Woven Geotextile 200g m2 Non Woven Geotextile 300g m2

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Woven Geotextile 200g m2 Non Woven Geotextile 300g m2

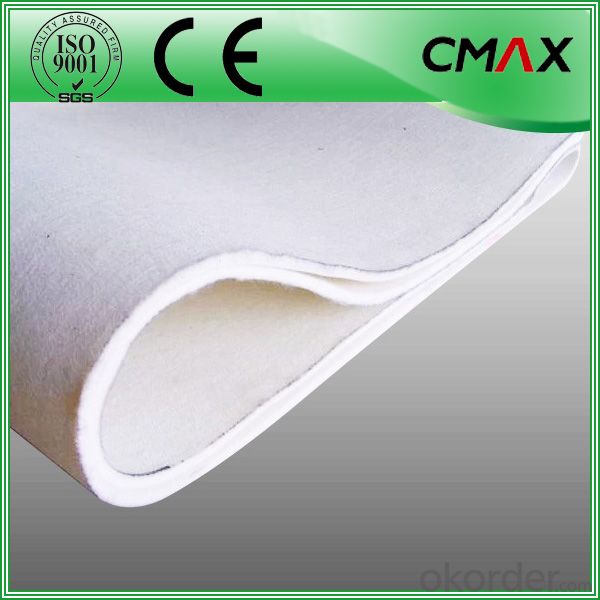

Desciriptions:

Non Woven Geotextile 300g m2 are the preferred products for lining projects requiring low permeability ,corrosion protection , exceptional chemical and ultraviolet resistance properties , which makes them extremely cost effective for many applications such as waste landfill , storage reservoirs ,canals , powr plants in energy ,

vapor barriersand waste water treatment in the line of industry and aquaculture and agriculture projects.

Specifications:

| Weight / Mass | 100gsm - 800gsm |

| width | Within 8 m |

| longth | 50-100m/roll (at request) |

| Material | PP / PET |

| Color | Black , white , grey |

| Certification | CE/ISO9001 |

| Manufacturing method | nonwoven / woven |

Characteristics:

Easy process and high output rates

Excellent distribution of carbon black

Consistent quality and low failure rate

Excellent resistance and good waterproof ability

Good welding

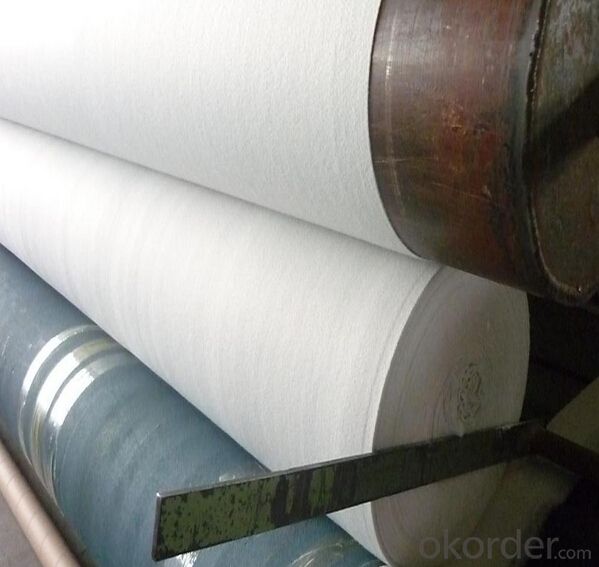

Details of our products:

Produce process:

Applications:

1) Filtration :

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation :

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle :

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection :

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Packing and shipping:

♦ Packing:in plastic film bag(keep away from moisture) and PP bag or as your customize.

♦ Shipping:By sea or as your customize

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

HDPE Geomembrane Price

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q:How do geotextiles help with erosion control on shorelines?

- Geotextiles help with erosion control on shorelines by acting as a barrier that prevents soil erosion while still allowing water to pass through. They stabilize the soil by trapping sediment and preventing it from being washed away by waves or currents. Additionally, geotextiles promote the growth of vegetation, which further helps to anchor the soil and reduce erosion.

- Q:How do geotextiles contribute to pavement design?

- Geotextiles play a crucial role in pavement design by providing various benefits. They help in enhancing the structural integrity of the pavement by distributing loads more uniformly, minimizing stress and preventing cracking. Geotextiles also act as a separator, preventing the mixing of subgrade soil with the overlying pavement layers. Additionally, they aid in filtration by allowing water to pass through and drain efficiently, preventing water buildup and potential damage. Overall, geotextiles contribute to the longevity and durability of pavements by improving their performance and reducing maintenance needs.

- Q:Are geotextiles suitable for use in geocell retaining walls?

- Yes, geotextiles are suitable for use in geocell retaining walls. Geotextiles are often used as a separation and filtration layer in geocell systems, helping to prevent soil erosion, improve drainage, and enhance overall stability of the retaining wall.

- Q:Can geotextiles be used in erosion control on riverbanks?

- Yes, geotextiles can be used in erosion control on riverbanks. Geotextiles are often used as a stabilization measure to prevent soil erosion by providing a barrier against water flow and supporting vegetation growth. They help to retain soil while allowing water to pass through, reducing the impact of flowing water on riverbanks and preventing further erosion.

- Q:Can geotextiles be used for livestock waste management?

- Yes, geotextiles can be used for livestock waste management. They are commonly used as liners in lagoons or ponds to separate and contain livestock waste, preventing it from contaminating groundwater or nearby water bodies. Geotextiles can effectively filter and separate solid waste from liquid, allowing for proper waste management and reducing environmental impacts.

- Q:How are geotextiles tested for filtration efficiency?

- Geotextiles are typically tested for filtration efficiency using standardized laboratory tests such as the ASTM D4491 test method. This method involves measuring the flow rate of water through the geotextile under specific pressure conditions and determining the percentage of particles retained by the fabric. Other tests may also be conducted to assess the geotextile's ability to retain soil particles and prevent clogging.

- Q:How do geotextiles contribute to groundwater recharge?

- Geotextiles contribute to groundwater recharge by acting as a permeable barrier that allows water to infiltrate the soil while preventing soil erosion. This helps to retain and replenish groundwater levels by promoting the natural process of water percolation and recharge into aquifers.

- Q:What are the primary applications of geotextiles?

- Geotextiles are primarily used in civil engineering and construction projects for applications such as soil stabilization, erosion control, filtration, drainage, and reinforcement of soils. They can also be used in environmental projects, agriculture, and transportation infrastructure.

- Q:Can geotextiles be used in agricultural drainage systems?

- Yes, geotextiles can be used in agricultural drainage systems. They are commonly used as a filter fabric to prevent soil particles from clogging drainage pipes while allowing water to pass through. Geotextiles help improve the efficiency and longevity of agricultural drainage systems by preventing soil erosion and maintaining the proper flow of water.

- Q:Does geotextile affect water purification?

- Do not know what you use after the purification of water, if not drinking water, I think it will not affect the water quality, the general purpose of water purification, geotextile will not affect, because the geotextile material is polyester or polypropylene, In the chemical nature of relatively stable, no changes in room temperature conditions, so there will not be any impact on water quality

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Woven Geotextile 200g m2 Non Woven Geotextile 300g m2

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords