PVC Coated Polyester Geogrid for Civil Engineering and Road Contruction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polyester Geogrid Introduction

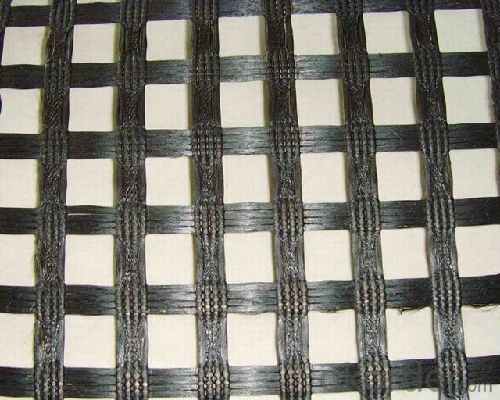

The warp knitting polyster geogrid use excel raw materials, with warp knitting oriented structrue , latitude and longitude in the fabric to the yarn between not curving condition, the intersection unifies mutually with the excel in textile fiber filament bundle, forms the reliable combining site, displays its mechanical properties fully.

Polyester Geogrid Features

Transmits high tensile forces with low elongation

High ultimate tensile strength

Excellent long-term behavior due to low creep effects

High resistance to soil micro-organisms and chemicals, UV radiation and mechanical damage

Good grid/soil interaction through optimum sizing of the geogrid mesh to suit the maximum coarse particle size of the soil

Ease of installation through low weight per unit area and flexible, adaptable structure

Very wide range of available strengths, uniaxial and biaxial structures

Polyester Geogrid Application

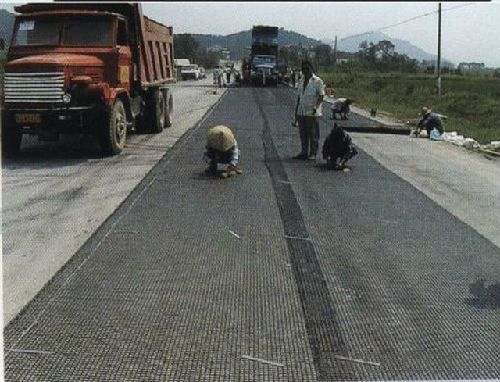

Structural layers supporting road, railway and airport construction

Site access roads and transport routes

Retaining walls and steepened slopes

Slope stabilization

Noise reduction barriers

Rehabilitation of waste ground

Earth embankments over piles

Landfill

Bridging of voids and sinkholes

Polyester Geogrid Specifications

Property | Test Method | PET | PET | PET | PET | |

40-25 | 50-35 | 60-30 | 80-30 | |||

Ultimate tensile strength(1)(kN/m) | MD | EN ISO 10139 | 25 | 35 | 30 | 30 |

CD | 40 | 50 | 60 | 8 | ||

Elongation at maximum load(%) | MD | 13 | ||||

CD | 13 | |||||

Approximate mesh size(mm) | 12.7mm×12.7mm , 25.4mm×25.4mm , 40mm×40mm | |||||

Roll Width (m) | 1m-6m | |||||

Roll Length(m) | 50m-200m | |||||

FAQ

1. What's the usage of geogrid?

It's used for reinforce the roadbeds in softe soil, railway, tunnel, slope and embankment etc. It has good performance on preventing the cracks.

2. How about your quality of geogrid?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

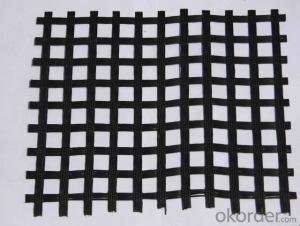

Polyester Geogrid Product Photos

- Q:Classification and application of polyethylene geogrid?

- The utility model is suitable for the construction of roads, railways, rivers, lakes, and coastal areas, such as reinforced retaining walls, dams, bridge decks, steep slopes and geocell. Its function is to improve the bearing capacity of the retaining wall or embankment, prolong the service life, reduce the occupation area, shorten the construction period, reduce the cost and reduce the maintenance cost.

- Q:What are the specifications of the road geogrid

- Reference to the national standard, but the specifications are not necessarily the same as the national standard.

- Q:Plastic grid plate making process

- Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and fiberglass polyester geogrid. The plastic geogrid is a kind of polymer material with square or rectangular shape which is formed by stretching, and it can be used as two kinds of uniaxial tension and biaxial tension. The utility model is punched on the extruded polymer plate (raw material is polypropylene or high-density polyethylene), and then directionally stretched under the heating condition. The unidirectional stretching grid is only drawn along the length direction of the plate, and the bidirectional stretching grid is made by stretching the unidirectional stretching grid in the direction perpendicular to the length.

- Q:What are the benefits of using geogrids in construction projects?

- Geogrids offer several benefits in construction projects, including increased soil stability, improved load distribution, and enhanced overall structural integrity. These materials reinforce and stabilize the soil, preventing erosion and reducing the risk of slope failure. Geogrids also help distribute loads more evenly, reducing stress on the construction materials and extending their lifespan. Additionally, geogrids can be cost-effective as they often require less excavation and backfill material, saving time and resources during construction.

- Q:Can geogrids be used in reinforcement of soil-bentonite mixtures?

- Yes, geogrids can be used in the reinforcement of soil-bentonite mixtures. Geogrids are commonly used as a geosynthetic material to enhance the stability and strength of soil and other materials. When combined with soil-bentonite mixtures, geogrids can improve the overall performance and load-bearing capacity of the mixture. The geogrids provide reinforcement and prevent the potential failure or deformation of the soil-bentonite mixture, making it a suitable option for various engineering applications.

- Q:Are geogrids effective in reducing soil settlement?

- Yes, geogrids are effective in reducing soil settlement. They provide reinforcement and stabilization to the soil, preventing excessive settlement and maintaining the integrity of the ground. By distributing the load and increasing the load-bearing capacity of the soil, geogrids help to minimize settlement and ensure long-term stability.

- Q:How to do a good job ah? How to start the sale of geotechnical materials

- Everything is difficult at the beginning, and now the competition in the field of materials industry has entered a white hot, slowly come, more run the site, running more than the site, will naturally..

- Q:How do geogrids enhance the stability of steep road embankments?

- Geogrids enhance the stability of steep road embankments by providing reinforcement to the soil. They are installed within the embankment to distribute the tensile forces and prevent soil erosion or slippage. The geogrids act as a stabilizing layer, improving the overall strength and integrity of the embankment, making it more resistant to lateral movement and increasing its load-bearing capacity.

- Q:Can geogrids be used in erosion control applications on steep slopes?

- Yes, geogrids can be used in erosion control applications on steep slopes. Geogrids are commonly used to reinforce and stabilize soil, preventing erosion from occurring. They provide strength and stability to the soil, allowing for better resistance against erosion forces, even on steep slopes.

- Q:How do geogrids help in reducing the risk of settlement of structures?

- Geogrids help in reducing the risk of settlement of structures by providing reinforcement to the soil, improving its stability and preventing excessive settlement. They distribute the load more evenly, increase the bearing capacity of the soil, and minimize the potential for differential settlement, which can cause structural damage. The geogrids effectively restrain the lateral movement of soil particles, preventing them from shifting and settling excessively, thereby ensuring the long-term stability and durability of the structures.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Coated Polyester Geogrid for Civil Engineering and Road Contruction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords