PPR Fitting Elbow with unequal diameter on sales with Food Hygiene Regulations and Non-toxic

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 9100 pc

- Supply Capability:

- 520000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Features

1. Corrosion resistance

PPR pipes and fittings can resistant to most chemical corrosion; it can withstand PH value range 1-14 high concentration of acid and alkali corrosion over a wide temperature range.

2. Installation performance

PPR pipe PPR pipe is light in weight, and the operation installation is easy, which make it available to weld again. It is very important that pipe and pipe fittings can be welded together in seconds with a simple tool. Compared to traditional connection methods it can save 40%~50% of the time.

3. Safety Indicators

The basic component of PPR is carbon and hydrogen which is simple. It keeps in line with food hygiene regulations, non-toxic. If you use PPR pipe, there will no dirt in the inner wall or “secondary water pollution” caused by rust any more.PPR pipe ,green building materials, is more suitable for transporting drinking water.

Advantages of PPR pipe

1. Maximum operating temperature can up to 95℃; it can work in a long term under the condition of 70℃ and 1.0Mpa.

2. PPR pipe density is only 1/8 of metal pipe; pressure resistance strength test is up 5Mpa, with good toughness, impact resistance.

3. Inner diameter of PPR pipe is little bigger than that of pipe fittings, which can ensure not to increase the resistance to fluid flow.

4. Inner wall of PPR pipe is smooth, no rust, no scaling, small fluid resistance

5. PPR pipe has excellent insulation properties, can significantly reduce the vibration and noise caused by the flow of liquid.

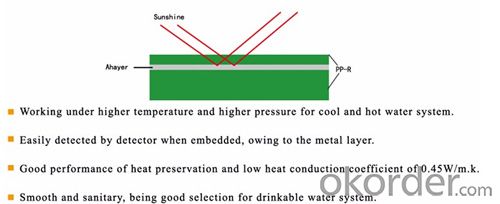

6. PPR pipe energy consumption is only 20% of steel pipe; its thermal coefficient is also only 1/200 of steel pipe, reducing heat loss greatly.

7. PPR pipe is poor electrical conductor material, which can avoid galvanic corrosion phenomena.

8. With poor thermal conductivity, PPR pipe can reduce condensation.

9. PPR pipes, fittings are recyclable.

Application

1. Hot and cold drinking water supply system of civil and industrial buildings

2. Clean, pure water piping system

3. Beverage production and transport systems

4. Industrial liquid delivery system

5. Central air conditioning system

6. Hot water circulation Heating System

7. Compressed air piping system

8. Garden and greenhouse irrigation systems

FAQ

Features of PPR Pipes

PP-R pipe as a new pipe, has the following characteristics:

1. The production of energy saving PP-R pipe is only 20% of the steel pipe, and its low thermal conductivity [0.2W / (mK)], is only 1/200 of steel pipe, used in hot water systems will be greatly reduced heat loss.

2. Corrosion-resistant, non-scaling, hygiene, wall using non-toxic PP-R pipe can be removed from the use of galvanized steel pipe caused by fouling, rust and water quality caused by the "secondary pollution." Since PP-R component simple, basic component of carbon and hydrogen, in line with food hygiene regulations, non-toxic, more suitable for transporting drinking water.

3. Heat, pressure, long life and long-term use temperature of PP-R pipe up to 95 ℃, short-term use temperature up to 120 ℃. The temperature is 70 ℃, working pressure of 1.2MPa conditions, the long-term continuous use, life expectancy up to 50 years.

4. Lightweight, high strength, fluid resistance PP-R pipe density of only 1/8 of metal pipes, pressure resistance strength test up 5MPa, and good toughness, impact resistance. The smooth wall has no rust, no scaling, fluid resistance. The main technical indicators PP-R pipe is as follows: the density of 0.9g / cm3 modulus of elasticity (20 ℃) 800MPa thermal expansion coefficient of 1.8 × 10-4 / K thermal conductivity of 0.2W / (mK) longitudinal shrinkage rate of 2% impact ≤10% hydraulic test short-term trials breakage rate 1h, ring stress 16MPa no leakage long 95 ℃, 1000h, hoop stress 3.5MPa no leakage table 1 performance comparison of several pipe material.

PP-R pipe in addition to general plastic pipe has a light weight, corrosion-resistant, non-scaling, long life and other characteristics, but also has the following main features:

1. Non-toxic, health. Molecular material PP-R only carbon and hydrogen elements, no harmful toxic elements are present, reliable health, not only for hot and cold plastic water pipe, can be used to clean drinking water systems.

2. Thermal insulation. PP-R pipe thermal conductivity coefficient of 0.21w / mk, steel is only 1/200.

3. Good heat resistance. Vicat softening point of PP-R pipe 131.5 ℃. Maximum operating temperature of up to 95 ℃, plastic water pipe can meet the water supply and drainage requirements specification hot water system.

4. Long service life. PP-R pipe in working temperature 70 ℃, working pressure (P.N) 1.OMPa conditions, the service life of up to 50 years; at room temperature (20 ℃) the service life of up to 100 years.

5. Easy PPR installation, reliable connection. PP-R has good welding properties, pipe, pipe fittings can be used hot-melt and fused connections, easy PPR installation, the joint firm, which is greater than the strength of the connection portion of the strength of the pipe itself.

6. Recyclable materials. After cleaning, after crushing PP-R waste can recycle in pipe, tube production. If recycled material amount does not exceed 10% of the total, does not affect pp-r pipes and fittings product quality.

- Q:Can plastic tubes be used for chemical analysis?

- Yes, plastic tubes can be used for chemical analysis. They are commonly used in various laboratory settings for sample collection, storage, and transportation. Plastic tubes offer advantages such as being inert, transparent, and resistant to chemical reactions, making them suitable for a wide range of analytical techniques.

- Q:Can plastic tubes be used for industrial labeling?

- Yes, plastic tubes can be used for industrial labeling. They are commonly used in various industries such as manufacturing, warehousing, and logistics to label products, shelves, containers, and equipment. Plastic tubes offer durability, flexibility, and resistance to water, chemicals, and UV rays, making them suitable for industrial environments. They can be easily customized with labels, barcodes, or QR codes to provide clear identification and tracking.

- Q:How long do plastic tubes typically last?

- The lifespan of plastic tubes can vary depending on various factors such as the type of plastic, the environment they are exposed to, and the specific application they are used for. However, in general, plastic tubes can last anywhere from a few months to several years.

- Q:How do you store plastic tubes to prevent warping?

- To prevent warping of plastic tubes, it is recommended to store them in a cool and dry environment, away from direct sunlight or heat sources. It is also advisable to store them in an upright position, using a rack or container that provides support to the tubes and prevents any bending or deformation.

- Q:Are plastic tubes suitable for use in the telecommunications industry?

- Yes, plastic tubes are suitable for use in the telecommunications industry. They are lightweight, flexible, and can easily be installed in various settings. Plastic tubes are also resistant to corrosion and offer protection to the cables and wires used in telecommunications systems.

- Q:What's the difference between the water supply U-PVC plastic pipe and the UPVC plastic pipe?

- U-PVC plastic pipe and UPVC pipe without distinction, just writing methods are not the same, it refers to the rigid PVC pipe, UPVC water supply pipe is a sanitary PVC (PVC) resin as the main raw material, adding non-toxic stabilizers, lubricants, fillers, coloring agent by plastic extruder pipes and fittings molding and injection molding machine injection molding production etc.. The regular UPVC plastic tube formula has no hygienic requirement, and some additives are harmful to human body.

- Q:My little sister is worried! Please help! He already chew on a piece of paper on accident.

- hamsters chew on everything. tell her not to worry, i used to work at a pet store and iv'e never herd of a hamster dieing from chewing on plastic. although it wouldn't be bad to put a little piece of wood in there that is clean for it to chew.

- Q:How do plastic tubes compare to fluoropolymer tubes in terms of chemical resistance?

- Fluoropolymer tubes generally have superior chemical resistance compared to plastic tubes.

- Q:What are the advantages of using plastic tubes in the medical packaging industry?

- There are several advantages of using plastic tubes in the medical packaging industry. Firstly, plastic tubes provide excellent protection against breakage, ensuring the safe transportation of medical products. Secondly, plastic tubes are lightweight, making them cost-effective for shipping and storage purposes. Additionally, plastic tubes offer superior barrier properties, protecting the contents from moisture, gases, and light. Moreover, plastic tubes are customizable, allowing for ease of labeling and branding. Lastly, plastic tubes are recyclable, making them an environmentally friendly option for the medical packaging industry.

- Q:Is home tap water iron or plastic good?

- In the past, pipes used for water supply were mainly cast iron pipes. Outside the main use sand mold cast iron pipe, indoor use is galvanized iron pipe. However, due to the use of a few years later, it is easy to produce a large number of rust, bacteria, and seriously endanger the health of the human body. The state has set out in June 1, 2000 to eliminate sand casting pipe fittings and cold galvanized iron pipes, and gradually limit the use of hot cast iron pipes, and promote the use of aluminum plastic composite pipes, new plastic pipes and so on.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PPR Fitting Elbow with unequal diameter on sales with Food Hygiene Regulations and Non-toxic

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 9100 pc

- Supply Capability:

- 520000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords