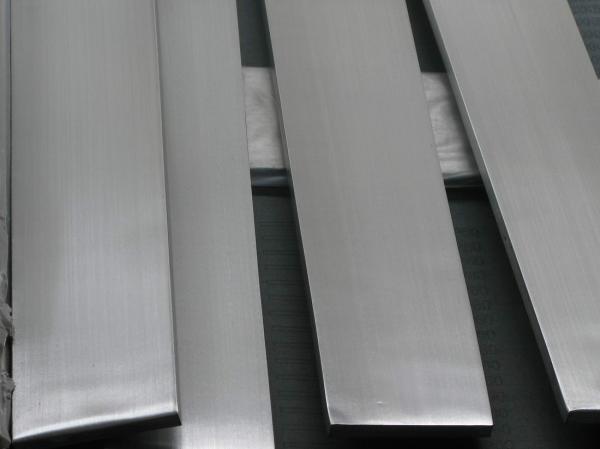

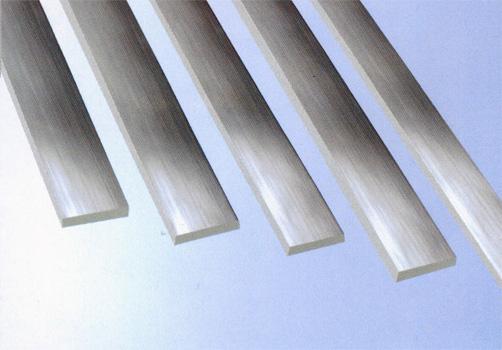

Stainless Steel Flats

- Loading Port:

- Shanghai Port or Others

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Flats

1. Standard: AISI, GB, JIS, ASTM, DIN, EN

2. Grade: 1).200Series: 201,202.

2).300Series: 301,302,303,304,304L,316,316L,321.

3).400Series: 410,410S,416,420,430,430F.

3. Size:3x25mm- 80x250mm

4. Length: 2m-6m

5. Craft: HRAP, or cold drawn

6. Stainless Steel Flat Bar Surface: Pickling or polished

7. MOQ: 1000kg

8. Delivery: within 20 days

9. Package: Waterproof with tape

10. Application: These products are widely supplied to areas of machine-made industry, chemical industry, shipping industry,architecture, food industry, household products etc.

|

Name |

Stainless Steel Flat Bar | ||||||||

|

Material |

201.202.301.304.304L,304N,304LN, 309S,310S,316,316L, 316Ti,316N,316LN,317,317L,347, 347H,etc. | ||||||||

|

Standard |

JIS/AISI/ ASTM,/GB,/DIN,/EN/SUS.etc. | ||||||||

Shape |

Stainless steel Round/flat/square/angle/hexagonal bar | ||||||||

Price term |

FOB/CIF/CNF or as required | ||||||||

|

Length |

6m,5.8m,4m as required | ||||||||

|

Application |

kitchen and sanitary wares , and Structural use high strength components,furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc | ||||||||

|

Payment terms |

L/C,T/T,Western Union,or as required. | ||||||||

|

MOQ |

As required | ||||||||

|

Packing |

Export standard package | ||||||||

|

Certificate |

ISO/SGS | ||||||||

|

Contact |

If you are interested in our products,please feel free to contact me. Cherryliu@okorder.com |

- Q:Are stainless steel pipes suitable for brewing systems?

- Yes, stainless steel pipes are highly suitable for brewing systems. Stainless steel is the preferred material for brewing equipment due to its excellent corrosion resistance, hygienic properties, and durability. Stainless steel pipes do not react with the acidic components present in brewing, ensuring that there are no unwanted flavors or contaminants introduced into the beer. Additionally, stainless steel pipes are easy to clean and maintain, making them ideal for the brewing process. Overall, stainless steel pipes provide a reliable and long-lasting solution for brewing systems, ensuring the production of high-quality and uncontaminated beer.

- Q:How is stainless steel pipe manufactured?

- Stainless steel pipe is manufactured through a process called pipe making. This process involves several steps that ensure the production of high-quality and durable stainless steel pipes. The first step in manufacturing stainless steel pipes is the selection of the raw materials. Stainless steel, which is a combination of iron, chromium, and other elements, is chosen for its corrosion-resistant properties. The specific grade and composition of stainless steel are carefully selected based on the intended application of the pipe. Once the raw materials are selected, they are melted in a furnace. This melting process is known as the electric arc furnace process. The stainless steel is heated to high temperatures, typically around 1700 degrees Celsius, to form a molten metal. After the molten metal is formed, it is transferred to a continuous casting machine. This machine helps in creating a solid cylindrical shape known as a billet. The billet is then transferred to a rolling mill where it is shaped into a seamless pipe. The rolling mill consists of multiple stands that gradually reduce the thickness and diameter of the billet. The billet is passed through these stands multiple times, with each pass reducing its size further. This continuous rolling process ensures the uniformity and consistency of the stainless steel pipe. Once the desired size is achieved, the pipe is cut to the required length. This is done using saws or other cutting tools. The ends of the pipe are then prepared for welding or other joining methods. In some cases, stainless steel pipes may undergo additional processes such as heat treatment or surface finishing. Heat treatment helps in improving the mechanical properties of the pipe, while surface finishing can provide enhanced aesthetics or corrosion resistance. Finally, the stainless steel pipes are inspected for quality and compliance with industry standards. This may involve various testing methods such as visual inspection, dimension and wall thickness measurement, non-destructive testing, and chemical analysis. Overall, the manufacturing of stainless steel pipes involves a combination of melting, casting, rolling, cutting, and inspection processes. These processes ensure the production of high-quality stainless steel pipes that are suitable for a wide range of applications including plumbing, construction, and industrial uses.

- Q:How do you prevent rusting in stainless steel pipes?

- To prevent rusting in stainless steel pipes, there are several measures that can be taken: 1. Regular Cleaning: Regularly clean the stainless steel pipes using mild soap or detergent and warm water. This helps to remove any dirt, debris, or contaminants that can cause corrosion. 2. Avoid Abrasive Cleaners: Avoid using abrasive cleaners, steel wool, or harsh chemicals as they can scratch the surface of the stainless steel and compromise its protective layer. 3. Protect from Chlorides: Stainless steel pipes should be protected from exposure to chlorides, such as those found in saltwater or certain cleaning agents. If the pipes are installed in areas where these substances are present, it is important to apply protective coatings or use specialized stainless steel grades that are resistant to corrosion caused by chlorides. 4. Proper Ventilation: Ensure that the stainless steel pipes are properly ventilated to prevent the buildup of moisture, which can accelerate the rusting process. Adequate airflow helps to keep the pipes dry and reduces the risk of corrosion. 5. Regular Inspections: Regularly inspect the stainless steel pipes for signs of rust or corrosion. If any damage or rust spots are detected, they should be addressed promptly to prevent further deterioration. 6. Passivation: Passivation is a chemical treatment process that helps to enhance the corrosion resistance of stainless steel. It involves removing any contaminants from the surface and promoting the formation of a protective oxide layer. Passivation should be done by professionals who are experienced in handling stainless steel. 7. Cathodic Protection: In some cases, cathodic protection can be used to prevent rusting in stainless steel pipes. This involves using sacrificial anodes or impressed current systems to create an electrochemical reaction that protects the stainless steel from corrosion. By following these preventive measures, you can significantly reduce the risk of rusting in stainless steel pipes and ensure their longevity and durability.

- Q:Are stainless steel pipes suitable for brewery applications?

- Stainless steel pipes prove to be highly suitable for brewery applications with their exceptional corrosion resistance, durability, and hygienic properties, making them the preferred material in the brewing industry. These pipes can endure the challenging conditions of a brewery environment, including exposure to hot liquids and cleaning chemicals, without succumbing to corrosion or contaminating the beer. Furthermore, the smooth surface of stainless steel pipes aids in preventing the accumulation of bacteria and other impurities, ensuring a superior level of cleanliness and quality throughout the brewing process. Moreover, stainless steel is effortlessly cleaned and maintained, adding to its practicality for breweries. In conclusion, stainless steel pipes are a dependable and efficient choice for brewery applications.

- Q:Can stainless steel pipes be used for firefighting systems?

- Firefighting systems can utilize stainless steel pipes due to their durability and resistance to corrosion. The material's ability to withstand heat, pressure, and chemicals makes it suitable for transporting water, foam, and other fire suppression agents. In addition to its high strength and ability to endure extreme conditions, stainless steel pipes are also recognized for their smooth inner surface, which reduces friction loss and maximizes water flow. This quality is crucial for the effectiveness of firefighting operations. Overall, stainless steel pipes offer a dependable and long-lasting solution for firefighting systems, ensuring safety and efficiency in critical situations.

- Q:What is the difference between Schedule 10 and Schedule 40 stainless steel pipes?

- The main difference between Schedule 10 and Schedule 40 stainless steel pipes lies in their wall thickness. Schedule 10 pipes have a thinner wall thickness, making them lighter and more economical, suitable for low-pressure applications. On the other hand, Schedule 40 pipes have a thicker wall, providing higher strength and durability, making them suitable for high-pressure applications.

- Q:What are the common sizes of stainless steel pipes?

- The sizes of stainless steel pipes commonly differ based on their intended use and industry standards. However, a range of sizes are commonly found, including 1/8 inch, 1/4 inch, 3/8 inch, 1/2 inch, 3/4 inch, 1 inch, 1 1/4 inch, 1 1/2 inch, 2 inch, 2 1/2 inch, 3 inch, 4 inch, 5 inch, 6 inch, 8 inch, 10 inch, 12 inch, 14 inch, 16 inch, 18 inch, 20 inch, 24 inch, and 36 inch. These sizes are typically determined by the outside diameter (OD) of the pipe. It is important to acknowledge that slight variations in these sizes may occur depending on the specific standards followed by the manufacturer or industry.

- Q:What is the difference between electropolished and mechanically polished stainless steel pipes?

- The main difference between electropolished and mechanically polished stainless steel pipes lies in the method used to achieve the desired surface finish. Electropolishing involves immersing the pipe in an electrolyte solution and applying an electric current, which removes a thin layer of metal and impurities, resulting in a smooth, clean, and corrosion-resistant surface. On the other hand, mechanical polishing involves abrasive materials, such as sandpaper or polishing wheels, to physically remove imperfections and create a smooth surface. Both methods can enhance the aesthetics and performance of stainless steel pipes, but electropolishing offers superior cleanliness, corrosion resistance, and a more uniform finish.

- Q:How do you prevent contamination in stainless steel pipes?

- To prevent contamination in stainless steel pipes, proper cleaning and maintenance practices should be followed. This includes regular inspection and removal of any buildup or deposits, ensuring that the pipes are properly sealed to prevent ingress of contaminants, and avoiding contact with substances that can cause corrosion or contamination. Additionally, implementing a proper filtration system and adhering to recommended hygiene protocols can further prevent contamination in stainless steel pipes.

- Q:Are stainless steel pipes suitable for underground applications?

- Yes, stainless steel pipes are suitable for underground applications. Stainless steel is known for its high resistance to corrosion, making it an excellent choice for underground installations where pipes are exposed to moisture, soil, and other corrosive elements. It can withstand harsh environments and maintain its structural integrity over time. Stainless steel pipes also have high strength and durability, ensuring they can handle the pressure and stress of being buried underground. Additionally, stainless steel is non-reactive, so it does not contaminate the water or fluid flowing through the pipes. Overall, stainless steel pipes are a reliable and long-lasting option for underground applications.

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei,China |

| Year Established | 2009 |

| Annual Output Value | Above US$1 million |

| Main Markets | Asia, Middle East,America |

| Company Certifications | CE, CCC, ISO90001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 0.3 |

| No.of Employees in Trade Department | 4 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 5,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Lower |

Send your message to us

Stainless Steel Flats

- Loading Port:

- Shanghai Port or Others

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords