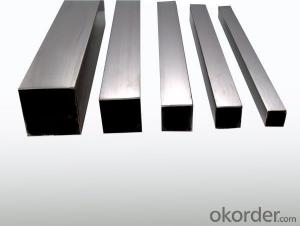

Stainless steel tube ; square tube

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | JIS,AISI,ASTM,GB | Place of Origin: | China (Mainland) | Model Number: | 304 316L 310S |

| Type: | Welded | Steel Grade: | 200 series,300 series,900 series | Application: | light industry,heavy industry,daily necessities and the decoration ind |

| Certification: | SGS | Thickness: | 0.3-100mm | Outer Diameter: | 6-1000mm |

| Item: | stainless steel square tube/pipe | Cetification: | SGS | Welding Line type: | welded |

| Quality: | High quality tube stainless steel | Package: | In plastic wrapper/wooden case/according to your requirements | Delivery: | In 15 days |

| Stock: | Available |

Packaging & Delivery

| Packaging Detail: | In plastic wrapper/wooden case/according to your requirements |

| Delivery Detail: | In 15 days |

Specifications

stainless steel square tube/pipe

T :o.3-100mm

OD:6-1000mm

Finish: bright

Quality: Top quality tube stainless steel

stainless steel square tube/pipe

Thickness:1-100mm

Outer Diameter:10-1000mm

Welding line type: ERW

Item | High quality stainless steel tube price |

Standard | ASTM A240,GB/T3280-2007,JIS4304-2005,ASTM A167,EN10088-2-2005,etc |

Material | 310S,310,309,309S,316,316L,316Ti,317,317L,321,321H,347,347H,304,304L 302,301,201,202,403,405,409,409L,410,410S,420,430,631,904L,Duplex,etc |

Thickness | 1-100mm |

Outer Diameter | Customized |

Welding line type | welded or seamless |

Package | Standard export package, suit for all kinds of transportation, or as required. |

Price term | Ex-Work, FOB, CNF, CFR, CIF, FCA, DDP, DDU, etc |

Payment term | T/T,L/C,DP,Western union |

MOQ | 500Kg |

Application | Stainless steel tube applies to construction field, ships building industry, Stainless steel tube can be made according to the customers’ requirements. |

Contact | If you have any question, please feel free to contact us. We believe customers first! |

- Q:Are stainless steel pipes suitable for oil refinery applications?

- Yes, stainless steel pipes are suitable for oil refinery applications. Stainless steel is highly resistant to corrosion, making it an ideal choice for transporting and processing oil and other petroleum products. The corrosion-resistant properties of stainless steel prevent the pipes from deteriorating due to exposure to corrosive materials and chemicals commonly found in oil refineries. Additionally, stainless steel pipes can withstand high temperatures and pressure, ensuring the safety and efficiency of oil refinery operations. Moreover, stainless steel is known for its durability and longevity, reducing the need for frequent maintenance and replacement. Overall, the use of stainless steel pipes in oil refinery applications provides a reliable and cost-effective solution.

- Q:Can stainless steel pipes be used for heat exchangers?

- Yes, stainless steel pipes can be used for heat exchangers. Stainless steel is a popular choice for heat exchangers due to its excellent corrosion resistance, high temperature resistance, and durability. It can withstand high pressure and temperature variations, making it suitable for various heat exchange applications. Stainless steel pipes also have good thermal conductivity, allowing for efficient heat transfer. Additionally, stainless steel is easy to clean and maintain, making it a reliable and long-lasting option for heat exchangers in various industries such as chemical, pharmaceutical, food processing, and HVAC.

- Q:Can stainless steel pipes be used for construction?

- Yes, stainless steel pipes can be used for construction. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for various construction applications. It is commonly used in plumbing systems, water supply lines, and underground piping where corrosion resistance is crucial. Stainless steel pipes are also used in constructing bridges, buildings, and infrastructure projects due to their strength and ability to withstand extreme weather conditions. Additionally, stainless steel's aesthetic appeal and low maintenance make it a preferred choice for architectural designs. Overall, stainless steel pipes are a reliable and long-lasting option for construction purposes.

- Q:Can stainless steel pipes be welded?

- Indeed, it is possible to weld stainless steel pipes. Due to its remarkable resistance to corrosion and strength, stainless steel is widely favored in various industries. Among the numerous techniques employed to connect stainless steel pipes, welding is a prevalent approach. Nonetheless, it is crucial to employ suitable welding techniques and equipment to guarantee a successful weld. Each grade of stainless steel has distinct welding prerequisites, necessitating the use of a filler material that corresponds to the specific grade being welded. Furthermore, it is imperative to adequately clean and prepare the surfaces that are to be welded to ensure a robust and long-lasting joint.

- Q:What's the difference between stainless steel pipe and stainless steel composite pipe?

- Stainless steel is also divided into several kinds of 200201300301304,The market is generally 301 material, 304 of the best results, followed by 301.

- Q:Can stainless steel pipes be chrome plated?

- Yes, stainless steel pipes can be chrome plated.

- Q:What's the difference between stainless steel 304 and stainless steel 202?

- Different chemical composition. 304 of the nickel is much higher than 202.

- Q:How do you cut stainless steel pipes?

- Stainless steel pipes can be cut using a variety of methods such as using a hacksaw, a reciprocating saw with a metal-cutting blade, or a pipe cutter specifically designed for stainless steel. It is important to choose the appropriate tool and blade for the job, ensuring a clean and precise cut without damaging the pipe's integrity.

- Q:Are stainless steel pipes magnetic?

- Yes, stainless steel pipes can be magnetic, depending on the specific grade of stainless steel. Stainless steel is an alloy made primarily of iron, with varying amounts of chromium, nickel, and other elements. The presence of these elements affects the magnetic properties of the stainless steel. Generally, stainless steel grades that contain a higher amount of chromium and nickel, such as the austenitic grades (e.g., 304, 316), are non-magnetic. On the other hand, stainless steel grades that have a higher amount of ferrite, such as the martensitic and ferritic grades, can be magnetic. Therefore, it is important to consider the specific grade of stainless steel when determining its magnetic behavior.

- Q:What is the difference between a pipe and a tube in stainless steel applications?

- In stainless steel applications, the main difference between a pipe and a tube lies in their structural composition and intended use. A pipe is typically designated by its inner diameter (ID) and wall thickness, and is primarily designed to transport fluids or gases. It is usually round in shape and is often used in industries such as oil and gas, chemical processing, and plumbing. Pipes are manufactured using a variety of methods, including seamless or welded processes. On the other hand, a tube is characterized by its outer diameter (OD) and wall thickness, and is commonly used for structural or mechanical purposes. Tubes can have various shapes, such as round, rectangular, or square, and are often utilized in industries such as construction, automotive, and aerospace. Tubes can also be produced through seamless or welded methods. In terms of manufacturing, pipes generally undergo stricter tolerances and quality control measures due to their transportation function, while tubes may have less stringent requirements as they are primarily used for structural applications. Additionally, pipes are commonly measured and sold by their nominal sizes, while tubes are typically specified by their actual dimensions. Both pipes and tubes can be made from stainless steel, which offers excellent corrosion resistance and durability. Stainless steel is a versatile material that is suitable for a wide range of applications, including those requiring high temperatures or exposure to harsh environments. Overall, the key distinction between a pipe and a tube in stainless steel applications is their intended purpose and structural characteristics. While pipes are designed for fluid or gas transportation, tubes are utilized for structural or mechanical applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless steel tube ; square tube

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords