Single Building Hoist New Lifting Machines

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Single Building Hoist New Lifting Machines

The hoist adopted with the normal electrical control method, is equipped with contactor, control transformer, anti-overheat protector, relay against the phase failure & disorder. All the electrical parts are equipped with Schneider and Siemens products.

The inverter, as a key controlling part, is used in the hoist adopted with VFD+PLC control method. This device is jointly developed by Japan Yaskawa and us. The hardware is supplied by Yaskawa, while the controlling software is supplied by us ensuring safe & reliable operations. PLC controller adopts OMROM products; brake unit is from YASKAWA and other electrical components are from Schneider or Siemens.

With application of VFD, it’s able to realize stepless speed regulating between zero and max speed. There are two shifting-gears set in the operating platform. One is maintenance shift, which can enable the cage run at speed of 0~5M/min for user to check the lubricating condition and connection of the machine’s parts. The other is working shift, enabling the cage with normal working speed. By adopting this control method, it’s also able to check and show the condition of power supply, operation and electrical failure. Moreover, it can avoid misoperation, giving great protection to transmission & electrical system.

Main Parts of Building Hoist

1. Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

2. Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process, and ensures automated leveling.

3. Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

4. The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

5. The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack, pinion and the brake and prolongs the spare parts'life.

6. The VF system also has the over voltage protection,low voltage protection, overcurrent, overload and anti-stalling protection functions,

7. The system applies the special software for hoists developed by our company, making the operation more safe and reliable.

Building Hoist images

CMAX Building Hoist

Anchorage System

Driving Unit

Warehouse

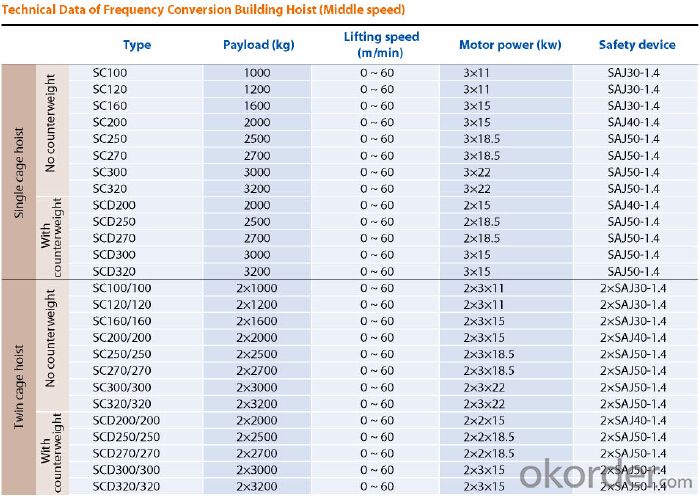

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance & exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q:Is the construction elevator a special equipment

- The construction elevator is special equipment, the installation and demolition of the special construction plan, after the installation, the special equipment can be tested and qualified for use

- Q:Do the elevator need to be installed when the main project is in construction

- The top brass usually need to install the construction elevator.

- Q:How does the construction elevator add up

- The principle is simple Now, the construction of a manned, cargo-carrying construction elevator is a gear rack. You can't understand how to say that you can't understand

- Q:Does the new approach builder need a localizer test report

- Need, not for safety device testing qualified report, inspection agency will not issue the inspection report, in the construction of elevator installation supervision and inspection report, there is a specifically for, for safety device must have testing qualified report, to be certified.

- Q:Construction elevator positioning should consider which problems

- The construction elevator is short for construction. It is an important equipment in high-rise building construction, and construction site accident hazards easily, because it can cause many major accidents, injuries in the inspection should be listed as a key to check the content. Based on past accidents and on-site inspections, we often find topics that we think should be examined in a critical area

- Q:What's going on with the decline in construction lift

- Check whether the brake contactor and normal, contactor adhesion conditions will decline, brake pads have the problem not only rise to fall, fall in the same slide. If the contactor is ok, you can see that there is a groove on the brake pad, and it is only replaced if the brake is not damaged, such as cracking. If it's a frequency conversion elevator, if you're down, see if the converter has any fault code, if you have a consulting manufacturer. The assumption is that the anchuan frequency converter, which may be a real SE failure, means that the timing error is not normal for controlling the contact of the receiver.

- Q:Safe use of construction elevator

- In the case of passenger and carriage, the loading shall be uniformly distributed, and the overload shall be strictly prohibited. When the elevator runs to the top and lowest levels, it is strictly forbidden to stop at the collision or lower limit. 7. The driver for leaving hanging basket and while going off work, should be hanging basket fell to the ground, to cut off the total power supply, and the door is locked point, prevent other undocumented workers start the hoisting cage without authorization. Wind up above 6, should stop using the elevator and bring the cage down to the ground. There must be good protection on both sides of the transportation channel. Floor door should be in a normally closed state, its height should conform to the requirements of the specification, anyone shall not open or head out of the door, when the floor door open, the driver shall not start the elevator. Ensure that the communication device is in good condition and the driver should be able to start the lift after confirming the signal. The driver should immediately execute any emergency stop signal on the floor of the operation. The elevator should be installed on a separate ground protection and lightning protection device. It is strictly forbidden to do maintenance work under the condition of the elevator. If maintenance is required, the power supply must be cut off and the sign of "check in, shut off" will be hung in a prominent place.

- Q:A lift motor is 7.5 KW, and the frequency converter sends current 4.2 A, which has A heating resistance in the converter, and how the charge is calculated when the lift is full. Or consider the power of the converter and the power of the thermal resistance.

- Try using the security software. There is a cracked version

- Q:What about the energy efficiency of the escalator

- The frequency conversion construction elevator is now basically the mainstream product, the effect is good, the failure rate is low and so on the advantage.

- Q:The difference between the derrick and the construction elevator?

- They're the same. HAULOTTE answer for you

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Single Building Hoist New Lifting Machines

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords