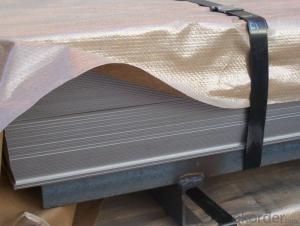

Stainless Steel sheet 201 with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/310S/309S/316L/316Ti/316/321,410/420/430/444/443/409L, and 904L.

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

1. What's the quality?

very fine

2. How long get reply?

within 24 hours

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q:Can stainless steel sheets be used for elevator interiors?

- Yes, stainless steel sheets can be used for elevator interiors. Stainless steel is a popular choice for elevator interiors due to its durability, sleek appearance, and resistance to corrosion and wear. It provides a clean and modern look, making it a suitable material for elevators in commercial buildings, hotels, and other high-traffic areas.

- Q:Can stainless steel sheets be used in outdoor environments?

- Stainless steel sheets are indeed applicable for outdoor settings. Given their exceptional resistance to corrosion, stainless steel proves to be an ideal material for outdoor uses. It can endure tough weather conditions like rain, sunlight, and temperature changes without any degradation. Moreover, stainless steel is resistant to rust, staining, and oxidation, which further amplifies its appropriateness for outdoor utilization. Consequently, stainless steel sheets have garnered widespread popularity in a range of outdoor applications such as construction, architecture, signage, and outdoor furniture.

- Q:What is the strain hardening exponent of stainless steel sheets?

- The ability of stainless steel sheets to increase their strength and hardness as they undergo plastic deformation or strain is referred to as the strain hardening exponent. This exponent measures how the stress-strain curve of the material changes as deformation increases. Typically, stainless steel sheets have a strain hardening exponent ranging from 0.2 to 0.4. This value signifies that the material experiences a moderate increase in strength and hardness when subjected to plastic deformation. A higher strain hardening exponent indicates a greater resistance to deformation and better ability to maintain its shape under external forces. The strain hardening exponent plays a crucial role in engineering applications as it impacts the material's formability, ductility, and resistance to deformation. Materials with higher strain hardening exponents are preferred in industrial processes like sheet metal forming or cold working as they offer enhanced work-hardening properties. However, excessively high strain hardening exponents can lead to issues such as cracking or material failure. It is important to acknowledge that the strain hardening exponent can vary depending on the specific grade and composition of the stainless steel alloy. Different stainless steel alloys may exhibit distinct strain hardening behaviors, necessitating consideration of the material's properties and specifications when determining the strain hardening exponent for a particular stainless steel sheet.

- Q:What is the width range available for stainless steel sheets?

- The width range available for stainless steel sheets can vary depending on the supplier, but it typically ranges from 36 inches to 72 inches.

- Q:Can stainless steel sheets be used for kitchen countertops?

- Absolutely, kitchen countertops can indeed be made from stainless steel sheets. The reason stainless steel is such a widely favored option for kitchen countertops is because of its exceptional durability, heat resistance, and hygienic qualities. It possesses a remarkable ability to ward off stains, corrosion, and rust, rendering it an ideal material for high-traffic areas, such as the kitchen. Moreover, stainless steel countertops are effortlessly cleaned and maintained, making them an extremely practical choice for bustling kitchens. Furthermore, the inclusion of stainless steel lends a polished and cutting-edge appearance to the kitchen, rendering it an exceedingly popular choice for both contemporary and industrial-style kitchens.

- Q:Can stainless steel sheets be used for swimming pool construction?

- Yes, stainless steel sheets can be used for swimming pool construction. Stainless steel is a durable and corrosion-resistant material, making it suitable for withstanding the harsh conditions of a swimming pool environment. It is commonly used for constructing pool walls, floors, and other structural components.

- Q:What is the electrical resistance of stainless steel sheets?

- The electrical resistance of stainless steel sheets can vary depending on several factors, such as the grade of stainless steel, its thickness, and the specific properties of the alloy used. Generally, stainless steel exhibits a relatively high electrical resistance when compared to other metals. This is primarily due to its composition, which includes a significant amount of chromium and other alloying elements that impede the flow of electric current. However, the precise value of electrical resistance can range from a few micro-ohms per square meter to several ohms per square meter, depending on the specific grade and thickness of the stainless steel sheet. Consequently, it is essential to refer to the manufacturer's specifications or conduct specific electrical resistance tests to obtain accurate values for a particular stainless steel sheet.

- Q:Are stainless steel sheets suitable for water treatment plants?

- Water treatment plants find stainless steel sheets highly suitable due to their excellent corrosion resistance. In such facilities, materials are constantly exposed to water and various chemicals, making this resistance crucial. Stainless steel sheets resist rust and corrosion caused by water, chlorine, chloramines, and other commonly used disinfectants in water treatment processes. Moreover, stainless steel can withstand high temperatures, making it ideal for use in water treatment plants that apply heat during specific treatment processes. Additionally, stainless steel is hygienic and easy to clean, ensuring the water remains free from contaminants or impurities. Overall, stainless steel sheets are a reliable and long-lasting choice for water treatment plants because of their corrosion resistance, durability, and hygienic properties.

- Q:Are stainless steel sheets non-magnetic?

- No, stainless steel sheets are not inherently non-magnetic. While certain types of stainless steel can be non-magnetic, such as the austenitic variety (grades like 304 and 316), many other types of stainless steel can still exhibit magnetic properties. This is particularly true for ferritic and martensitic stainless steels. The magnetism in stainless steel is determined by its composition and crystal structure. So, if you are specifically looking for non-magnetic stainless steel sheets, you should opt for the austenitic grades.

- Q:How do you prevent galling when using stainless steel sheets?

- To prevent galling when utilizing stainless steel sheets, there are several precautions that can be taken: 1. Lubrication: Apply an appropriate lubricant or anti-seize compound to the contact surfaces in order to decrease friction. This will establish a barrier between the stainless steel sheets, preventing sticking and galling. 2. Ensure proper surface finish: Verify that the stainless steel sheets possess a smooth surface finish. Rough or uneven surfaces heighten the likelihood of galling. Consider implementing sheets with a polished or finely ground finish to minimize the chance of galling. 3. Regulate contact pressure: Refrain from applying excessive pressure when working with stainless steel sheets. Excessive pressure generates heat and intensifies friction, leading to galling. Adjust the pressure to a level that allows for smooth movement without excessive friction. 4. Decrease sliding or rubbing: Diminish the amount of sliding or rubbing between stainless steel sheets. If feasible, employ rolling or lifting techniques instead of dragging or sliding the sheets against each other. This will minimize the risk of galling by reducing the contact area and friction. 5. Utilize compatible materials: When utilizing stainless steel sheets in conjunction with other materials, ensure compatibility. Certain materials, such as aluminum or specific coatings, can promote galling when in contact with stainless steel. Opt for materials that are less prone to galling or utilize protective coatings to prevent direct contact. 6. Avoid excessive heat: Excessive heat heightens the likelihood of galling in stainless steel sheets. Guarantee that the temperature is controlled and does not reach levels that could significantly heat up the sheets. This can be achieved through proper cooling methods or by implementing heat-resistant materials, if necessary. By adhering to these preventative measures, the risk of galling when utilizing stainless steel sheets can be significantly reduced. This will result in smooth operation and prolong the lifespan of the sheets.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel sheet 201 with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords