PP Biaxial Geogrid with High Tensile Strength Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specification---PP Biaxial Geogrid

Introduction:

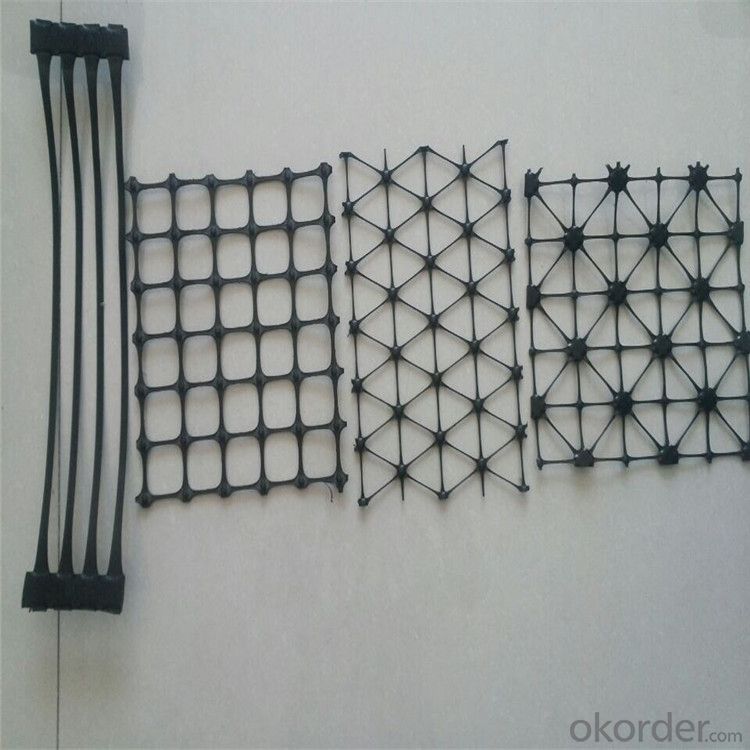

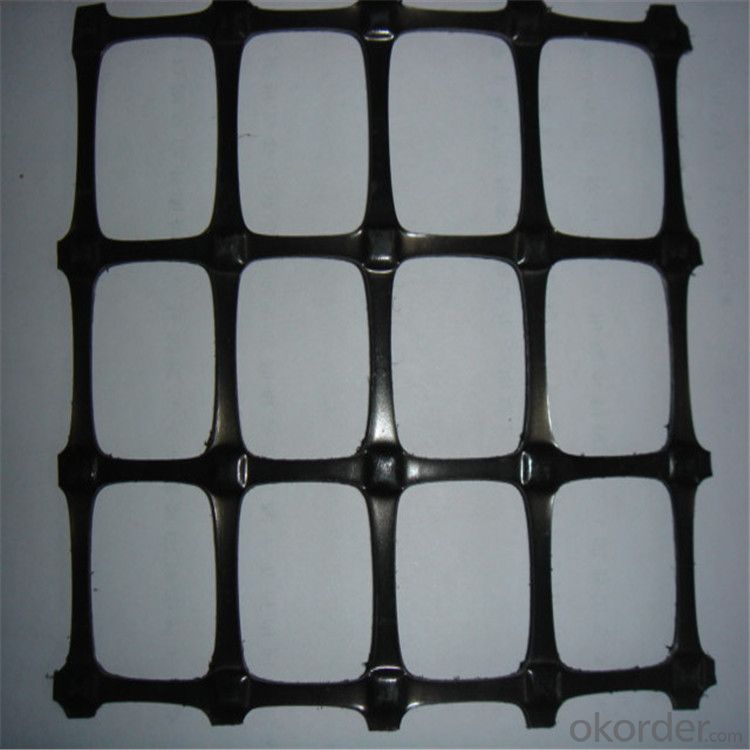

Biaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched into regular mesh pattern, and finally stretched in longitudinal and transverse directions.

Features:

1. With high tensile strength in longitudinal and transverse directions

2.This structure can provide an chain system of more effective force bearing and spreading for the soil.

Application:

Mainly applied in highway, railway, slope protecting projects etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ;

reducing project cost and maintenance cost.

Properties of PP Biaxial Geogrid (Test Method: ASTM D 6637)

Specification | EGA30-30 | EGA50-50 | EGA80-80 | EGA100-100 | EGA120-120 | |

Mesh size(mm) | 25.4×25.4 Or 12.5×12.5 | |||||

Breaking strength ≥(KN/m) | Warp direction | 30 | 50 | 80 | 100 | 120 |

Across warp | 30 | 50 | 80 | 100 | 120 | |

Elongation at break ≤(%) | Warp direction | 3 | ||||

Across warp | 3 | |||||

Elasticity modulus(GPA) | 67 | |||||

Thermal tolerance | -100~280℃ | |||||

Width | 1~6m | |||||

Item Spec | TGSG 15-15 | TGSG 20-20 | TGSG 25-25 | TGSG 30-30 | TGSG 35-35 | TGSG 40-40 | TGSG 45-45 | TGSG 50-50 | ||

Tensile Strength ≧(Kn/m) | MD | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | |

TD | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | ||

Nominal Elongation ≦(%) | MD | 15 | ||||||||

TD | 13 | |||||||||

Tensile Strength at 2% Strain ≧(Kn/m) | MD | 5 | 7 | 9 | 10.5 | 12 | 14 | 16 | 17.5 | |

TD | 5 | 7 | 9 | 10.5 | 12 | 14 | 16 | 17.5 | ||

Tensile Strength at 5% Strain ≧(Kn/m) | MD | 7 | 14 | 17 | 21 | 24 | 28 | 32 | 35 | |

TD | 7 | 14 | 17 | 21 | 24 | 28 | 32 | 35 | ||

Junction Efficiency (%) | 93 | |||||||||

Width ≦(m) | 6 | |||||||||

Note: MD: Machine direction

TD: Transverse direction

Images of PP Biaxial Geogrid

- Q:Are geogrids effective in preventing soil erosion on slopes without vegetation?

- Yes, geogrids can be effective in preventing soil erosion on slopes without vegetation. Geogrids are engineered materials made from synthetic polymers, which are typically placed within the soil to reinforce it and provide stability. They help to distribute the forces acting on the soil and increase its shear strength, thus reducing the risk of erosion. However, it is important to note that geogrids alone may not be a long-term solution. It is recommended to combine them with other erosion control measures, such as hydroseeding or erosion control blankets, to achieve optimal results.

- Q:Are geogrids suitable for use in slope reinforcement during excavation?

- Yes, geogrids are suitable for use in slope reinforcement during excavation. Geogrids are commonly used in slope stabilization and reinforcement projects due to their high tensile strength and ability to distribute loads. They can effectively prevent soil erosion and provide stability to slopes during excavation, making them a reliable choice for such applications.

- Q:What are the factors affecting the durability of geogrids?

- The factors affecting the durability of geogrids include the material composition of the geogrid, the quality of the manufacturing process, exposure to UV radiation, chemical exposure, temperature fluctuations, installation techniques, and the level of stress or load placed on the geogrid.

- Q:What are the design considerations for geogrid-reinforced structures?

- Some design considerations for geogrid-reinforced structures include the type and strength of the geogrid material, the soil characteristics and conditions, the required structural integrity and stability, the anticipated loads and stresses, the desired lifespan of the structure, and the overall cost-effectiveness of the design. Additionally, factors such as installation and construction techniques, environmental impacts, and local regulations may also need to be taken into account during the design process.

- Q:What are the application of Geogrid in the construction of cement concrete pavement

- Moreover, as the reinforcement material, can make the road slightly increased the tensile strength, can extend the service life of the road, shorten the construction period

- Q:How do geogrids help in reducing the risk of settlement of structures?

- Geogrids help in reducing the risk of settlement of structures by providing reinforcement and stability to the soil. They are placed within the soil layer to distribute and transfer the load more evenly, thereby reducing the potential for settlement. By increasing the soil's strength and load-bearing capacity, geogrids help prevent excessive settlement and improve the overall stability and longevity of the structures.

- Q:Can geogrids be used in floating road construction?

- Yes, geogrids can be used in floating road construction. Geogrids are often used to reinforce and stabilize the subgrade in road construction projects, including floating roads. They provide additional strength and stability to the road structure, allowing it to withstand heavy loads and prevent deformation.

- Q:Are geogrids suitable for reinforcement of soft subgrades?

- Yes, geogrids are suitable for reinforcement of soft subgrades. Geogrids are specifically designed to enhance the stability and strength of weak soils, such as soft subgrades. By distributing the load and improving soil confinement, geogrids can effectively reduce settlement and improve the overall performance of the subgrade.

- Q:How do geogrids enhance the performance of flexible retaining structures?

- Geogrids enhance the performance of flexible retaining structures by providing reinforcement and stability to the soil. They distribute the loads more evenly, reducing the stress on the structure and increasing its overall strength. Geogrids also prevent soil erosion and improve drainage, ensuring the long-term integrity and durability of the retaining structure.

- Q:Geogrid grille read Shan or Zha?

- The traditional geogrid is mainly plastic grille and glass fiber grid, but because of the large deformation of plastic grille and glass fiber grille is mainly suitable for the reasons of the road engineering, and a new type of steel plastic composite geogrid.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PP Biaxial Geogrid with High Tensile Strength Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords