Wood Grain Color Melamine Faced MDF for Furniture

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Wood Grain Color Melamine MDF Board

General Information:

Wood Grain colors of home decoration and kitchen cabinet. It is a rich option of colors and it is a popuplar material for making furniture and decoration.

Features:

Eco-friendly

impact resistance

stable dimension.

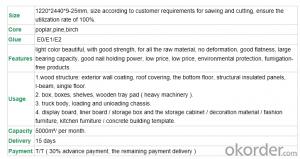

Specification:

Material: Melamine impreged paper and MDF board

Glue: E1 E2

size of 1220x2440mm

thickness: from 2mm to 25mm

Moisture Content: 7-10%

Certificate: ISO 9001

Minimum: 50m3

Photos:

FAQ:

① why from okorder?

Okorder is a qualified supplier of all kinds of building matierials in China. All products have been showed in Okorder website are under well controlled by okorder QC team.

All products had been produced under a clear quality standard and the quality is consistence among the shipments.

Okorder has already setted up more than 20 warehouses in different markets to show the products. You are convenient to know the products from your local place and it will help you to make decision easyly.

②How to guarantee the quality of the products?

We have established a perfect quality management system,as for raw material and semi parts all are under strict quality test and we have a IQC system to control the purchases.

QC on site is very strict and all steps of process are measured per drawings. Before delivery, we set a OQC system to make sure each piece meet the standard of order.from design to delivery,

③How long can we receive the product after purchase?

Lead time depending on order quanity, The normal order can be deliveried with 3 weeks.

- Q:Particleboard production process requires proper hot pressing pressure

- Hot mold can be used less rubber or rubber, by lignin in the closed hot mold activation flow from the glue, but need to cooling stripping, heat consumption, low productivity, has been gradually eliminated

- Q:How to improve the particleboard market space

- In order to improve the quality of the particleboard and reduce the cost and improve the research and development capabilities

- Q:Particleboard production requires proper moisture content

- According to the different density requirements of products, hot pressing pressure is generally 1.2 to 1.4 MPa.

- Q:What types of particleboard can be divided into?

- the nature of the process can be machinable, can be glued, paint finish and so on

- Q:According to the use of points: Class A particleboard; Class B particleboard

- According to the use of raw materials: wood particleboard; bagasseboard particleboard; linseed particle board; cotton stalk particle board; bamboo particle board; cement particle board; gypsum particleboard.

- Q:Market foreground and Industry development

- Particleboard due to poor quality and some other reasons, the market abandoned, many particleboard enterprises learn from the introduction of foreign advanced production lines and improve the level of technology,

- Q:Production of raw materials for particleboard

- Wood raw materials are taken from the forest cuttings, small diameter timber (usually less than 8 cm in diameter), harvesting residues and wood processing residues

- Q:Today's demand for wood-based panel products

- which gave the development of China's particleboard industry opportunities The Therefore, China's particleboard consumption is expected to increase year by year.

- Q:From the appearance point of view

- the length is generally 5-10MM length is appropriate, too long structure loose, too short anti-deformation of the poor, the so-called static bending strength is not compliance;

- Q:What create an excellent condition.

- Many furniture manufacturers have re-use of particleboard as raw materials, in addition, directional particleboard is also gradually accepted by consumers

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wood Grain Color Melamine Faced MDF for Furniture

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords