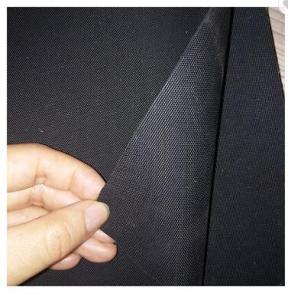

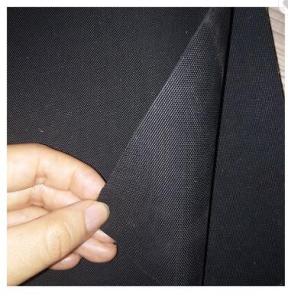

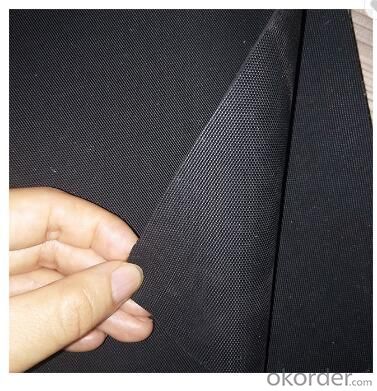

Roofing Waterproof Membrane/EPDM Rubber Sheet

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Membrane Specifications:

EPDM rubber waterproof membrane is made from ternary ethylene-propylene rubber, which is designed for waterproofing projects applications, which has high flexibility and bendable property for all kinds of buildings.

Type | EPDM Rubber Waterproof Membrane | ||

Type | Vulcanized and Weldable | ||

Thickness | 1.2mm | 1.5mm | 2.0mm |

Weight(kg/m2) | 1.54-1.58 | 1.79-1.83 | 2.25-2.29 |

Size | 1.2m (width) * 20m (length)/roll. Weldable type could be 4m wide. | ||

Packing | 24㎡/roll, with plastic bag. (Weldable: 80㎡/roll) | ||

Usage | Roof, basement, pond, Lake, steel structure roofing, underground, tunnel, etc | ||

EPDM Waterproof Membrane Property:

•Excellent anti-ageing,prolonged longevity;long service life.

•Good strength and tensity/Suitable for a wide range of temperatures

•Great high-temperature,low-temperature resistance

•Single layer applied is applicable and cold applied

EPDM Waterproof Membrane Application:

Applicable to all kinds of roofing, basement, tunnel light building waterproofing engineering;

roofing and underground engineering, storage tanks, municipal, bridges, subways, tunnels, dams, etc.

- Q:What are the specific applications of geosynthetic clay liners in mining projects?

- Geosynthetic clay liners (GCLs) find specific applications in mining projects primarily for the containment of liquids or gases. They are used as a barrier system in mining operations to prevent the migration of contaminants into the surrounding environment, such as groundwater or nearby water bodies. GCLs are commonly used in mining projects for lining tailings storage facilities, heap leach pads, and evaporation ponds, providing an effective and impermeable barrier to prevent the leakage of potentially harmful substances. Additionally, GCLs can also be used in the construction of surface impoundments, landfills, and waste containment cells within mining operations to ensure proper containment and environmental protection.

- Q:Are earthwork products suitable for use in railway construction?

- Yes, earthwork products are commonly used in railway construction as they provide stability, support, and cost-effectiveness for various railway infrastructure elements such as embankments, cuttings, and platforms.

- Q:What are the advantages of using geogrids in earthwork projects?

- Geogrids offer several advantages in earthwork projects. Firstly, they enhance soil stability by providing reinforcement and increasing the load-bearing capacity of the soil. This helps in constructing structures on weak or poor-quality soils. Secondly, geogrids distribute the applied load more evenly, reducing the potential for differential settlement and minimizing the risk of structural failure. Additionally, they improve the overall performance and longevity of the project by reducing the need for excessive excavation or the use of costly reinforcement materials. Lastly, geogrids are easy to install, cost-effective, and environmentally friendly, making them a preferred choice for engineers and contractors in various earthwork applications.

- Q:What are the different load capacities available for earthwork products?

- The load capacities available for earthwork products vary depending on the specific product and its intended use. Some common load capacities for earthwork products include 1 ton, 2 tons, 5 tons, 10 tons, and even higher capacities for heavy-duty applications. It is important to consult the manufacturer or supplier for the specific load capacity of the earthwork product you are interested in, as it may vary based on factors such as size, material, and design.

- Q:Can earthwork products be used for constructing stormwater detention ponds?

- Yes, earthwork products can be used for constructing stormwater detention ponds. These products, such as soil, clay, and gravel, can be used to shape the pond's basin, create berms or embankments, and provide stability to the structure. The earthwork materials play a crucial role in managing and containing stormwater runoff, preventing flooding, and improving water quality.

- Q:Are there any specific earthwork products available for athletic field construction?

- Yes, there are specific earthwork products available for athletic field construction. These include materials such as topsoil, sand, gravel, and drainage systems, which are used to create a suitable playing surface and ensure proper water management on the field. Additionally, specialized earthwork products like geotextiles may be used for erosion control and stabilization purposes.

- Q:The Relationship between Material Development and Civil Development

- Civil engineering, the main construction of various structures, to create a new structure, in addition to the structure of its own innovation, the main material and process innovation.

- Q:How do geocomposites help in erosion control in earthwork applications?

- Geocomposites help in erosion control in earthwork applications by providing an effective barrier against soil erosion. They are made up of multiple layers, typically consisting of a geotextile and a geomembrane, which work together to prevent the movement of soil particles and the loss of vegetation. The geotextile layer acts as a filter, allowing water to pass through while retaining soil particles, and the geomembrane layer acts as a barrier, preventing water from infiltrating the soil and causing erosion. This combination of layers helps to stabilize slopes, control runoff, and protect the underlying soil, ultimately reducing erosion and improving the overall durability of earthwork structures.

- Q:What is the purpose of using geonets in wastewater treatment systems?

- The purpose of using geonets in wastewater treatment systems is to enhance the filtration and drainage capabilities of the system. Geonets act as a support layer that helps distribute and evenly flow the wastewater through the treatment process, improving the efficiency of filtration and reducing the risk of clogging. Additionally, geonets also provide stability and reinforcement to the system, preventing soil erosion and maintaining the structural integrity of the treatment system.

- Q:What are the different colors and textures available in earthwork products?

- The colors and textures available in earthwork products can vary depending on the specific material. For example, in soil products, colors can range from various shades of brown to gray, while the textures can range from fine and sandy to coarse and gravelly. Additionally, in rock and stone products, colors can range from vibrant reds and yellows to more subdued grays and blacks, with textures varying from smooth and polished to rough and jagged.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Roofing Waterproof Membrane/EPDM Rubber Sheet

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords