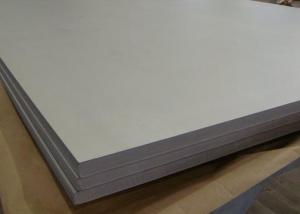

Stainless Steel Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 3500MT Per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q:Are stainless steel strips resistant to sulfuric acid?

- Generally, stainless steel strips exhibit resistance to sulfuric acid. This material is renowned for its corrosion-resistant nature and can withstand various chemicals, such as sulfuric acid, due to its high resistance. Nevertheless, the level of resistance may differ depending on the grade and composition of the stainless steel. When exposed to highly concentrated and hot sulfuric acid solutions, certain types of stainless steel may encounter limited corrosion. To ensure the appropriateness of stainless steel strips for a particular sulfuric acid application, it is advisable to seek guidance from a materials specialist or consult specific corrosion resistance charts.

- Q:Are stainless steel strips suitable for welding electrodes?

- Yes, stainless steel strips are suitable for welding electrodes. Stainless steel is a commonly used material in welding due to its high strength, corrosion resistance, and ability to withstand high temperatures. Stainless steel strips can be easily shaped into electrode forms and are compatible with various welding processes such as shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), and gas metal arc welding (GMAW). Additionally, stainless steel electrodes are known for their durability, long lifespan, and excellent arc stability, making them an ideal choice for welding applications in industries such as construction, automotive, and manufacturing.

- Q:Can stainless steel strips be cold rolled?

- Indeed, cold rolling is feasible for stainless steel strips. During this procedure, the stainless steel strip undergoes passage through a series of rollers at ambient temperature, resulting in a reduction in thickness and an enhancement of its surface finish. Cold rolling finds frequent application in the manufacturing of stainless steel strips due to its capability to bolster their strength, hardness, and dimensional precision. Furthermore, this versatile process enables the formation of stainless steel strips in varied shapes and sizes, thereby contributing to its significance in the stainless steel industry.

- Q:Can stainless steel strips be coated or painted?

- Yes, stainless steel strips can be coated or painted. Coating or painting stainless steel strips can provide a protective layer to prevent corrosion, enhance the appearance, or achieve a specific color or finish. There are various methods for coating or painting stainless steel, including powder coating, electroplating, and liquid paint. However, it is important to note that the surface of stainless steel must be properly prepared and cleaned before applying any coating or paint to ensure adhesion and long-term durability.

- Q:Can stainless steel strips be bent or folded without cracking?

- Yes, stainless steel strips can be bent or folded without cracking, as they possess high ductility and strength.

- Q:How do stainless steel strips resist intergranular corrosion?

- Stainless steel strips resist intergranular corrosion due to their unique composition and microstructure. The main factor that prevents intergranular corrosion in stainless steel is the presence of chromium in the alloy. Chromium forms a protective oxide layer on the surface of stainless steel, known as a passive film, which acts as a barrier against corrosive elements. In stainless steel, the passive film forms spontaneously when the alloy is exposed to oxygen in the atmosphere. This film is very thin but highly stable and adherent, providing excellent resistance to corrosion. It prevents the diffusion of corrosive agents, such as oxygen and chloride ions, to the underlying metal. Additionally, stainless steel strips contain other alloying elements, such as nickel and molybdenum, which also contribute to the resistance against intergranular corrosion. These elements enhance the stability of the passive film and improve the overall corrosion resistance of stainless steel. Intergranular corrosion is specifically a concern along the grain boundaries of stainless steel, where chromium depletion can occur during certain manufacturing processes or exposure to high temperatures. To mitigate this risk, stainless steel strips are often heat treated or annealed to restore the chromium content and ensure a homogeneous microstructure throughout the material. This treatment helps to maintain the integrity of the passive film and prevents intergranular corrosion. Overall, the combination of chromium content, the formation of a stable passive film, and appropriate heat treatment make stainless steel strips highly resistant to intergranular corrosion, ensuring their durability and longevity in various applications.

- Q:What are the recommended storage and transportation conditions for 111 stainless steel strips?

- The recommended storage conditions for 111 stainless steel strips include keeping them in a dry and clean environment, away from exposure to moisture, humidity, and corrosive substances. It is advisable to store them in a covered area with stable temperatures and low humidity levels. For transportation, it is crucial to protect the strips from physical damage and prevent contact with moisture or corrosive materials. Using appropriate packaging materials and ensuring secure handling during transit is highly recommended.

- Q:Can stainless steel strips be used in solar energy applications?

- Yes, stainless steel strips can be used in solar energy applications. Stainless steel is a durable and corrosion-resistant material, making it a suitable choice for various components in solar energy systems. These strips can be used in the construction of solar panels, mounting structures, frames, brackets, and other supporting elements. Stainless steel's resistance to corrosion makes it ideal for outdoor applications, as it can withstand exposure to harsh weather conditions and UV radiation without deteriorating. This ensures the longevity and reliability of solar energy systems, allowing them to function efficiently for an extended period. Furthermore, stainless steel's strength and flexibility make it appropriate for use in solar energy applications. It can be easily formed and fabricated into different shapes and sizes, allowing for customization and adaptation to various solar panel designs and mounting requirements. Stainless steel strips also contribute to the overall sustainability of solar energy systems. Their high recyclability makes them an environmentally friendly choice, aligning with the principles of renewable energy generation. Additionally, stainless steel's low maintenance requirements reduce the need for frequent replacements or repairs, further enhancing the cost-effectiveness of solar energy systems. In conclusion, stainless steel strips can indeed be used in solar energy applications due to their corrosion resistance, durability, strength, flexibility, and sustainability.

- Q:Are 111 stainless steel strips suitable for heat recovery systems?

- 111 stainless steel strips are not typically suitable for heat recovery systems. Heat recovery systems require materials that can withstand high temperatures and have good heat transfer properties. While stainless steel is known for its corrosion resistance, it may not have the necessary thermal conductivity or tolerance for high temperatures that are crucial for heat recovery systems. It is advisable to consult with a professional engineer or specialist in heat recovery systems to determine the most suitable materials for your specific application.

- Q:Can stainless steel strips be plated or coated with other metals?

- Yes, stainless steel strips can be plated or coated with other metals through various processes such as electroplating or physical vapor deposition (PVD). This allows for enhancing the appearance, improving corrosion resistance, or adding specific properties to the stainless steel strips.

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei,China |

| Year Established | 1989 |

| Annual Output Value | Above US$160 Thousand |

| Main Markets | Europe, East Asia and Southeast Asia |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 70% |

| No.of Employees in Trade Department | 30 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 14,500 square meters |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Stainless Steel Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 3500MT Per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords