Polyester Short Fiber Needle Punched Nonwoven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polyester Short Fiber Needle Punched Nonwoven Geotextile

1. Product Description:

Needle punched nonwoven Geotextiles are made of polyester or polypropylene in random directions and punched together by needles.

Geotextiles has good impermeability and resistance to deformation, which allows geotextiles be widely applied in civil projects for separation,filtration,reinforcement, protection and drainage.

Geotextiles can be used as:

* Filtration or separation layers in civil engineering projects of roads and railway construction;

* Protect layer for geomembranes in landfill construction;

* Coastal defence applications

* Landscaping projects to maintain soil and protect land surfaces and structures from weeds and root growth.

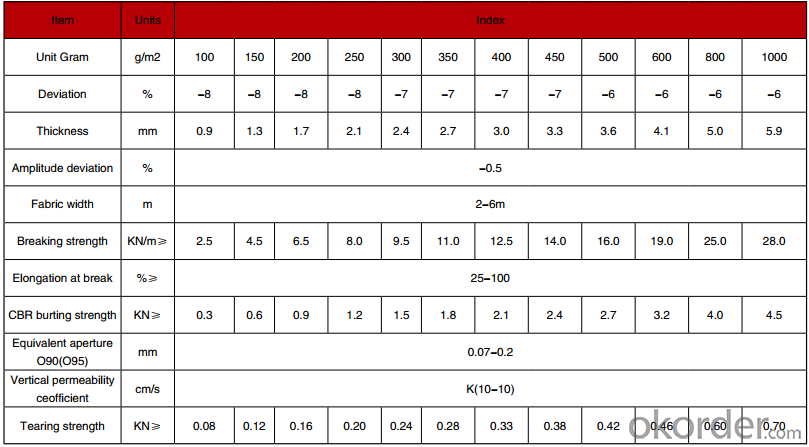

2. Data sheet:

3. Main Features

2) High temperature resistance to up to 230℃ maintaining structure stability and original physical properties;

3) High flat drainage and vertical permeability;

4) High creep resistance;

5) Resistance of erosion of chemicals in soil as well as the corrosion of gasoline and diesel etc;

6) High elongation under certain stress, thus able to adapt to uneven and irregular bases;

4. Packaging & Shipping:

white fabric bag or black PE bag outside or as required.

7 days after received deposite

5. Applications of NON-Woven Geotextile :

Non woven Geotextiles can be widely used in railways, highways, sports halls, ,garbage dump ,dams, hydraulic construction, tunnels, coastal beaches, land reclamation, environmental protection and other projects.

Notes : The specification is based on mass area ratio.

When the actual specification is between adjacent specifications in this table, it is necessary to calculate the corresponding evaluation indicators in accordance with the interpolation method;

If the range in table is exceeded, it is necessary to determine the evaluation indicators through consultation by the supply and demand sides.

6.Pictures

7. FAQ:

Q1: Can you provide a sample for us?

A:Yes,We can send free samples,but customer need to pay the freight.

Q2: What is your minimum order quantity?

A:The minimum order quantity is 5000,but it is negotiable.

Q3:What is your payment terms?

A: T/T,Western Union,L/C.

Q4:What is your delivery time?

A:Production time usually costs 2-20 days.

- Q:How do geotextiles reduce hydraulic pressure in soil?

- Geotextiles reduce hydraulic pressure in soil by acting as a barrier that allows water to pass through while preventing soil particles from being washed away. This allows for better drainage and prevents the build-up of excess water pressure in the soil.

- Q:Can geotextiles be used in river training works?

- Yes, geotextiles can be used in river training works. They are often used to reinforce riverbanks, control soil erosion, and stabilize the riverbed. Geotextiles can help manage water flow, prevent sedimentation, and improve overall river stability.

- Q:Can the nonwoven geotextile be used to hold the soil

- Yes, the soil is not lost on the line, ground watering, if the balcony need to consider good health problems. More vegetables on the issue of "pan rice race vegetables Q & A network

- Q:Performance index of composite geotextile

- Item Unit Area Quality g / m000 Remark Film Thickness mm0.25-0.350.3-0.5 Fracture strength KN / m57.510.012.014.016.018.0 Longitudinal transverse elongation% 30-100CBR Breaking strength KN≥1.11.51.92. 22.52.83.0 Tearing strength KN≥0.150.250.320.40.480.560.62 Vertical and horizontal peel strength N / cm6 Vertical and horizontal permeability coefficient cm / sk * 10-11-10-13k = 1.0-9.9

- Q:Geotechnical deployment of aging detection of what indicators

- Material anti-aging performance testing, if the reality to consider, for too long, are generally used in the laboratory to accelerate the aging approach to consider. Aging the concept of aging is a big concept. Refers to the material in the external environment under the influence of time changes. Environmental effects are multifaceted, the role of light, the role of temperature, a chemical role, the role of micro-organisms and so on. Now generally referred to as aging, refers to the light aging. Light aging, refers to the material in a certain light exposure after a certain period of time after the performance of the material changes. The most commonly used indicator for photoaging is the strength retention of the material. That is, the ratio of the strength that remains after the light is retained.

- Q:How do geotextiles help with soil separation in subgrade improvement projects?

- Geotextiles are used in subgrade improvement projects to separate different soil layers, preventing them from mixing. They act as a barrier, allowing water to pass through while preventing the migration of fine particles. This helps to maintain the stability and strength of the subgrade, reducing the risk of settlement and soil erosion.

- Q:How do geotextiles help with soil reinforcement in mechanically stabilized earth walls?

- Geotextiles help with soil reinforcement in mechanically stabilized earth walls by providing a strong and stable base for the soil. They distribute the load evenly, reducing the risk of soil erosion and increasing the wall's stability. Additionally, geotextiles improve the soil's drainage capabilities, preventing water buildup and further enhancing the wall's structural integrity.

- Q:How do geotextiles help with reinforcement of geosynthetic clay liner slopes?

- Geotextiles provide reinforcement to geosynthetic clay liner slopes by adding tensile strength and stability to the structure. They act as a barrier against soil erosion and prevent the clay liner from sliding or slumping. Geotextiles also enhance the overall performance and longevity of the slope by distributing load and reducing stress on the liner.

- Q:Are geotextiles suitable for use in geotextile tube dewatering systems?

- Yes, geotextiles are suitable for use in geotextile tube dewatering systems. Geotextiles are commonly used in these systems to provide filtration and separation of water from solids. They allow water to pass through while retaining the solids, making them an effective solution for dewatering and sediment containment projects.

- Q:What are the specifications for geotextiles in civil engineering projects?

- Geotextiles used in civil engineering projects have specific specifications that include factors such as weight, tensile strength, permeability, and durability. The weight of the geotextile is typically measured in grams per square meter (gsm) and can vary depending on the specific application. Tensile strength refers to the material's ability to resist breaking under tension and is measured in units like kilonewtons per meter (kN/m). Permeability is a crucial factor, as geotextiles should allow water to pass through while preventing the movement of soil particles. Lastly, durability is essential to ensure the geotextile can withstand the environmental conditions it will be exposed to, such as UV exposure or chemical resistance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polyester Short Fiber Needle Punched Nonwoven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords