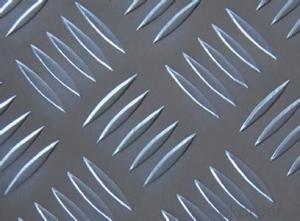

3 16 Checkered Plate

3 16 Checkered Plate Related Searches

Thickness Of Checkered Plate Stainless Checkered Plate Insulation Plate Cheap Checkered Plate Astm A786 Checkered Plate Diamond Checkered Plate Ss Checkered Plate A786 Checkered PlateHot Searches

Lasani Wood Sheet Price Aluminium Checkered Plate Price 4Mm Mdf Sheet 1220X2440Mm Price Aluminium Scaffold Planks Sale Buy Sheet Plastic Aluminium Walkway Mesh Prices 9Mm Mdf Sheet Prices Tinplate Sheet Suppliers Checkered Plate Standard Sizes Checkered Plate Suppliers Aluminium Checkered Plate Price Aluminium Walkway Mesh Prices Checkered Plate Standard Sizes Checkered Plate Suppliers Aluminium Checkered Plate Price Checkered Plate Standard Sizes Checkered Plate Suppliers3 16 Checkered Plate Supplier & Manufacturer from China

Okorder.com is a professional 3 16 Checkered Plate supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest 3 16 Checkered Plate firm in China.Hot Products

FAQ

- A smooth steel sheet has a flat and even surface, while a textured steel sheet has a pattern or texture imprinted on its surface, providing a visual or tactile effect.

- Yes, steel sheets are prone to warping or buckling under certain conditions such as high temperatures, uneven cooling, excessive load, or inadequate support. However, the degree of susceptibility depends on the thickness, quality, and type of steel used. Proper installation, handling, and maintenance can minimize the risk of warping or buckling in steel sheets.

- The typical elongation of a steel sheet varies depending on the specific grade and thickness of the sheet. However, on average, steel sheets can have an elongation of around 20-30% before they reach their breaking point.

- Indeed, automotive body panels can utilize steel sheets. The automotive industry often opts for steel as a material of choice owing to its robustness, resilience, and capacity to withstand impacts. Body panels frequently employ steel sheets because they confer structural integrity to vehicles and effectively safeguard occupants during collisions. Furthermore, steel can be effortlessly shaped and molded into intricate forms, rendering it ideal for designing diverse body panels. All in all, steel sheets are a dependable and frequently preferred option for automotive body panels.

- The use of steel sheets in various applications comes with several limitations. To begin with, steel sheets are considerably heavy compared to other materials, which can present challenges in terms of transportation and installation. This weight can also hinder their usage in industries like aerospace or automotive, where weight reduction is crucial. Secondly, steel sheets are prone to corrosion, particularly when exposed to moisture and chemicals. Without proper protection, this can lead to rusting and a decrease in structural integrity over time. Therefore, additional coatings or treatments are often necessary to prevent corrosion, which adds to the overall cost and maintenance requirements of using steel sheets. Another limitation is the limited flexibility of steel sheets, making it difficult to mold or shape them into complex forms. This restricts their application in areas where intricate designs or curved surfaces are needed, such as the construction of curved roofs or architectural structures. Furthermore, steel sheets have poor thermal insulation properties, meaning they conduct heat and cold more readily than other materials. This can result in temperature fluctuations and energy loss in buildings, necessitating additional insulation measures to maintain thermal comfort and energy efficiency. Lastly, steel sheets are a finite resource, and their production has a significant environmental impact. The extraction of raw materials, energy consumption, and carbon emissions associated with steel production make it less sustainable compared to alternative materials. In conclusion, while steel sheets are widely valued for their strength and durability, it is important to consider their limitations, including their weight, susceptibility to corrosion, limited flexibility, poor thermal insulation properties, and environmental impact, when selecting materials for specific applications.

- Indeed, it is possible to laminate steel sheets with different substances. Lamination involves the fusion of two or more materials to form a composite material that boasts improved characteristics. When it comes to steel sheets, they can be laminated with a variety of materials including plastics, polymers, wood, and even other metals. This technique is frequently employed to enhance the strength, longevity, resistance to corrosion, and visual appeal of steel sheets. Laminated steel sheets can be observed in numerous sectors such as automotive, construction, aerospace, and furniture production.

- Yes, steel sheets are suitable for interior door panels. They offer durability, strength, and can provide a sleek and modern aesthetic to interior spaces. Additionally, steel sheets can be easily customized and painted to match various interior design styles.

- What does steel plate "A3" mean?

- It can be used in all kinds of grinding tools, handles and other unimportant Abrasives parts