Stainless Steel Plate Sheet in Bulk Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

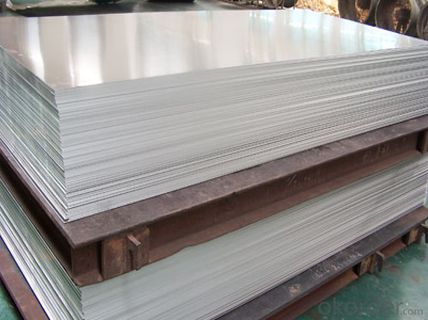

Stainless Steel Plate Sheet in Bulk Sale

Product Description

Description | steel sheet,hot rolled steel sheet,cold rolled stainless steel sheet, steel sheet,sheet,steel plate |

Material | 201,202,304,304L,309S,310S,316,316L,316Ti,317L,321,347H,409,409L,410,410S,420,430,etc. |

Thickness | From 0.3mm to 100mm |

Width | 1000mm,1219mm,1250mm,1500mm,1800mm,2200mm or be cut as your requirement |

Length | 2000mm,2438mm,2500mm,6000mm,6096mm or be cut as your requirement |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | By bulk vessel OR By container OR as customers' requirement |

Delivery time | 2-3 weeks after reciept the L/C OR T/T |

Quality | No.1 |

Productivity | 1000 tons/mouth |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

FAQ

Q: Why should you choose us:

A: 1. More than 10 years experience in this industry

2. 100,000 tons exporting per month

3. Professional foreign trade tea

4. OEM&ODM capacity

5. High quality assured & competitive price

6. Try our best to meet your needs & save your budget

7. Very popular in Southeast Asia, Africa, Mid-East and South America etc.

8. VIP membership system, first time customers and long-term cooperation customers can get extra discount on some products.

Advantages

Provide one-step purchase service to save your time, money and energy

Competive price, superior quality,and excellent logistics arrangement

Complete production line to provide full set products

Experienced facotry specialize in Building material

Professional Service team

Picture

- Q:Is stainless steel wire suitable for wire bonding?

- Certain applications can utilize stainless steel wire for wire bonding. Stainless steel wire possesses several properties that make it an advantageous option for wire bonding. Firstly, it exhibits exceptional resistance to corrosion, a crucial aspect in ensuring the long-term dependability of the wire bond. Secondly, stainless steel wire boasts commendable mechanical strength, enabling it to endure the pressures and tensions involved in the wire bonding procedure. Moreover, stainless steel wire demonstrates commendable electrical conductivity, which is essential for effective electrical connections during wire bonding. Nevertheless, it is crucial to acknowledge that stainless steel wire might not be suitable for all wire bonding applications, as other factors such as wire diameter, surface finish, and the specific bonding process employed may necessitate consideration as well.

- Q:Is stainless steel wire easy to bend?

- No, stainless steel wire is not easy to bend.

- Q:Is stainless steel wire suitable for conveyor belts?

- Yes, stainless steel wire is suitable for conveyor belts. It is highly durable, resistant to corrosion, and can withstand high temperatures, making it an ideal material for conveyor belt applications.

- Q:Can stainless steel wire be used in architectural applications?

- Architectural applications can indeed utilize stainless steel wire. This material, known for its versatility and durability, is commonly integrated into architectural designs. Its resistance to corrosion, strength, and attractive appearance make it an ideal option for various architectural applications. To enhance structural integrity, stainless steel wire can be employed in architectural projects as tension cables, wire mesh, and reinforcement. Moreover, it has decorative functions, such as being used for balustrades, handrails, and façade elements. In addition to these benefits, stainless steel wire can be easily shaped, welded, and manipulated, allowing for the creation of intricate and distinctive architectural designs. In summary, due to its practicality, longevity, and aesthetic adaptability, stainless steel wire remains a popular choice for architectural applications.

- Q:What are the common uses of stainless steel wire in the telecommunications industry?

- Stainless steel wire is commonly used in the telecommunications industry for various purposes, such as supporting and securing communication cables, providing strength and durability to antennas and towers, as well as grounding and bonding applications. Its corrosion resistance, high tensile strength, and electrical conductivity make it an ideal choice for ensuring reliable and long-lasting telecommunications infrastructure.

- Q:Is stainless steel wire suitable for springs in corrosive environments?

- Stainless steel wire is indeed suitable for springs used in corrosive environments. The reason behind its suitability lies in the outstanding corrosion resistance properties of stainless steel. This remarkable property is a result of the chromium content in the metal, which creates a protective layer on its surface, preventing both rusting and corrosion. Consequently, stainless steel wire becomes an ideal choice for springs in environments where exposure to moisture, chemicals, or other corrosive substances is probable. The resilience of stainless steel springs is evident in their ability to endure the corrosive impact of saltwater, acids, and various harsh chemicals without any signs of deterioration or loss in functionality. Moreover, stainless steel springs offer impressive strength and durability, enabling them to withstand the demanding conditions of corrosive environments for extended periods of time.

- Q:Can stainless steel wire be used for hanging artwork or decorations?

- Yes, stainless steel wire can be used for hanging artwork or decorations. Stainless steel wire is known for its strength and durability, making it a suitable choice for hanging heavier items. It is resistant to corrosion, making it ideal for indoor and outdoor use. Additionally, stainless steel wire is flexible and easy to work with, allowing for various hanging methods and configurations. Overall, using stainless steel wire ensures a secure and long-lasting installation for your artwork or decorations.

- Q:Stainless steel plate, how much silk is what?

- But in the stainless steel industry said decimillimeter, such as stainless steel plate with the thickness of 1mm, the tolerance of 0.91 plus or minus 1 wire, a tolerance of plus or minus 0.01mm 0.91mm. That is to say here is actually in mathematics centimillimeter decimillimeter.1 wire =0.01 mm

- Q:What are the different types of stainless steel wire springs used in the medical industry?

- In the medical industry, stainless steel wire springs play a crucial role in various applications. These springs are designed to provide reliable and consistent performance in medical devices and equipment. There are several different types of stainless steel wire springs commonly used in the medical industry, each with its own unique properties and applications. 1. Compression Springs: Compression springs are the most widely used type of stainless steel wire springs in the medical industry. These springs are designed to compress and provide resistance when a force is applied to them. They are commonly used in applications such as surgical instruments, medical implants, and drug delivery systems. 2. Extension Springs: Extension springs are another common type of stainless steel wire springs used in the medical industry. These springs are designed to extend and provide resistance when pulled apart. They are often used in medical devices such as stretchers, braces, and orthopedic devices. 3. Torsion Springs: Torsion springs are used to exert a rotational force or torque. They are often used in medical devices such as surgical tools, catheters, and endoscopes. Torsion springs ensure precise and controlled movement in these devices. 4. Wire Forms: Wire forms are another type of stainless steel wire springs used in the medical industry. These springs are typically custom-designed and fabricated to meet specific requirements. Wire forms are used in a wide range of medical applications, including surgical instruments, dental tools, and diagnostic devices. It is important to note that stainless steel is the preferred material for these springs in the medical industry due to its excellent corrosion resistance, biocompatibility, and sterilization capabilities. Additionally, stainless steel wire springs can withstand the harsh conditions of medical environments, including exposure to chemicals, heat, and moisture, ensuring long-lasting and reliable performance.

- Q:Can stainless steel wire be used for aerospace applications?

- Yes, stainless steel wire can be used for aerospace applications. Stainless steel has excellent corrosion resistance, high strength, and good heat resistance, making it suitable for various components and structures in aerospace engineering, such as aircraft frames, engine parts, and wiring systems.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Plate Sheet in Bulk Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords