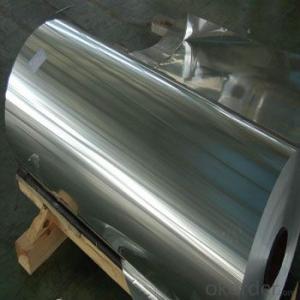

019 Aluminum Coil Stock

019 Aluminum Coil Stock Related Searches

Led Light Bulbs For Ceiling Fixtures Led Lamps For Ceiling 42 In Ceiling Fan With Light Aluminum Coil Stock For Gutters Aluminum Foil For The Grill Hole Saw For Aluminum Plate Aluminum Tread Plate For Trailer Bow Plate For Aluminum Boat Aluminum Foil For Grow Room Aluminum Foil For Joint PainHot Searches

Stock Price For Aluminum Aluminum Coil Stock For Sale Aluminum Gutter Coil For Sale Used Aluminum Scaffolding For Sale 1/4 Aluminum Plate For Sale Aluminum Bar Stock For Sale Aluminum Round Stock For Sale Aluminum Diamond Plate For Sale Aluminum Scaffolding For Sale Craigslist 6061 Aluminum Plate For Sale Aluminum Dock Plate For Sale 7075 Aluminum Plate For Sale Aluminum Tread Plate For Sale Aluminum Checker Plate For Sale Aluminum Plate For Sale Near Me Plate Aluminum For Sale Aluminum Plate For Sale Aluminum Square Stock For Sale Aluminum Flat Stock For Sale Billet Aluminum Stock For Sale019 Aluminum Coil Stock Supplier & Manufacturer from China

Okorder.com is a professional 019 Aluminum Coil Stock supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest 019 Aluminum Coil Stock firm in China.Hot Products

FAQ

- Yes, aluminum coils can be used in the production of aluminum composite ceilings. Aluminum coils are commonly used as the base material for manufacturing aluminum composite panels, which are then used in various applications including ceilings. The coils are processed and coated to meet the desired specifications and aesthetics of the composite ceiling panels.

- How to calculate the wall thickness with the gross weight of aluminum coil known?

- Gross weight*density=volume volume÷(aluminum sheet *width)=thickness

- Consider the following ionization energies for aluminum:Al(g) → Al+(g) + eI1 = 580 kJ/molAl+(g) → Al2+(g) + eI2 = 1815 kJ/molAl2+(g) → Al3+(g) + eI3 = 2740 kJ/molAl3+(g) → Al4+(g) + eI4 = 11,600 kJ/mol A) Account for the trend in the values of the ionization energies.B) Explain the large increase between I3 and I4.

- aluminum forms an ion by loosing electrons. once an electron is lost, the nucleus attains net positive charge. as a result, the remaining electrons are strongly held by nuclea force of attraction, hence more energy is required to remove them.

- Yes, aluminum coils can be used in the manufacturing of appliances. Aluminum coils offer several advantages such as being lightweight, corrosion-resistant, and having good thermal conductivity, making them suitable for various appliance applications including refrigerators, air conditioners, and heating systems.

- How to remove the fingerprint and glue residue on the color aluminum coil?

- Try to use essential balm. We often use the essential balm to remove glue residue on the stainless steel bowl and basin.

- Aluminum coils can be joined or welded using various methods depending on the specific application and desired outcome. Some common methods include: 1. Mechanical fastening: This involves using bolts, screws, or rivets to physically fasten the aluminum coils together. Mechanical fastening is a simple and cost-effective method, suitable for joining thin coils or for temporary connections. 2. Adhesive bonding: Adhesive bonding involves using specialized adhesives to bond aluminum coils together. This method provides a strong and durable joint, with the added advantage of distributing stress evenly across the entire bond area. Adhesive bonding is commonly used in applications where aesthetics, weight reduction, or vibration dampening are important considerations. 3. Resistance welding: Resistance welding utilizes an electric current to generate heat and pressure at the joint, effectively welding the aluminum coils together. This method is particularly suitable for high-speed production lines and can provide a strong and reliable joint. However, it requires specialized equipment and is not suitable for all types of aluminum alloys. 4. Laser welding: Laser welding is a precise and efficient method that uses a laser beam to melt and join the aluminum coils. This technique allows for precise control of heat input, resulting in minimal distortion and excellent weld quality. Laser welding is commonly used in industries where high precision and aesthetic appearance are crucial, such as automotive and aerospace. 5. Friction stir welding: Friction stir welding is a solid-state joining process that uses a rotating tool to generate heat and friction, effectively welding the aluminum coils together without melting the material. This method produces strong and high-quality welds with minimal distortion and no need for additional filler material. Friction stir welding is commonly used in industries where excellent mechanical properties and high productivity are required, such as shipbuilding and railway construction. Overall, the choice of joining or welding method for aluminum coils depends on factors such as the desired joint strength, application requirements, production volume, and available equipment and expertise.

- Yes, aluminum coils can be used for window frames. Aluminum is a popular choice for window frames due to its lightweight, durable, and corrosion-resistant properties. It is also easily customizable and can be painted or anodized to achieve different aesthetics.

- What happened to the aluminum coil coming out of the annealing furnace?

- There is oil on the aluminum coil and the annealing time is too long.