Steel Wire Rods Hot Rolled Low Carbon Prime Quality Best Selling

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Wire Rod Steel for Construction Description

Wire rod steel is widely used for commercial building structure, pre-engineering buildings, machinery support structures, prefabricated structure, medium scale bridges and so on. We have supplied this product for many years and gained widespread reputation.

2.Main Features of the Wire Rod Steel for Construction

fasteners, bolts, rivets, screws,

general purpose wires,

electrode wires, industrial wires, agriculture wires,

bush wires, chain rivet wires,

detonator wire,

Umbrella ribs, upholstery wires, cycle spokes, needle wires, heald wires, staple pin Wire, safety pin wires

ACSR wires, earth wires,

tyre and hose reinforcement wires,

prestressed concrete wire, springs and rope wires,

card clothing wires,

vineyard wires,

ball bearing quality

Automobile parts like screw, fasteners, bush, spline, socket, connecting rod, shaft, gear, rivets, engine shaft, connecting rod, spindles, gears, etc.

3.Wire Rod Steel for Construction Images

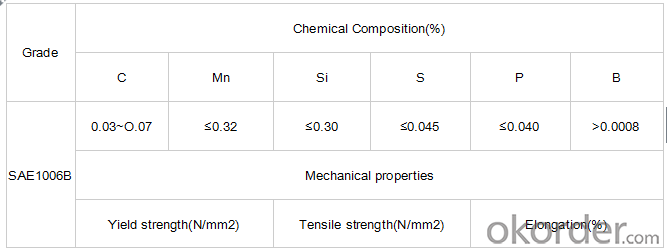

4.Wire Rod Steel for Construction Specification

5.FAQ of Wire Rod Steel for Construction

We have organized several common questions for our clients,may help you sincerely:

1.What is your minimum order quantity ?

Our MOQ is 500mt for each size. And we will consider to give more discount if you make big order like 10000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2.Please tell me the daily output and wire rod mill’s brand ?

Our daily output is 4000mt/day and our rolling mill from Germany’s SMS MEER

3.Which countries are your main sales?

Thanks to the professional international trade team, solid distribution channel and long – term cooperation customers, our market share in overseas realizes a tremendous growth, now we already became a main player in Middle East and South East Asia. Meanwhile, we are also the biggest supplier of Pre-painted galvanized steel coil in Philippines, Saudi Arabia, United Arab Emirates, Iran, Sudan etc.

- Q:What are the common industry best practices for steel wire rod suppliers?

- Some common industry best practices for steel wire rod suppliers include maintaining a high level of product quality, conducting regular quality checks and tests, adhering to international standards and certifications, delivering products on time and as per customer specifications, providing excellent customer service and support, offering competitive pricing, promoting sustainability and environmental responsibility in production processes, and continuously investing in research and development to improve product performance and efficiency.

- Q:What are the different types of packaging options available for steel wire rod?

- The packaging options for steel wire rod vary, depending on factors such as size, weight, intended use, and buyer or manufacturer preferences. Coil packaging is a common option for smaller diameter wire rods. It involves coiling the wire rod into a circular shape and tightly securing it with plastic or steel straps. Coils are convenient for transportation and storage. Bundle packaging, on the other hand, is suitable for larger diameter wire rods. This method involves bundling multiple pieces of wire rod together and tightly binding them with steel straps. Bundles provide stability during transportation and handling. In addition to coils and bundles, steel wire rod can also be packaged in wooden crates or pallets. This method offers extra protection during transportation and is suitable for both small and large diameter wire rods. Wooden packaging is often preferred for long-distance shipping or extended storage. Furthermore, manufacturers may offer custom packaging options to meet specific requirements. This could involve using special wrapping materials, implementing additional protective measures, or creating unique packaging designs. Overall, the various packaging options available for steel wire rod ensure safe and efficient handling, transportation, and storage, while also catering to the specific needs of buyers and manufacturers.

- Q:How does the magnetic properties of steel wire rod vary with different heat treatment processes?

- The magnetic properties of steel wire rod can greatly differ depending on the heat treatment processes used. Heat treatment involves subjecting the rod to controlled heating and cooling to change its microstructure, which in turn affects its magnetic properties. One commonly used heat treatment process for steel wire rod is annealing. Annealing involves heating the rod to a specific temperature and then slowly cooling it to room temperature. This process helps relieve internal stresses, refine the grain structure, and enhance the ductility of the wire rod. In terms of magnetic properties, annealing decreases the magnetic permeability of the rod, making it less vulnerable to magnetic fields. This can be advantageous in applications where minimizing magnetic interference is important. Another heat treatment process for steel wire rod is quenching and tempering. Quenching involves rapidly cooling the wire rod from a high temperature to room temperature, usually by immersing it in a quenching medium like oil or water. This rapid cooling results in a hard and brittle structure called martensite. However, martensite is not magnetic and has low ductility. To improve the ductility and toughness of the wire rod, tempering is performed by reheating the quenched wire rod to a lower temperature and then allowing it to cool slowly. The tempering process partially transforms the martensite into a more ductile structure known as tempered martensite. The magnetic properties of the wire rod after quenching and tempering can vary depending on the composition and cooling rate during quenching, as well as the temperature and duration of the tempering process. In conclusion, different heat treatment processes can significantly affect the magnetic properties of steel wire rod. Annealing reduces the magnetic permeability, while quenching and tempering modify the microstructure and magnetic behavior of the rod. The choice of specific heat treatment process depends on the desired magnetic properties and the intended application of the steel wire rod.

- Q:How is steel wire rod classified based on its diameter?

- Steel wire rod is classified based on its diameter into different size ranges, commonly referred to as gauges or wire sizes. These sizes can vary depending on the industry or manufacturing standards being followed.

- Q:What are the different international specifications for steel wire rod?

- Steel wire rod must meet specific requirements and characteristics outlined in various international specifications. Commonly used specifications include ASTM A510, EN 10016-2, JIS G 3505, GB/T 699, and ISO 16120-4. These standards cover carbon steel wire rods, non-alloy steel rods, low carbon steel wire rods, and general requirements for steel wire rod. Additionally, industry-specific standards and customer requirements may exist for specific applications. Consulting the relevant specifications is crucial to ensure compliance and meet application needs.

- Q:How is the steel wire rod market affected by political and economic instability?

- The steel wire rod market can be greatly influenced by political and economic instability. To begin with, changes in government, political unrest, or conflicts can disrupt the overall business environment. This uncertainty and policy changes can impact the demand and supply dynamics in the steel wire rod market. Additionally, economic instability, such as recessions, inflation, or currency fluctuations, can directly affect the steel wire rod market. During economic downturns, construction and infrastructure projects may be postponed or canceled, resulting in a decrease in demand for steel wire rods. Similarly, fluctuating exchange rates can impact the competitiveness of steel wire rod producers in the global market, potentially affecting export volumes and prices. Furthermore, political and economic instability can lead to a lack of investor confidence, which may result in reduced investment in new steel wire rod production facilities or the modernization of existing ones. This limitation can hinder the industry's ability to expand capacity or improve operational efficiency, ultimately affecting market growth and competitiveness. Moreover, political and economic instability can disrupt global supply chains, affecting the availability of raw materials and transportation logistics. Steel wire rod manufacturers heavily rely on raw materials like iron ore and coal, as well as efficient transportation networks to deliver products to customers. Any disruptions in these areas can result in increased costs and logistical challenges, which can negatively impact the market. In conclusion, political and economic stability are crucial for the steel wire rod market to thrive. A stable political environment ensures consistent policies and regulations, creating a favorable business climate. Simultaneously, economic stability provides a predictable market environment, encouraging investment and maintaining steady demand for steel wire rods.

- Q:What are the common standards for steel wire rod?

- Steel wire rod standards differ depending on the industry and specific use. However, the steel wire rod manufacturing industry generally adheres to several well-known standards. One widely accepted standard is the ASTM standard, specifically ASTM A510/A510M. This standard provides general requirements for carbon and alloy steel wire rods and coarse round wire. It covers aspects such as chemical composition, mechanical properties, dimensions, and tolerances. Another common standard is the ISO standard, specifically ISO 16120-2. This standard outlines the general requirements for non-alloy steel wire rod intended for conversion into wire. It includes details on chemical composition, mechanical properties, and dimensions. Additionally, industry-specific standards exist for steel wire rod. For instance, the automotive industry follows its own set of standards to ensure the quality and performance of steel wire rods used in automotive applications. In summary, common standards for steel wire rod include ASTM A510/A510M, ISO 16120-2, and industry-specific standards. These standards guarantee that steel wire rods meet the necessary requirements for their intended uses and promote consistency and quality during the manufacturing process.

- Q:How is steel wire rod used in the manufacturing of wire rope cables?

- Steel wire rod is used as the raw material in the manufacturing of wire rope cables. It is first drawn through a series of dies to reduce its diameter and increase its strength. The resulting wire is then twisted or braided together to form strands, which are further twisted together to create the final wire rope cable. The high tensile strength and durability of steel wire rod make it suitable for various applications, including lifting heavy loads, marine and construction industries, and suspension bridges.

- Q:What are the main challenges faced by the steel wire rod industry?

- The main challenges faced by the steel wire rod industry include fluctuating raw material prices, intense competition from alternative materials, stringent environmental regulations, and the need for continuous innovation to meet changing customer demands. Additionally, the industry is also grappling with overcapacity issues and the impact of global economic fluctuations on demand for steel wire rods.

- Q:What are the different packaging options for steel wire rod?

- The different packaging options for steel wire rod include coils, spools, bundles, and crates.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Wire Rods Hot Rolled Low Carbon Prime Quality Best Selling

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords