Refractory High Alumina Thermal Insulating Fire Brick

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

65% Al2O3 Min High Alumina Insulating Fire Brick

High alumina insulating fire brick is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of High Alumina Insulating Fire Brick are made of selected high alumina bauxite, kaolin caly, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature.

Product Applications:

High alumina insulating fire brick are ideal for use in the below applications

Building materials for blast furnace

Building materials for hot-blast stove

Building materials for coke oven

Building materials for steel making furnace

For construction material in steel industry

For ladle

Product Advantages:

CNBM has success in its High alumina insulating fire brick due to their cost-effectiveness and excellent insulating properties. The refractoriness of magnesia chrome bricks are more than 2000°C, and the refractory under load is a above 1550°C.Good steady volume in high temperature, the performance of meeting sudden cold and sudden hot is better than magnesia bricks.

Main Product Features:

Excellent thermal stability

High refractoriness under load

Chemical stability and anti-corrision

Small high temperature creep rate

Excellent thermal shock resistance

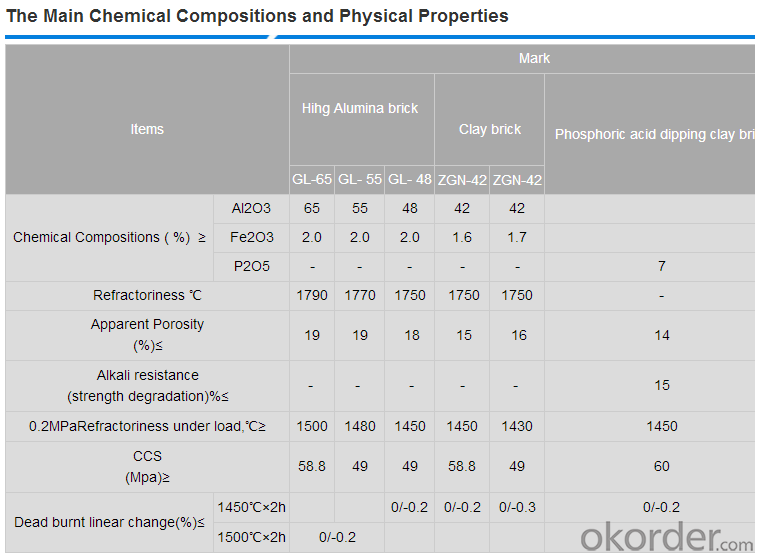

Product Specifications:

FAQ:

Q1: Are you a manufacture or trader?

A1: Factory+trade (mainly for manufacturing, also do some business of related products).

Q2: What's the MOQ of trial order?

A2: No limit,We can offer the best suggestions and solutions according to your requirements.

Q3: After an order is confirmed,when to deliver?

A3: According to your order quantity, normally, 15-25 days after deposit received.

Q4: Is your company accept customization?

A4: We have our own factories and excellent technical team, and we accept OEM service.

Product Picture

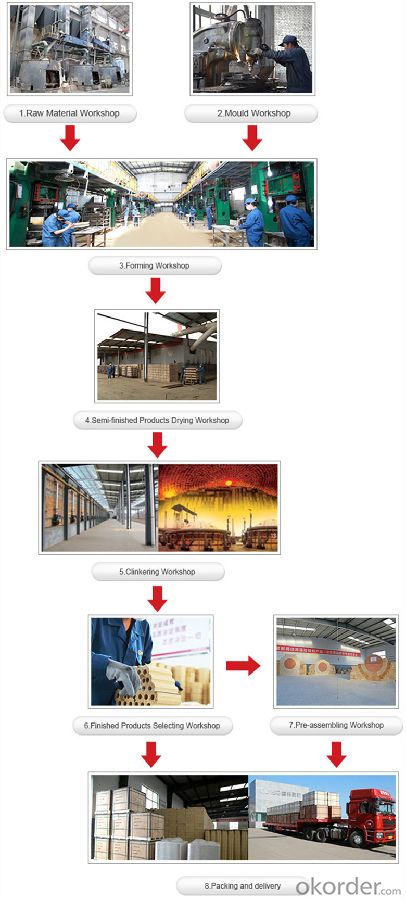

Produce Processing

- Q:Are insulating fire bricks resistant to vibration or seismic activity?

- Yes, insulating fire bricks are typically resistant to vibration or seismic activity. They are designed to withstand high temperatures and provide insulation, which also makes them relatively stable and resistant to external forces such as vibrations or seismic activity.

- Q:Are insulating fire bricks resistant to alkali attack?

- Yes, insulating fire bricks are generally resistant to alkali attack. These bricks are made from high-temperature refractory materials and are designed to withstand extreme temperatures and chemical environments. Alkalis are known to corrode and degrade certain materials, but insulating fire bricks are specifically formulated to resist this type of chemical attack. They have a low porosity and dense structure, which helps prevent the penetration of alkalis into the brick's surface. Additionally, the refractory materials used in these bricks have a high melting point and are chemically inert, making them well-suited for applications where alkali exposure is a concern. However, it is important to note that the specific resistance of insulating fire bricks to alkali attack may vary depending on the composition and manufacturing process of the brick, as well as the concentration and duration of alkali exposure. Therefore, it is always recommended to consult with the manufacturer or supplier for detailed information about the resistance of their specific insulating fire bricks to alkali attack.

- Q:Do insulating fire bricks have a high insulating capacity?

- Yes, insulating fire bricks have a high insulating capacity. These bricks are designed to have low thermal conductivity, which helps in reducing heat transfer and maintaining high temperatures in industrial applications such as furnaces and kilns. They provide excellent insulation, making them highly effective in conserving energy and reducing heat loss.

- Q:Are insulating fire bricks suitable for insulation in cryogenic applications?

- Yes, insulating fire bricks are suitable for insulation in cryogenic applications. Insulating fire bricks have excellent thermal insulation properties, low thermal conductivity, and can withstand extremely low temperatures. This makes them ideal for use in cryogenic applications where insulation is required to maintain the low temperature of the system.

- Q:Can insulating fire bricks be used in the construction of pottery extruders?

- Yes, insulating fire bricks can be used in the construction of pottery extruders. Insulating fire bricks are known for their high heat resistance and insulation properties, making them ideal for applications involving high temperatures, such as pottery kilns and extruders. These bricks can withstand the intense heat generated during the pottery extrusion process, ensuring the longevity and durability of the extruder. Additionally, their insulation properties help to maintain a consistent temperature within the extruder, which is crucial for achieving precise and consistent results in pottery production. Therefore, using insulating fire bricks in the construction of pottery extruders is a reliable and effective choice.

- Q:Do insulating fire bricks require any special curing or firing temperature profiles?

- Special curing and firing temperature profiles are indeed necessary for insulating fire bricks. These bricks are made from lightweight materials like perlite, vermiculite, or alumina silicate, all of which possess exceptional insulating properties. Their design enables them to endure high temperatures while providing superior thermal insulation. Throughout the manufacturing process, insulating fire bricks undergo a curing procedure to eliminate any moisture content. This is typically achieved by gradually raising the temperature in a controlled manner. The curing process is essential to prevent any potential cracking or damage that may occur if the bricks were subjected to high temperatures too quickly. When it comes to firing temperature profiles, careful consideration is required for insulating fire bricks. They are specifically designed for applications where temperatures can reach up to 2800°F (1538°C). Therefore, it is crucial to adhere to the recommended firing temperature profiles provided by the manufacturer. The firing temperature profile usually involves a gradual increase in temperature to allow the insulating fire bricks to reach the desired maximum temperature without experiencing any thermal shock or damage. This gradual heating process ensures that the bricks are adequately cured and capable of withstanding the extreme temperatures they will encounter during use. It is worth noting that the specific curing and firing temperature profiles may vary depending on the type and composition of the insulating fire bricks. Consequently, it is vital to consult the manufacturer's guidelines and recommendations to ensure the proper curing and firing process for the specific type of insulating fire bricks being utilized.

- Q:What is the density of insulating fire bricks?

- Insulating fire bricks usually have a density ranging from 0.6 to 1.5 grams per cubic centimeter (g/cm³), but this can vary depending on their specific composition and manufacturing process. These bricks are purposely made with lower density than regular fire bricks, enabling them to possess superior insulating qualities. The reduced density aids in minimizing heat transfer and enhancing energy efficiency in diverse applications like furnaces, kilns, and ovens.

- Q:Can insulating fire bricks be used in the construction of industrial dryers?

- Yes, insulating fire bricks can be used in the construction of industrial dryers. These bricks have excellent thermal insulation properties, which make them ideal for retaining heat within the dryer and reducing heat loss. Additionally, insulating fire bricks are resistant to high temperatures, making them suitable for the extreme heat generated in industrial dryers.

- Q:Can insulating fire bricks be used in the construction of flue gas ducts?

- Insulating fire bricks have the capability to be utilized in the construction of flue gas ducts. These bricks are specifically engineered to endure high temperatures and offer exceptional thermal insulation. This makes them an apt choice for lining flue gas ducts as they aid in reducing heat loss and enhancing energy efficiency. Moreover, insulating fire bricks exhibit resistance to chemical corrosion and can withstand the harmful impacts of flue gases. Nevertheless, it is crucial to guarantee that the insulating fire bricks employed are specifically designed for flue gas duct applications and fulfill the required safety and regulatory standards. Seeking advice from a professional engineer or a specialist in this field is advised to ensure the accurate selection and installation of insulating fire bricks in flue gas ducts.

- Q:Can insulating fire bricks be used in ceramic kilns?

- Certainly, ceramic kilns can make use of insulating fire bricks. These bricks are specifically crafted to possess a minimal thermal conductivity, enabling them to better retain heat. Consequently, they prove to be an excellent option for lining the kiln walls, facilitating the conservation and uniform distribution of heat within the kiln chamber. Furthermore, these fire bricks are lightweight and possess exceptional resilience against thermal shock, rendering them highly durable and capable of withstanding the elevated temperatures commonly achieved in ceramic kilns.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refractory High Alumina Thermal Insulating Fire Brick

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords