400 Series Stainless Steel

400 Series Stainless Steel Related Searches

Best Paint For Stainless Steel Blanket Insulation For Steel Buildings Primer For Galvanized Steel Foam Filter For Stainless Steel H S Code For Stainless Steel Surface Grinding Wheels For Stainless Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For BbqHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Used Solar Inverter For Sale Steel Mesh Panels For Sale400 Series Stainless Steel Supplier & Manufacturer from China

Okorder.com is a professional 400 Series Stainless Steel supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest 400 Series Stainless Steel firm in China.Hot Products

FAQ

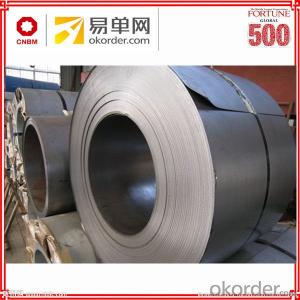

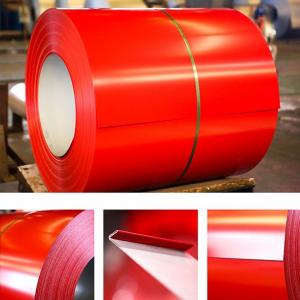

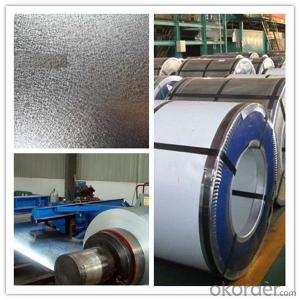

- Steel coils can undergo various surface treatment methods, each with its own advantages and uses. Some commonly employed techniques include: 1. Hot-dip galvanizing: Immersing the steel coil in molten zinc results in a protective coating. This process offers excellent corrosion resistance and is commonly employed in outdoor applications like roofing, fencing, and automotive parts. 2. Electro-galvanizing: A thin layer of zinc is electroplated onto the steel coil's surface. Electro-galvanizing provides similar corrosion resistance to hot-dip galvanizing but with a thinner coating. It is often utilized when a smooth and visually appealing finish is desired, such as in appliances, electrical equipment, and automotive components. 3. Powder coating: A dry powder is applied to the steel coil's surface and cured under heat to form a durable and protective layer. This method offers excellent resistance to chipping, scratching, and fading, making it suitable for both indoor and outdoor applications. 4. Painting: Liquid paint coatings can be applied to steel coils, offering both protection and aesthetic appeal. These coatings can be customized to meet specific requirements such as corrosion resistance, UV protection, or chemical resistance. They find common usage in industries like construction, automotive, and appliances. 5. Pickling and oiling: This method involves removing scale or rust from the steel coil's surface by dipping it in an acid solution (pickling), followed by a coating of oil to prevent reoxidation. Pickling and oiling are typically employed for temporary corrosion protection during the storage and transportation of steel coils. 6. Pre-painted coatings: Steel coils can be coated with pre-painted finishes during the manufacturing stage. This continuous process involves passing the steel coil through a coating line where a layer of paint is applied. Pre-painted coatings offer a wide range of colors and finishes, making them popular in industries like construction, automotive, and appliances. These are only a few examples of the surface treatment methods commonly used for steel coils. The selection of a specific technique depends on factors such as desired corrosion resistance, aesthetic preferences, environmental conditions, and specific application requirements.

- Yes, steel coils can be customized in terms of size and specifications. Manufacturers have the ability to produce steel coils in various sizes and specifications to meet the specific requirements and needs of different industries and applications. This customization allows for greater flexibility and ensures that the steel coils can be used efficiently in different processes.

- Steel coils are used in various industries for a wide range of applications. In the automotive industry, they are used to manufacture car bodies, chassis, and parts. In construction, steel coils are used in the production of beams, columns, and roofing materials. They are also utilized in the manufacturing of appliances, electrical equipment, and machinery. Additionally, steel coils are essential in the production of pipes, tubes, and other structural components. Overall, steel coils play a crucial role in providing strength, durability, and versatility to multiple industries.

- I need help my new stainless steel cookware is sticking ? My first meal was nasty!

- You sure it's stainless steel? Quick test, is to put a magnet to it. Stainless steel won't stick to a magnet,Sorry your meal turned out icky. Bye

- Steel coils are commonly used in the production of prefabricated buildings as they are rolled into sheets and cut into specific lengths to create the structural components such as beams, columns, and frames. These steel components provide strength, stability, and durability to the prefabricated building, making it capable of withstanding various environmental and structural loads.

- The cost of a steel coil can vary depending on several factors such as the type of steel, size, weight, and market conditions. It is best to contact a steel supplier or manufacturer for an accurate and up-to-date price quote.

- Steel coils are used in the production of structural components as they serve as the primary raw material for various manufacturing processes. These coils are typically processed through rolling mills, where they are heated, shaped, and transformed into different structural shapes, such as beams, columns, and plates. The high strength and durability of steel make it an ideal choice for constructing buildings, bridges, and other infrastructure, ensuring the structural integrity and longevity of these components.

- I need details for steel column splices welded or bolted. References or autocad blocks will be very useful. Thank you very much!

- The refernce for Canada is S16-01 Limit states steel design My professor always taugth us shop weld field bolt if that helps