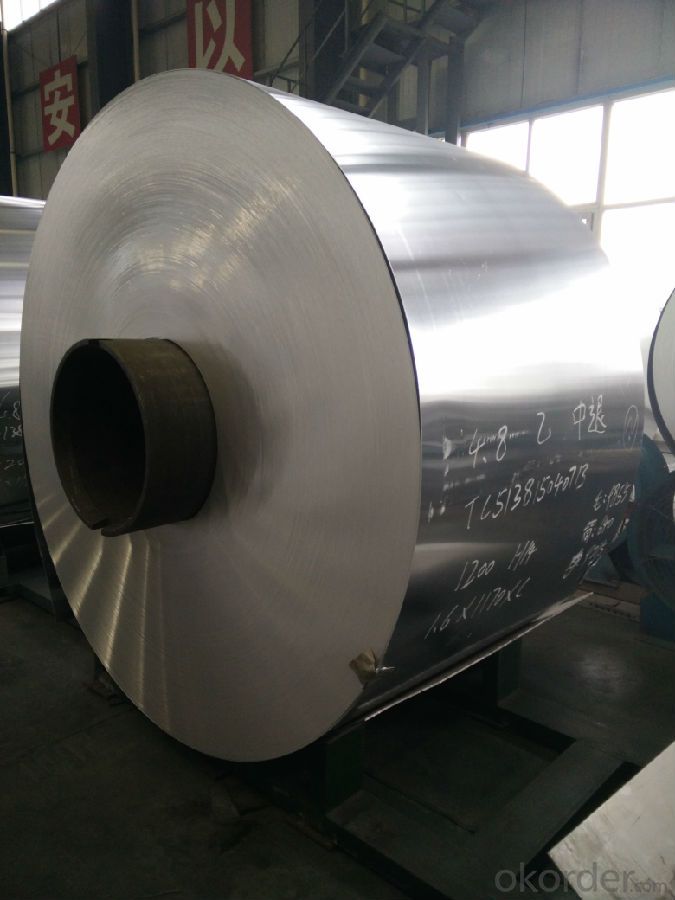

Roll of Aluminum 3003 H14 /1100 H14

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Roll of Aluminum 3003 H14 /1100 H14

Roll of Aluminum 3003 H14 /1100 H14 is designed for many field such as electronics, instruments, lighting decoration, packing industry, and house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel, aluminum composite pipe etc.. Roll of Aluminum 3003 H14 /1100 H14 is hard and everlasting under the blazing sun. You can choose the alloys as your habitation and we will do our best to meet your requests.

2.Main Features of the Roll of Aluminum 3003 H14 /1100 H14:

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

3. Roll of Aluminum 3003 H14 /1100 H14

Alloy: 1050, 1060, 1070, 1100, 3003, 3004, 3005, 3105, 5052, 5083, 5754, 8011, 8006

Temper: H14, H16, H18, H22, H24, H26, H32, O/F

Thickness: 0.2mm-100mm

Width: 30mm-1700mm

4. Production of Roll of Aluminum 3003 H14 /1100 H14

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q:What are the potential applications of coil-coated aluminum coils?

- Coil-coated aluminum coils possess exceptional properties and versatility, thus presenting a wide range of potential applications. Some notable uses of coil-coated aluminum coils include: 1. Construction and Architecture: The construction industry extensively employs coil-coated aluminum coils for roofing, wall cladding, facades, and decorative elements. These coils can be easily shaped and customized to meet specific design requirements, while their coil coating ensures durability, weather resistance, and color retention. 2. Transportation: Coil-coated aluminum coils find widespread usage in the transportation industry, particularly in the manufacturing of automobiles, buses, trains, and aircraft. The lightweight nature of aluminum makes it an ideal choice for enhancing fuel efficiency and energy conservation. Moreover, the coil coating enhances corrosion resistance, aesthetics, and overall durability of the aluminum coils. 3. Appliances and Electronics: Manufacturing appliances and electronics, including refrigerators, air conditioners, ovens, and televisions, commonly involves the use of coil-coated aluminum coils. The coil coating provides a protective layer that prevents corrosion and extends the lifespan of these products. Additionally, the aesthetic appeal and variety of colors offered by coil-coated aluminum coils contribute to the overall design and aesthetics of appliances and electronics. 4. Signage and Displays: The versatility and visual appeal of coil-coated aluminum coils make them a popular choice for signage and displays. The coil coating enhances the durability, weather resistance, and color vibrancy of the aluminum, making it suitable for both indoor and outdoor applications. Whether it be large billboards, shop signs, or exhibition displays, coil-coated aluminum coils offer a cost-effective and visually appealing solution. 5. Packaging: Coil-coated aluminum coils are extensively used in the packaging industry for various purposes, such as cans, containers, and lids. The coil coating provides a protective layer that prevents the aluminum from reacting with the contents, ensuring product integrity and safety. Additionally, the lightweight nature of aluminum makes it an environmentally friendly option for reducing packaging waste. 6. Energy and Solar: The energy and solar industry is increasingly incorporating coil-coated aluminum coils. The lightweight and corrosion-resistant nature of aluminum make it an ideal material for manufacturing solar panels and energy-efficient systems. The coil coating further enhances the durability and weather resistance of the aluminum, ensuring long-term performance in different environmental conditions. In conclusion, coil-coated aluminum coils have vast and diverse potential applications, ranging from construction and transportation to appliances, signage, packaging, and the energy industry. The combination of excellent properties, including lightweight, durability, weather resistance, and aesthetic appeal, make coil-coated aluminum coils a preferred choice in numerous sectors.

- Q:How do aluminum coils perform in saltwater environments?

- Due to their innate resistance to corrosion, aluminum coils exhibit exceptional performance in saltwater environments. Unlike other metals, aluminum develops a protective oxide layer upon exposure to saltwater, effectively creating a barrier that prevents further corrosion. This durable and long-lasting oxide layer acts as a shield against the harsh effects of saltwater, guaranteeing the longevity and efficiency of aluminum coils in marine applications. Furthermore, the lightweight nature and high thermal conductivity of aluminum coils make them widely favored for use in heat exchangers and condensers within saltwater-based cooling systems. In conclusion, aluminum coils are extensively relied upon and highly efficient in saltwater environments, establishing them as the preferred choice for a range of marine applications.

- Q:The company wants to produce an aluminum coil production line, which is better for large aluminium smelting equipment?

- Dongpu heat well, they have the qualification certificate issued by the state kiln construction, as far as I know, their melting furnace Aluminum Alloy 'plan is very good, and the operation is simple and safe, feel good, can be wiped off

- Q:How are aluminum coils used in the construction industry?

- Aluminum coils are widely used in the construction industry for various purposes such as roofing, siding, and insulation. These coils are typically formed into sheets or panels which are then used to create durable and lightweight structures. Additionally, aluminum coils are often employed in the manufacturing of gutters, fascia, and soffit systems, enhancing the overall aesthetics and functionality of buildings. Due to their corrosion resistance and high strength-to-weight ratio, aluminum coils are favored for their longevity and ease of installation, making them a popular choice in the construction industry.

- Q:How much is one square aluminum gate and five hard door?

- Double layer aluminum alloy, in the middle of the 5 bars, ordinary white or beige is 215, a square, the motor, in addition, the general 600KG copper core motor has 550 sets, there are 680 sets.

- Q:helicopters rotorblades are made of honeycombed aluminum to give them strength, so isn't it a good idea for automakers to use the same technology to strengthen the frames of autos to make them lesslikely to cave in during a side impact auto accident?

- I'm not sure you are using Honeycombed aluminum in the right context. Honeycombed aluminum is generally a method of taking a solid sheet of aluminum and carving out areas so that rails of honeycombs are left on one side and the other still looks solid. However this is not done for strength, it is done for the weight savings. Like you said, helicopter rotors are milled so that the aluminum is honeycombed, but this is to shave off a few hundred pounds of metal, which means more passengers or lifting capability. Now honeycombed aluminum has about 70% of the strength of solid aluminum, given its impacted at the right angle. In this respect it could be used on cars to give comparable strength but give far better fuel economy just because your not lugging around all that weight.

- Q:hello I'm building a TIG welder and have found the output from my stick welders to be not so good for aluminum(60 Hz on one). I've heard that high frequency AC is the way to do AL but am not sure what constitutes high. I do have a nice miller gas driven welder also that is maybe triple the frequency of my line driven one but still had issues with it. does anyone know of an actual # ? I may be able to build an inverting PWM supply eventually to do this but am not sure what I would need it to do. does anyone have any data that might help? any data/tips about aluminum would be appreciated, thanks in advance. FYI I do understand why AC works so much better on AL, what with the oxides that are always present.

- NO... the TIG rods are uncoated and will not be able to create the shielding gas like coated rods would when used in an ARC welder. TIG (Tungsten Inert Gas) uses a shielding gas supplied from a tank, the aluminum rods are used as filler material and metled into the weld by the operator by using the arc from the tip as the heat source. Two different welding processes, hence the need for two different types of rods...

- Q:What is the typical hardness of aluminum coils?

- The typical hardness of aluminum coils can vary depending on various factors such as the alloy composition, tempering process, and intended application. Generally, aluminum coils are manufactured in a range of hardness levels to cater to different needs and requirements. Aluminum coils can be produced in different tempers, including soft, half-hard, and full-hard. Soft aluminum coils have low hardness and are more malleable, making them suitable for applications that require easy formability such as packaging and wrapping materials. Half-hard aluminum coils are moderately hardened and offer a balance between formability and strength, making them suitable for applications like roofing and siding. Full-hard aluminum coils have the highest hardness and provide excellent strength, making them ideal for applications that require structural integrity such as automotive parts and construction materials. To determine the specific hardness of aluminum coils, various testing methods such as Rockwell hardness, Vickers hardness, or Brinell hardness can be employed. These tests measure the resistance of the aluminum surface to indentation and provide a numerical value that indicates the material's hardness. However, it is essential to consult the manufacturer or supplier for specific hardness values as it can vary depending on the specific alloy and temper of the aluminum coil.

- Q:Can aluminum coils be recycled?

- Indeed, it is possible to recycle aluminum coils. Due to its exceptional recyclability, aluminum stands as one of the frequently recycled materials. The procedure for recycling aluminum coils encompasses melting them to eliminate impurities and subsequently molding them into fresh products or coils. By recycling aluminum coils, not only are natural resources preserved, but also energy consumption and greenhouse gas emissions are diminished relative to the production of new aluminum from primary materials.

- Q:Can aluminum coils be formed into different shapes?

- Yes, aluminum coils can be formed into different shapes. Aluminum is a highly malleable metal, which means it can easily be bent, shaped, and formed without breaking. This property makes it an ideal material for various applications where flexibility and versatility are required. Aluminum coils can be formed into different shapes using a variety of techniques, such as bending, rolling, stamping, extrusion, or even by using specialized machinery like a coil forming machine. These processes allow the aluminum coils to be transformed into a wide range of shapes, including sheets, plates, tubes, wires, or complex three-dimensional forms. The ability to form aluminum coils into different shapes makes it an excellent choice for industries such as construction, automotive, aerospace, and manufacturing, where customized parts and components are often needed.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Roll of Aluminum 3003 H14 /1100 H14

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords