STAINLESS STEEL PIPE CHEAP and GOOD QUALITY from CHINA

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

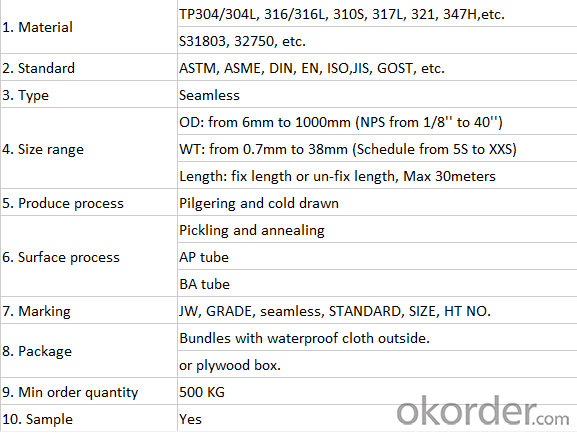

1,the breif description of the cheap and good quality stainless steel pipe

2,our advantage and specifications

1. Our company has been dedicated to producing stainless steel seamless pipe since 2003, owning complete producing technology and abundant managing experience.

2. The raw material such as mother tube, round bar we use is from Chinese biggest and well-known steel mill: Walsin Steel and Yongxing Steel.

3. We have advanced NDT equipments for the tests such as Eddy Current test, Ultrasonic test, Hydraulic test and so on.

4. We have ISO 9001 and PED certificate, and the Third Party Inspection Certificates such as TUV, BV, Lloyd’s, SGS, etc, also can be provided according to customers’ requirements,

5. Wooden case package which is strong and suitable for sea transportation is our main method to pack the pipes. And the economical packing method such as packed in bundles is also welcomed by some customers.

6. The tolerance control we use is D4/T4 (+/-0.1mm) on both inside and outside Diameter and Wall Thickness, which is much higher than international standard ASTM, DIN.

7. The surface condition is one of our main advantages: in order to meet different requirements for surface condition, we have annealing and pickling surface, bright annealing surface, OD polished surface, OD & ID polished surface etc.

8. In order to keep the inside surface of pipe clean and make it free from deburring, our company develops the unique and special technology --- Sponge Washing with high pressure.

9. We have complete after-sale service to deal with the problems in time.

3,Stainless steel maintenance:

(1) Regular cleaning and maintenance

(2) Pay attention to prevent the occurrence of the phenomenon of surface scratches

(3) Use soap, weak detergent or warm water to remove surface dust, dirt

(4) In addition to the surface of the binder with alcohol or an organic solvent (ether, benzene)

(5) Use neutral detergent or ammonia solution in addition to surface oil

(6) With 10% nitric acid or abrasive detergent in addition to the surface of the embroider caused by the dirt.

4,FAQ

1. Q: What are your advantageous Products?

A: We specialized in 400 series cold rolled stainless steel coils and plates. Our main products are 430, 410S and 409L.

We also supply stainless steel strips and strips in coil as requested.

2. Q: Can you make DDQ ( Deep Drawing Quality)?

A: Yes, we can. Our material can be used for stainless steel pots, stainless steel sinks, stainless steel bowls etc. U can tell us your usage, and we will adjust the mechanical propertise to meet your requirement.

- Q:Can stainless steel pipes be used for gas transportation?

- Yes, stainless steel pipes can be used for gas transportation. Stainless steel is known for its high resistance to corrosion, making it suitable for transporting various gases, including natural gas and liquefied petroleum gas (LPG). Additionally, stainless steel pipes are strong and durable, ensuring the safe and efficient transportation of gas.

- Q:What is the difference between 321 and 316 stainless steel pipes?

- The main difference between 321 and 316 stainless steel pipes lies in their chemical composition and intended applications. 321 stainless steel pipes contain titanium, which stabilizes the material against chromium carbide formation. This makes it highly resistant to intergranular corrosion, even at elevated temperatures. As a result, 321 stainless steel pipes are commonly used in applications where high temperatures are involved, such as in the aerospace and power generation industries. On the other hand, 316 stainless steel pipes do not contain titanium but have molybdenum in their composition. This addition enhances the material's corrosion resistance, particularly in environments with chloride ions, making it suitable for applications in marine and coastal environments. Additionally, 316 stainless steel pipes are often used in the food and beverage industry due to their excellent resistance to acids and chemicals. In summary, while both 321 and 316 stainless steel pipes offer excellent corrosion resistance, the presence of titanium in 321 stainless steel pipes provides enhanced resistance to intergranular corrosion at high temperatures, whereas the addition of molybdenum in 316 stainless steel pipes improves their resistance to chloride-based corrosion in marine and coastal environments.

- Q:Can stainless steel pipes be used for irrigation sprinkler systems?

- Indeed, irrigation sprinkler systems can utilize stainless steel pipes. Renowned for their durability, strength, and resistance to corrosion, stainless steel pipes prove to be an exceptional preference for irrigation setups. They possess the ability to endure high water pressure and are less prone to rust or decay over time in comparison to alternative materials, such as PVC or galvanized steel. Furthermore, stainless steel pipes guarantee hygienic conditions and do not taint the water supply, rendering them a secure choice for irrigation systems. Nevertheless, it remains crucial to take into account factors like cost and compatibility with existing infrastructure prior to opting for stainless steel pipes in irrigation sprinkler systems.

- Q:How do you calculate the expansion of stainless steel pipes?

- To calculate the expansion of stainless steel pipes, you need to consider the coefficient of thermal expansion (CTE) of the material. The CTE is a measure of how much a material expands or contracts when subjected to temperature changes. First, determine the initial length of the stainless steel pipe. This is the length of the pipe at the starting temperature. Next, determine the final temperature at which the pipe will be operating. This is the temperature at which you want to calculate the expansion. Find the CTE value for the particular grade of stainless steel used in the pipe. The CTE is typically given in units of per degree Celsius (or per degree Fahrenheit). Multiply the initial length of the pipe by the CTE value and then multiply it by the change in temperature. This will give you the expansion or contraction of the pipe in the given temperature range. For example, let's say you have a stainless steel pipe with an initial length of 10 meters, a CTE of 17 x 10^-6 per degree Celsius, and you want to calculate the expansion at a final temperature of 100 degrees Celsius. The change in temperature would be 100 degrees Celsius (final temperature) minus the initial temperature. Expansion = Initial Length * CTE * Change in Temperature Expansion = 10 meters * 17 x 10^-6 per degree Celsius * 100 degrees Celsius Expansion = 0.0017 meters or 1.7 millimeters Therefore, the stainless steel pipe would expand by 1.7 millimeters when subjected to a temperature increase of 100 degrees Celsius. It's important to note that this calculation assumes a uniform expansion along the entire length of the pipe. In reality, thermal expansion may vary due to factors such as pipe diameter, wall thickness, and other structural considerations. Therefore, it's recommended to consult with industry standards or engineering references for more accurate calculations in specific applications.

- Q:Can stainless steel pipes be insulated with polyethylene naphthalate?

- No, stainless steel pipes cannot be insulated with polyethylene naphthalate.

- Q:What are the maintenance requirements for stainless steel pipes?

- The maintenance requirements for stainless steel pipes include regular cleaning to remove dirt and debris, inspection for signs of corrosion or leaks, and occasional lubrication of any moving parts. Additionally, it is important to avoid contact with corrosive substances and to promptly address any maintenance issues to prevent further damage.

- Q:What is the difference between double wall and single wall stainless steel pipes?

- When comparing double wall and single wall stainless steel pipes, their construction and applications are the key distinguishing factors. Single wall stainless steel pipes are composed of a single layer of stainless steel. They find common use in various industrial settings, including plumbing, heating, ventilation, and air conditioning systems. These pipes are renowned for their durability, resistance to corrosion, and high tensile strength. They are suitable for transporting fluids and gases at moderate temperatures and pressures. On the contrary, double wall stainless steel pipes consist of an inner and outer layer of stainless steel, with insulation sandwiched in between. The insulation layer provides thermal insulation, preventing the transfer of heat and maintaining the desired temperature of the fluid or gas within the pipe. Double wall stainless steel pipes are typically employed in applications where temperature control is crucial, such as high-temperature industrial processes or the transportation of hot or cold fluids. Due to the presence of insulation, double wall stainless steel pipes exhibit superior energy efficiency compared to single wall pipes. They reduce heat loss or gain, thereby minimizing energy consumption and optimizing the efficiency of heating or cooling systems. Furthermore, the insulation layer also aids in reducing condensation, which can prevent damage to surrounding equipment or structures. In conclusion, the main distinction between double wall and single wall stainless steel pipes lies in the inclusion of an insulation layer in double wall pipes. This insulation layer grants them thermal insulation, making them ideal for applications that necessitate temperature control and energy efficiency. Conversely, single wall pipes are commonly utilized in various industrial settings where insulation or stringent temperature control is not required.

- Q:What is the difference between SCH and XS stainless steel pipes?

- SCH and XS are two different schedules or pipe thicknesses used in stainless steel pipes. SCH stands for schedule and XS stands for extra strong. The main difference between SCH and XS stainless steel pipes lies in their wall thickness. SCH pipes have a standard thickness range, while XS pipes have a thicker wall compared to SCH pipes. SCH pipes are commonly used for general-purpose applications where high pressure is not a major concern. They are available in various schedules, such as SCH 5, SCH 10, SCH 40, and so on. The higher the schedule number, the thicker the wall of the pipe. SCH pipes are suitable for low to medium pressure applications. On the other hand, XS pipes are designed to handle higher pressure and are often used in more demanding applications. XS pipes have a thicker wall compared to SCH pipes, providing additional strength and durability. They are commonly used in industries such as oil and gas, chemical processing, and power plants, where high pressure and corrosive environments are present. In summary, the main difference between SCH and XS stainless steel pipes is the thickness of their walls. SCH pipes have a standard thickness range, while XS pipes have a thicker wall specifically designed for high-pressure applications.

- Q:Can stainless steel pipes be used in chemical processing plants?

- Yes, stainless steel pipes can be used in chemical processing plants. Stainless steel is a popular choice for piping systems in these plants due to its excellent corrosion resistance properties. Chemical processing plants often deal with corrosive materials and high temperatures, and stainless steel pipes are capable of withstanding these harsh conditions. Stainless steel is resistant to many chemicals, including acids, bases, and chlorides, which are commonly found in chemical processing plants. Additionally, stainless steel has a smooth interior surface, which reduces the risk of corrosion and allows for easy cleaning and maintenance. Overall, stainless steel pipes are a reliable and durable option for transporting chemicals in chemical processing plants.

- Q:What is the difference between seamless and seamless redrawn stainless steel pipes?

- Seamless stainless steel pipes and seamless redrawn stainless steel pipes are both types of pipes made from stainless steel, but they differ in their manufacturing processes and properties. Seamless stainless steel pipes are produced by piercing a solid billet of stainless steel and then rolling it into a seamless tube using various methods, such as hot rolling, cold rolling, or extrusion. This process does not involve any welding or joining of separate pieces, resulting in a continuous, seamless pipe. Seamless pipes are known for their superior strength, durability, and resistance to corrosion. On the other hand, seamless redrawn stainless steel pipes are manufactured by taking a seamless pipe and subjecting it to a secondary process called cold drawing or cold rolling. In this process, the pipe is pulled through a die or a series of dies to reduce its diameter and improve its surface finish. This cold drawing process enhances the dimensional accuracy, surface finish, and mechanical properties of the pipe. The main difference between seamless and seamless redrawn stainless steel pipes lies in their manufacturing processes and resulting properties. Seamless pipes are generally considered to have higher strength and corrosion resistance than redrawn pipes due to their uninterrupted grain structure and absence of welds. They are commonly used in applications that require high pressure, temperature, or corrosive resistance, such as oil and gas pipelines, chemical processing plants, and power generation facilities. Seamless redrawn stainless steel pipes, although slightly inferior in strength and corrosion resistance compared to seamless pipes, offer improved dimensional accuracy, surface finish, and tight tolerances. They are often used in industries like automotive, aerospace, and pharmaceuticals, where precise dimensions and excellent surface quality are critical. In summary, while both seamless and seamless redrawn stainless steel pipes are made from stainless steel and offer various advantages, the choice between them depends on the specific requirements of the application, such as the level of strength, corrosion resistance, dimensional accuracy, and surface finish needed.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

STAINLESS STEEL PIPE CHEAP and GOOD QUALITY from CHINA

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords