Tinplate For Seafood Can-CHBB

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Tons~ 25 Tons m.t.

- Supply Capability:

- 40000 MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General information of Tinplate For Seafood Can

|

Steel Type |

MR |

|

Temper (BA&CA) |

T1~T5, DR8 |

|

Coating |

2.8~8.4g/m2 |

|

Thickness & Tolerance |

0.15~0.5mm (Tolerance:±0.01mm) |

|

Width & Tolerance |

600~1000 mm(Tolerance: +2/-0mm) |

|

I.D |

508 MM |

|

Coil Weight |

3~10 MT |

|

Passivation |

311 |

|

Oiling |

DOS |

|

Surface Finish |

Bright ,Stone ,Silver ,Matte |

|

Min Order |

25 Tons for 1 20 feet FCL |

|

Package |

Seaworthy Export Standard Wooden Pallet |

|

Standard Available |

GB/T2520-2000, JIS G3303, ASTM A623, BS EN10202 |

|

Lead Time |

35 days after receiving buyer's original L/C or Prepayment |

|

Special specifications are available on customers' requirements. | |

Technical data of Tinplate For Seafood Can

|

Chemical Composition(%) |

Mechanical Property |

|

C:0.02~0.05 |

Yield Strength: (Mpa):280~320 |

|

Si:0.01~0.03 |

TensileStrength: (Mpa):340~390 |

|

Mn:0.18~0.22 |

Elongation:20%~30% |

|

P:0.014~0.016 |

------------- |

|

S:0.006~0.009 |

Application of Tinplate For Seafood Can

Tinplate is widely used for making all types of containers such as artistic cans, tea cans, painting cans,

chemical package cans and metal printing etc. Its applications are not limited to containers; recently,

tinplate has also been used for making electrical machinery parts and many other products.

Equipment and Facility of Tinplate

Tin Coating Line of Tinplate

Cold Rolling Mill Batch Annealing Furnaces

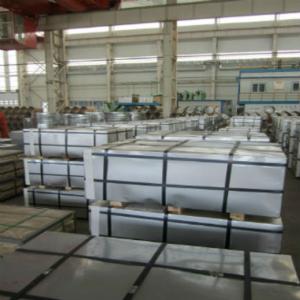

Cutting Line Stock Area

Quantity Control System of Tinplate

- Q:How is tinplate coated with protective lacquer?

- Tinplate is coated with protective lacquer by first cleaning and pre-treating the surface to remove any contaminants. Then, a thin layer of lacquer is applied onto the tinplate using various methods such as roller-coating or spray-coating. The lacquer acts as a barrier, protecting the tinplate from corrosion, oxidation, and other external factors that may affect its quality and durability.

- Q:How does tinplate contribute to the presentation of jewelry?

- Tinplate is often used in the packaging of jewelry, such as boxes or containers, which enhances the presentation and adds an element of luxury. Its glossy and reflective surface provides a visually appealing backdrop for showcasing the beauty and intricacy of the jewelry inside. Additionally, tinplate offers excellent protection against corrosion and moisture, ensuring the longevity and preservation of the jewelry.

- Q:Is tinplate recyclable?

- Yes, tinplate is recyclable.

- Q:How does tinplate affect the overall cost of packaging?

- Tinplate can impact the overall cost of packaging due to its higher production and material costs compared to other packaging materials. However, it offers several advantages such as durability, protection against moisture and oxygen, and aesthetic appeal, which may justify the additional expenses for certain products.

- Q:What are the common challenges in recycling tinplate packaging?

- Some common challenges in recycling tinplate packaging include contamination from other materials, such as paper or plastic, which can make the recycling process more difficult and less efficient. Additionally, tinplate packaging often contains a plastic lining or coating, which must be removed before recycling the tinplate itself. Another challenge is that tinplate packaging is often small and lightweight, making it more prone to being lost or mixed in with other waste streams. Finally, there may be limited infrastructure or collection systems in place to effectively collect and recycle tinplate packaging.

- Q:What are the main suppliers of tinplate?

- The main suppliers of tinplate are countries like China, Japan, South Korea, Germany, and the United States.

- Q:Can tinplate be used for confectionery packaging?

- Yes, tinplate can be used for confectionery packaging. Tinplate is a type of steel coated with a thin layer of tin, making it a durable and food-safe material. It provides excellent protection against moisture, light, and oxygen, which are important for maintaining the freshness and quality of confectionery products. Additionally, tinplate can be easily shaped and decorated, allowing for attractive and customized packaging designs.

- Q:What are the advantages of using tinplate for aerosol cans?

- Some advantages of using tinplate for aerosol cans include its durability, corrosion resistance, and ability to maintain product quality. Tinplate cans offer a longer shelf life for aerosol products as they prevent air and moisture from entering the can, ensuring the product remains fresh and effective. Additionally, tinplate cans are lightweight, making them convenient for transportation and storage. They are also recyclable, contributing to sustainability efforts.

- Q:How is tinplate used in the confectionery industry?

- Tinplate is commonly used in the confectionery industry for packaging purposes. It is used to make tin cans or containers that preserve and protect various confectionery products such as chocolates, candies, and biscuits. Tinplate offers excellent barrier properties against moisture, light, and oxygen, ensuring the quality and freshness of the confectionery items. Additionally, it provides a visually appealing and customizable packaging solution, making it popular in the confectionery industry.

- Q:Can tinplate be used for automotive components?

- Yes, tinplate can be used for automotive components. Tinplate offers good corrosion resistance and durability, making it suitable for various automotive applications such as fuel tanks, exhaust systems, and body parts. Additionally, tinplate's malleability allows for complex shapes and designs to be formed, further enhancing its usability in the automotive industry.

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei,China |

| Year Established | 2009 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe Domestic Market |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | TIANJIN |

| Export Percentage | 11% - 20% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | |

| Product Price Range | Average |

Send your message to us

Tinplate For Seafood Can-CHBB

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Tons~ 25 Tons m.t.

- Supply Capability:

- 40000 MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords