body panels, electrical enclosures, and furniture manufacturing. In summary, the main difference between HRPO and HRSPO steel sheets lies in the additional skin pass process that HRSPO undergoes, resulting in improved surface finish, reduced thickness, and enhanced mechanical properties. The choice between the two depends on the specific requirements of the application in terms of surface quality, dimensional control, and mechanical performance.

- The maximum width of a steel sheet can vary depending on various factors such as the manufacturing process, equipment capabilities, and industry standards. In general, steel sheets can be produced in widths ranging from a few inches to several feet. However, in certain specialized applications, wider steel sheets exceeding 100 inches or more may be available. It is best to consult with steel manufacturers or suppliers to determine the maximum width options they offer, as it can vary depending on the specific requirements and capabilities of the production facility.